Method for preparing superfine zinc tungstate antibacterial agent by ultrasonic molten salt method

A molten salt method, zinc tungstate technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of uneven particle size distribution, high reaction temperature, silver-based antibacterial agents are easily oxidized and discolored, etc. To achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

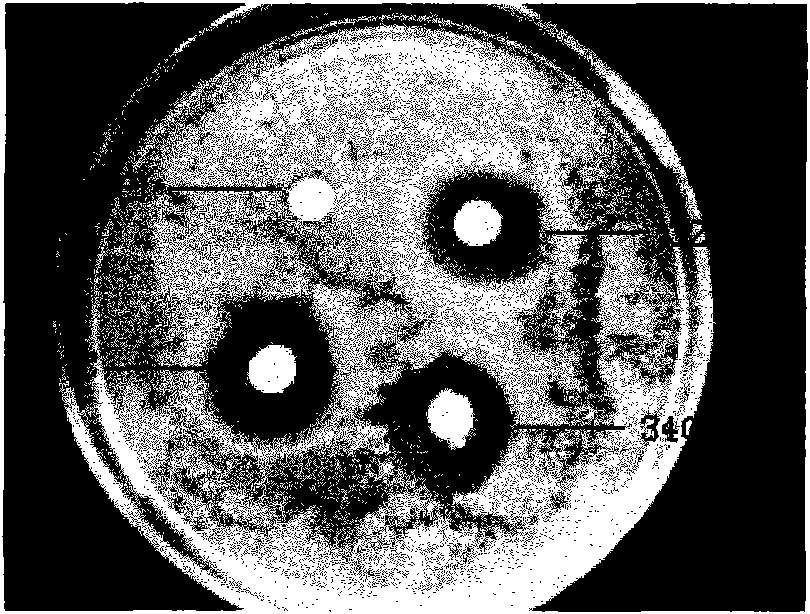

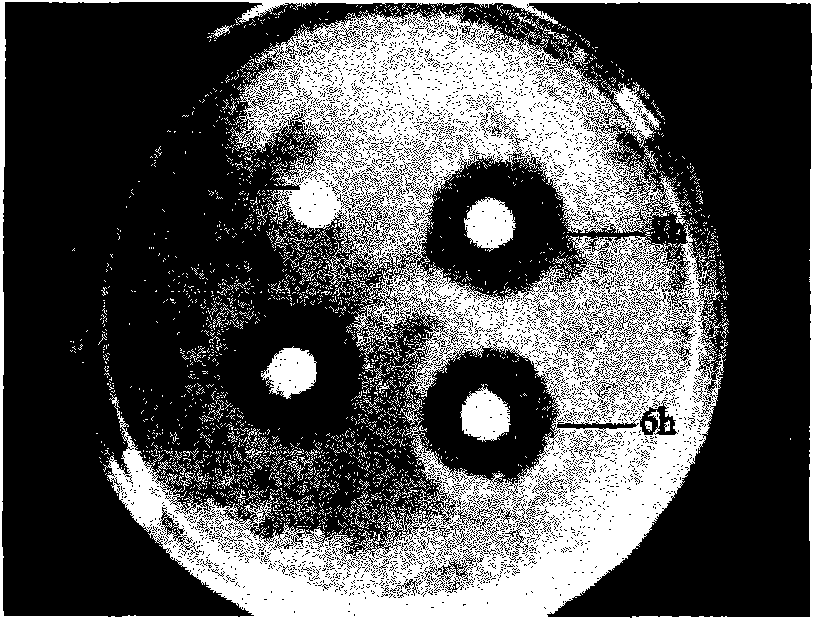

[0029] Example 1 Na 2 WO 4 And Zn(NO 3 ) 2 Respectively formulated into an aqueous solution with a concentration of 0.2mol / L, and then Na 2 WO 4 Add Zn(NO 3 ) 2 In aqueous solution, make Na 2 WO 4 With Zn(NO 3 ) 2 The molar ratio of is 1:1; a total of 50 mL of the mixed solution is prepared; the reaction is carried out under ultrasonic heating at 20°C to 40°C under stirring conditions for 15 minutes to 45 minutes, so that the mixed solution is fully reacted and mixed. The mixed solution is filtered, washed with distilled water, and dried at 90°C for 5 hours to obtain ZnWO 4 Precursor.

Embodiment 2

[0030] Example 2 ZnWO with a molar ratio of 1:5 by weight and a total of 15g 4 Precursor and NaNO 3 Mix the salt and add 2~3mL absolute ethanol in the mortar and mix for 2h while grinding to make ZnWO 4 The precursor and the reaction medium are thoroughly mixed uniformly, and then dried at 90°C for 5 hours, then placed in an electric furnace at 360°C for 8 hours, and cooled to obtain a solidified product. Fully soak and wash the solidified product with distilled water, then filter and dry to remove the remaining molten salt, you can get ZnWO 4 Antibacterial powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com