Delayed coking method and apparatus for heavy oil

A delayed coking and heavy oil technology, applied in cracking, petroleum industry, non-catalytic thermal cracking, etc., can solve the problems of not reducing the water injection of coking furnace, increasing the heat load of heating furnace, and coking of heating furnace tube, so as to reduce water vapor The effect of consumption, reduction of processing energy consumption and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

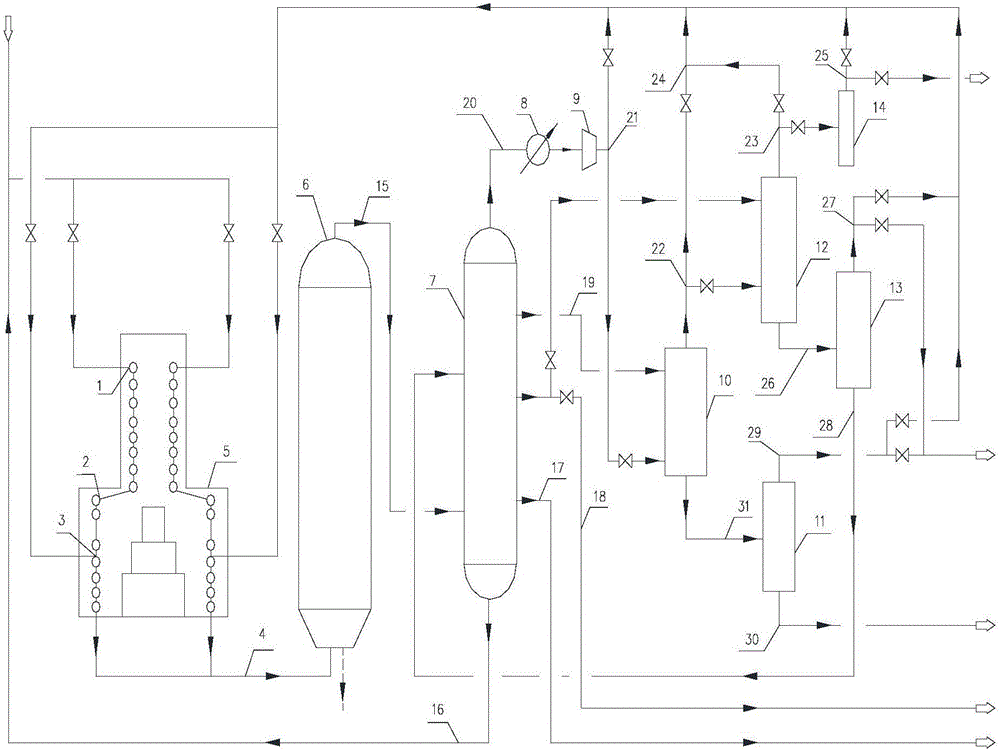

[0052] A method for delayed coking of heavy oil, comprising the steps of:

