Method for preparing ordered porous energetic crystal material

A crystal material and crystal technology, which is applied in the field of preparation of ordered porous energetic crystal materials, can solve the problem of not obtaining ordered porous energetic materials and the like, and achieve the effects of easy control of reaction conditions, simple process flow and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

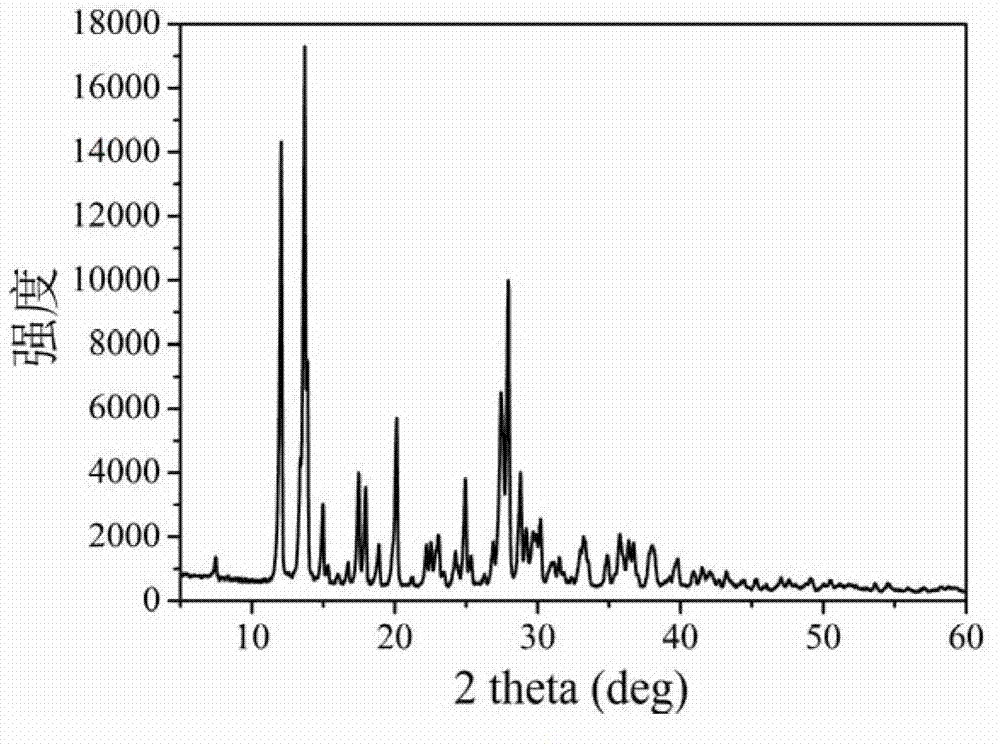

[0026] The preparation method steps of ordered porous CL-20 are as follows:

[0027] Take 0.1g of CL-20 at room temperature and dissolve it in 5ml of nitrogen-nitrogen dimethylformamide under the condition of magnetic stirring at a speed of 500 rpm, and stir until CL-20 is completely dissolved.

[0028] Take 0.05g of calix[4]arene and add it into the solution, and continue stirring until the calix[4]arene is completely dissolved.

[0029] Under the condition of stirring, add the solution dropwise to 50ml double distilled water, and the CL-20 / cup[4]arene compound slowly precipitates out. Stirring was continued for 30 minutes, filtered, and vacuum-dried at 50° C. for 12 hours to obtain CL-20 / calix[4]arene complex.

