Preparation method of Ni-Co-Mn lithium ion battery electrode material

An ion electrode, nickel-cobalt-manganese-lithium technology, which is applied in the field of preparation of nickel-cobalt-manganese-lithium ion electrode materials to achieve the effects of improving electrochemical performance and reducing capacity decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

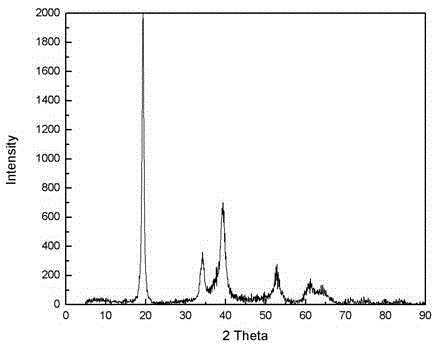

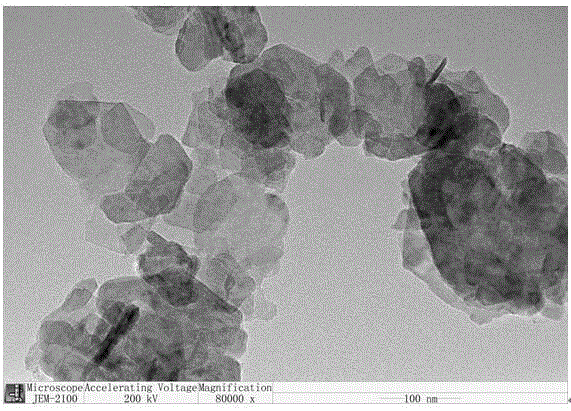

Image

Examples

Embodiment 1

[0021] (1) Dissolve polyvinylpyrrolidone-K30 in distilled water at a ratio of 6g / ml to obtain mixed solution A, and adjust the pH of the solution to 10.0 with 25% ammonia solution;

[0022] (2) Press NiSO 4 , MnSO 4 , CoSO 4 According to the molar ratio of Ni:Mn:Co=5:3:2, use distilled water to prepare nickel-cobalt-manganese mixed salt solution B, the total concentration of metal ions in the solution is 4mol / L; use distilled water to prepare mixed solution C of sodium hydroxide and ammonia water , wherein the concentration of sodium hydroxide solution is 4mol / L, and the concentration of ammonia water is 2mol / L;

[0023] (3) First add the prepared mixed solution A into the reaction kettle as the reaction bottom liquid, then add the prepared solution B and solution C dropwise into the 500ml volume reaction kettle at the same time (the temperature is 60 ℃) for stirring, in the Under the protection of nitrogen, the precipitate obtained by the reaction under ultrasonic cavitati...

Embodiment 2

[0027] (1) Dissolve polyvinylpyrrolidone-K30 in distilled water at a ratio of 4g / ml to obtain mixed solution A, and adjust the pH of the solution to 11 with 25% ammonia solution;

[0028] (2) The NiSO 4 Prepare nickel sulfate solution B with distilled water, and the total concentration of metal ions in the solution is 0.5mol / L; prepare mixed solution C of sodium hydroxide and ammonia water with distilled water, wherein the concentration of sodium hydroxide solution is 1mol / L, and the concentration of ammonia water is 0.4mol / L;

[0029] (3) First add the prepared mixed solution A into the reaction kettle as the reaction bottom liquid, then add the prepared solution B and solution C dropwise to the 500ml volume reaction kettle (temperature is 40 ℃) at the same time for stirring, Under the protection of nitrogen, the precipitation obtained by the reaction for 45 min under ultrasonic cavitation is nickel hydroxide; wherein, the ultrasonic power is controlled at 600W per liter of ...

Embodiment 3

[0033] (1) Dissolve polyvinylpyrrolidone-K30 in distilled water at a ratio of 10g / ml to obtain mixed solution A, and adjust the pH of the solution to 12.0 with 25% ammonia solution;

[0034] (2) MnSO 4 Prepare nickel sulfate solution B with distilled water, the total concentration of metal ions in the solution is 1mol / L; prepare mixed solution C of sodium hydroxide and ammonia water with distilled water, wherein the concentration of sodium hydroxide solution is 2mol / L, and the concentration of ammonia water is 2mol / L;

[0035] (3) First add the prepared mixed solution A into the reaction kettle as the reaction bottom liquid, then add the prepared solution B and solution C dropwise to the 500ml volume reaction kettle (at a temperature of 50°C) at the same time for stirring. Under the protection of nitrogen, the precipitation obtained by the reaction for 42 min under ultrasonic cavitation is manganese hydroxide; wherein, the ultrasonic power is controlled at 1800W per liter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com