Process of preparing aromatic hydrocarbons and liquefied petroleum gas from hydrocarbon mixture

一种液化石油气、烃混合物的技术,应用在处理烃油、烃油裂解、石油工业等方向,达到好经济效益、高增值的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

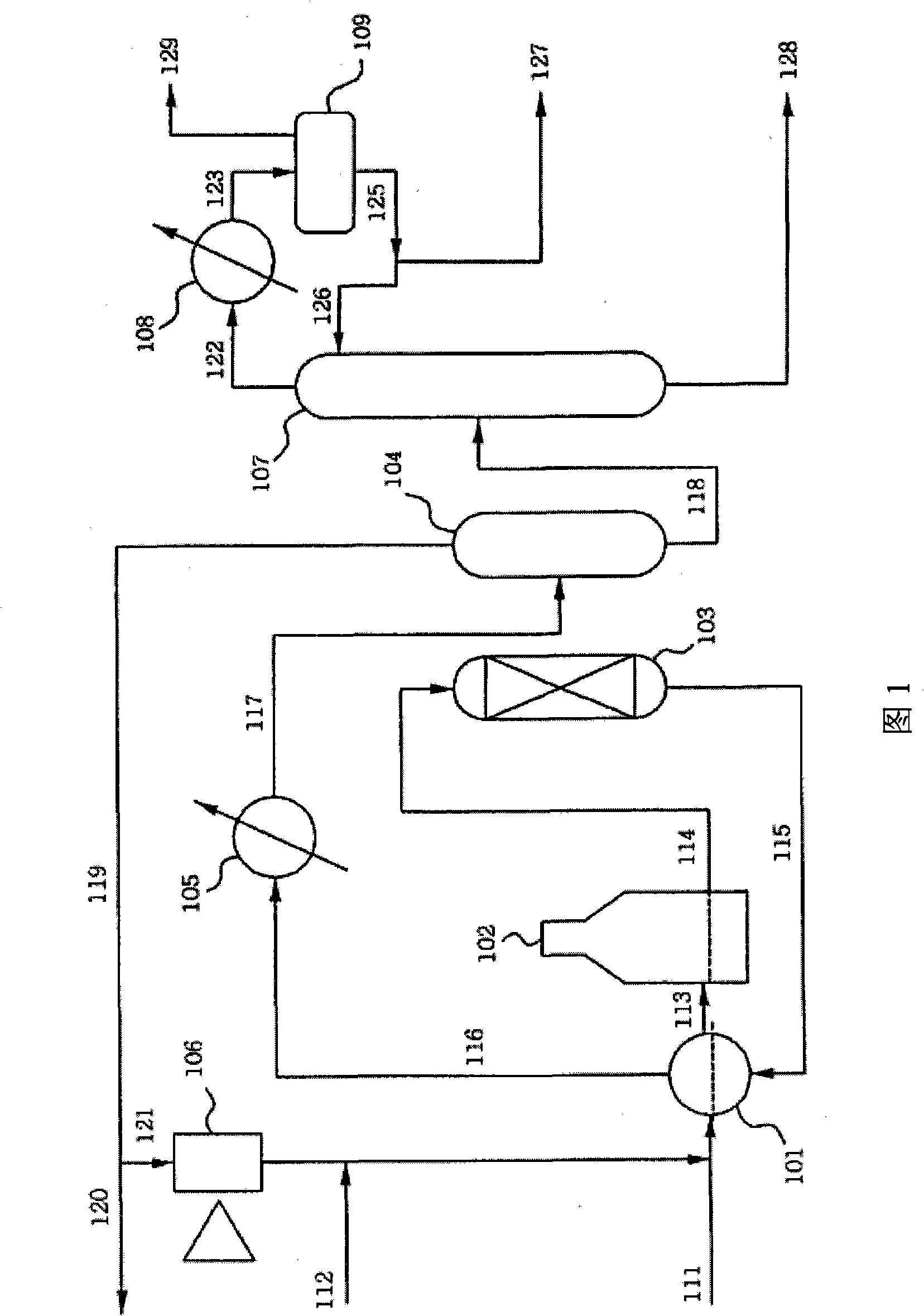

Method used

Image

Examples

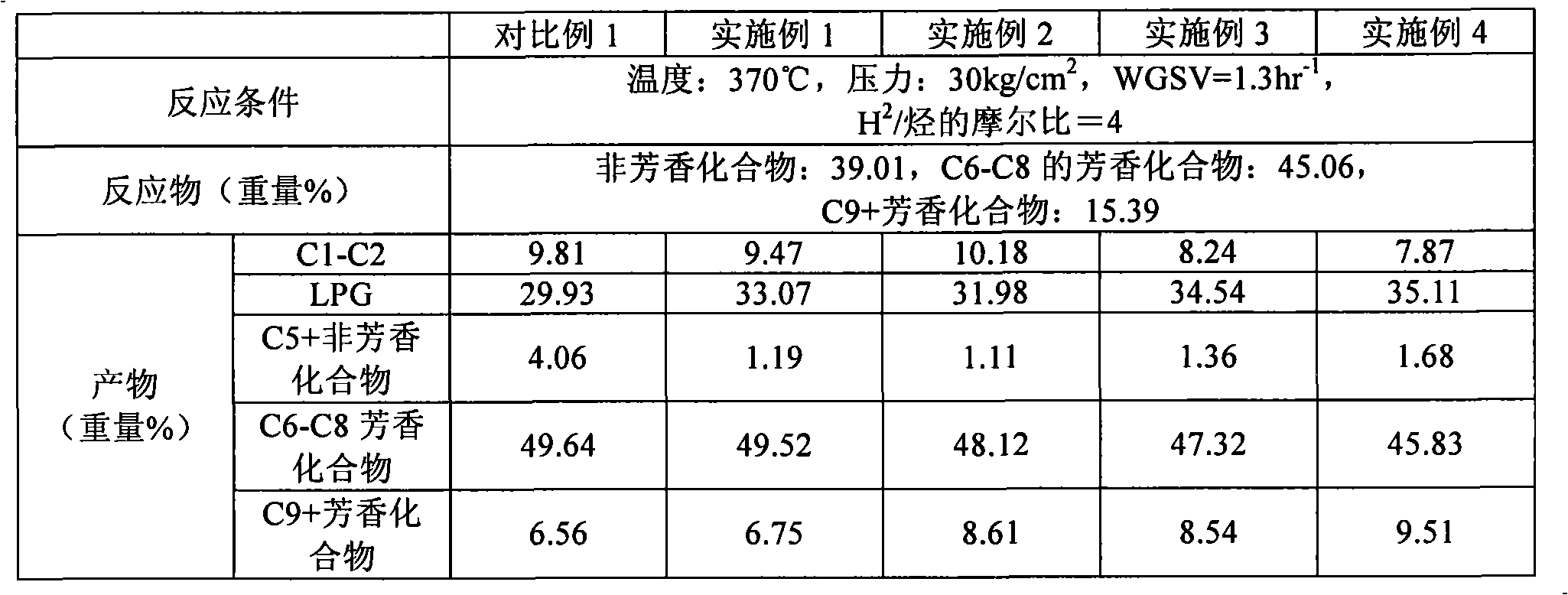

Embodiment 1

[0068] mix carrier with H 2 PtCl 6 aqueous solution and Bi(NO 3 ) 3 The aqueous solution is mixed, the mixture carrier contains ZSM-5 zeolite and gamma-alumina as a binder, the silica / alumina molar ratio of the zeolite is 30, in addition to platinum and bismuth, ZSM-5 in the carrier The amount of zeolite is 75% by weight. The supported amounts of platinum and bismuth were 0.03 parts by weight and 0.5 parts by weight, respectively, relative to 100 parts by weight of ZSM-5 zeolite and the binder in total. The supported mixture carrier was molded to have a diameter of 2 mm and a length of 10 mm, dried at 120° C. for 3 hours, and then calcined at 500° C. for 3 hours, thereby preparing a catalyst. The prepared catalyst is used for hydrocarbon mixture reaction. The reaction conditions and reaction results are shown in Table 1 below.

Embodiment 2

[0070] mix carrier with H 2 PtCl 6 aqueous solution and BiCl 3 The aqueous solution is mixed, the mixture carrier contains ZSM-5 zeolite and gamma-alumina as a binder, the silica / alumina molar ratio of the zeolite is 30, in addition to platinum and bismuth, ZSM-5 in the carrier The amount of zeolite is 75% by