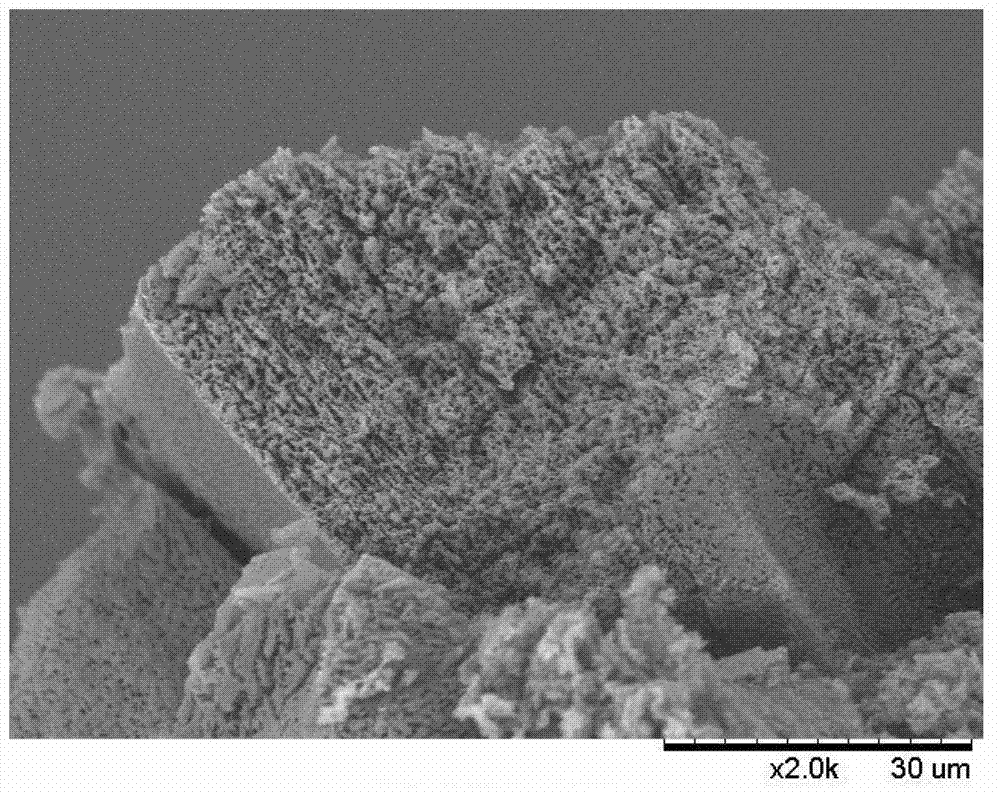

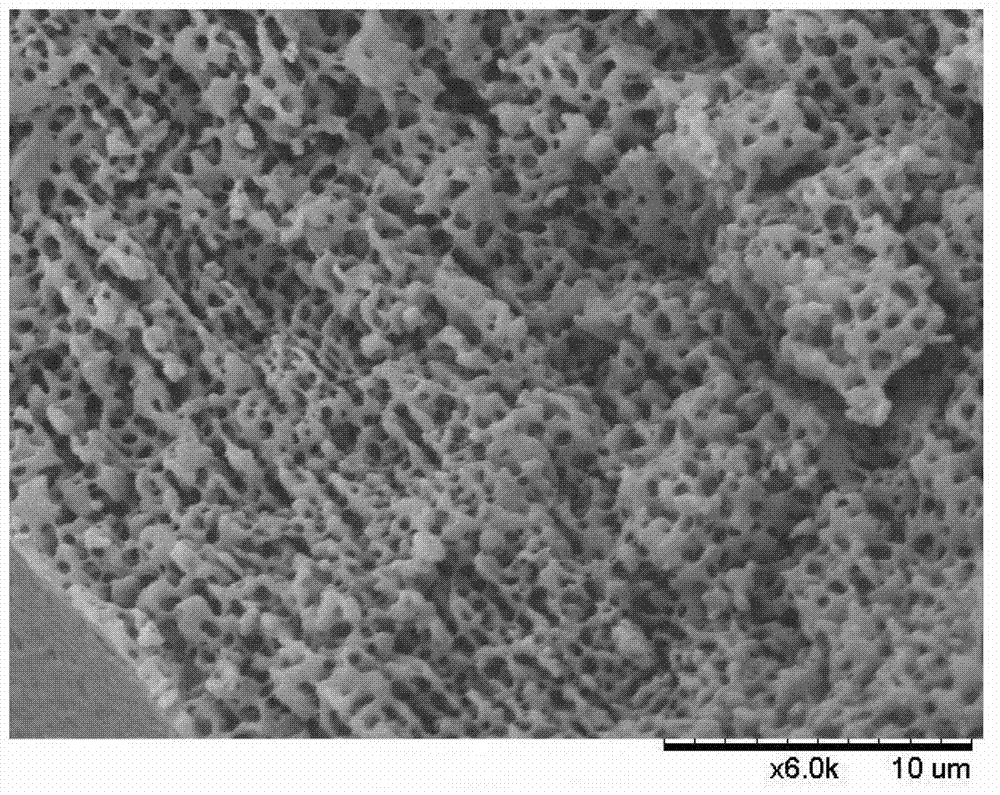

[0030] Take 0.1g of CL-20 / cup[4]arene compound and put it into 100ml double distilled water, wash it under magnetic stirring at 100rpm, so that the calix[4]arene compound in the compound is slowly dissolved, and repeat the washing several times to remove Calix[4]ar...

Embodiment 2

[0033] The preparation method steps of ordered porous CL-20 are as follows:

[0034] Take 0.1g of CL-20 at room temperature and dissolve it in 5ml of nitrogen-nitrogen dimethylformamide under the condition of magnetic stirring at a speed of 500 rpm, and stir until CL-20 is completely dissolved.

[0035] Add 0.05g of β-cyclodextrin into the solution and continue stirring until the β-cyclodextrin is completely dissolved.

[0036] Under the condition of stirring, add the solution dropwise into 50ml double-distilled water, the CL-20 / β-cyclodextrin complex slowly precipitates, continue to stir for 30 minutes, filter, and vacuum dry at 50°C for 12h to obtain CL-20 / β-cyclodextrin complex β-cyclodextrin complex.

[0037] Take 0.1g of CL-20 / β-cyclodextrin complex and put it into 100ml double-distilled water, and wash it under magnetic stirring at 100rpm to slowly dissolve the β-cyclodextrin in the complex, and repeat the washing several times to remove β-cyclodextrin in CL-20 / β-cyclo...

Embodiment 3

[0039] The preparation method steps of ordered porous HMX are as follows:

[0040] At room temperature, 0.1 g of HMX was dissolved in 5 ml of nitrogen-nitrogen dimethylformamide under magnetic stirring at a speed of 500 rpm, and stirred until the HMX was completely dissolved.

[0041] Take 0.05g of calix[8]arene and add it into the solution, and continue stirring until the calix[8]arene is completely dissolved.

[0042] Under the condition of stirring, add the solution dropwise to 50ml double-distilled water, CL-20 / cup[8]arene complex slowly precipitates, continue to stir for 30 minutes, filter, and vacuum dry at 50°C for 12h to obtain HMX / cup[8] 8] Aromatic Complex.

[0043]Take 0.1g of HMX / calix[8]arene complex and put it into 100ml double distilled water, wash it under magnetic stirring at 100rpm to slowly dissolve the calix[8]arene in the complex, repeat the washing several times to remove HMX Calix[8]arene in a calix[8]arene complex, filtered, and dried to give ordered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com