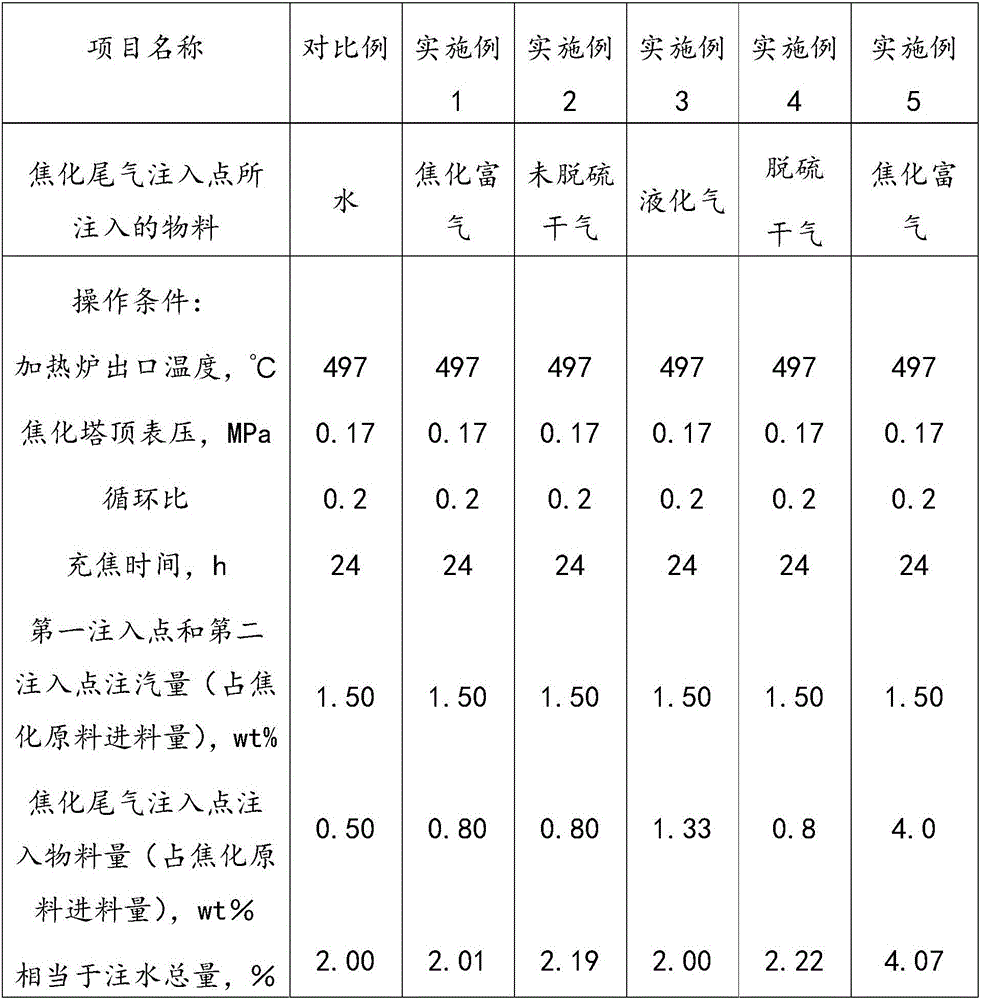

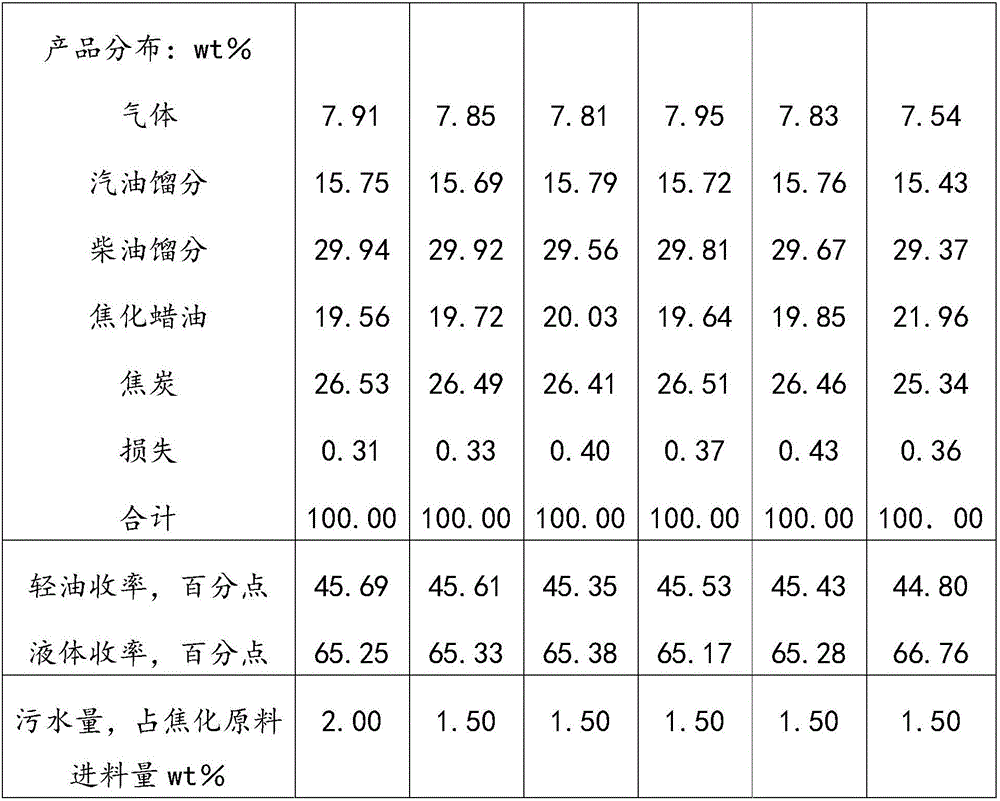

[0053] use figure 1 The heavy oil delayed coking unit shown uses vacuum residue as coking raw material (see Table 1 for the properties of vacuum residue), the temperature at the outlet of heating furnace 5 is 497°C, the pressure at the top of coking tower 6 is 0.17Mpa, the first injection point and the second The total amount of water injection at the second injection point accounts for 1.5wt% (0.75wt%) of the coking raw material feed amount and under the condition of a circulation ratio of 0.2, the high-temperature material from the outlet of the radiant section of the heating furnace 5 enters the coking tower 6 for coking reaction The high-temperature oil and gas generated enters the fractionation tower 7 for separation after quenching; the coking rich gas (C1-C4 components) obtained from the top of the fractionation tower 7 through cooling and separation is pressurized to about 1.2MPa by the rich ga...

Embodiment 2

[0057] Use the method and device described in Example 1 to carry out delayed coking of heavy oil, the difference is that only the dry gas before desulfurization from the gasoline absorption and recirculation dry gas pipeline 24 replaces the coking rich gas and enters the radiant section of the heating furnace 5, which is the fourth from bottom to top Furnace tube 3.

Embodiment 3

[0059] Using the method and device described in Example 1 to carry out delayed coking of heavy oil, the difference is that only the liquefied gas from the liquefied gas pipeline replaces the coking rich gas and enters the fourth furnace tube 3 from bottom to top in the radiant section of the heating furnace 5, and its injection volume accounts for 1.33wt% of the coking raw material feed amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com