weight. The supported amounts of platinum and bismuth were 0.03 parts by weight and 0.25 parts by weight, respectively, relative to 100 parts by weight of the ZSM-5 zeolite and the binder in total. The loaded mixture carrier was molded to have a diameter of 2 mm and a length of 10 mm, dried at 120° C. for 3 hours, and then calcined at 500° C. for 3 hours, thereby preparing a catalyst. The prepared catalyst is used for hydrocarbon mixture reaction. The reaction conditions and reaction results are shown in Table 1 below.

Embodiment 3

[0072] mix carrier with H 2 PtCl 6 aqueous solution and BiCl 3 The aqueous solution is mixed, and the mixture carrier contains ZSM-5 zeolite with a silica / alumina molar ratio of 30, mordenite with a silica / alumina molar ratio of 20 and gamma-alumina as a binder, In addition to platinum and bismuth, the amounts of ZSM-5 zeolite and mordenite in the support were 50% by weight and 25% by weight, respectively. The supported amounts of platinum and bismuth were 0.03 parts by weight and 0.25 parts by weight, respectively, relative to 100 parts by weight of ZSM-5 zeolite, mordenite and binder in total. The supported mixture carrier was molded to have a diameter of 2 mm and a length of 10 mm, dried at 120° C. for 3 hours, and then calcined at 500° C. for 3 hours, thereby preparing a catalyst. The prepared catalyst is used for hydrocarbon mixture reaction. The reaction conditions and reaction results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com