Method for preparing full-silicon DD3R zeolite molecular sieve with pure phase and uniform crystal morphology and size

A zeolite molecular sieve, all-silicon technology, applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve the problems of poor product quality, low repetition rate and high cost, achieve high quality and reduce synthesis energy. consumption and shortening the crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

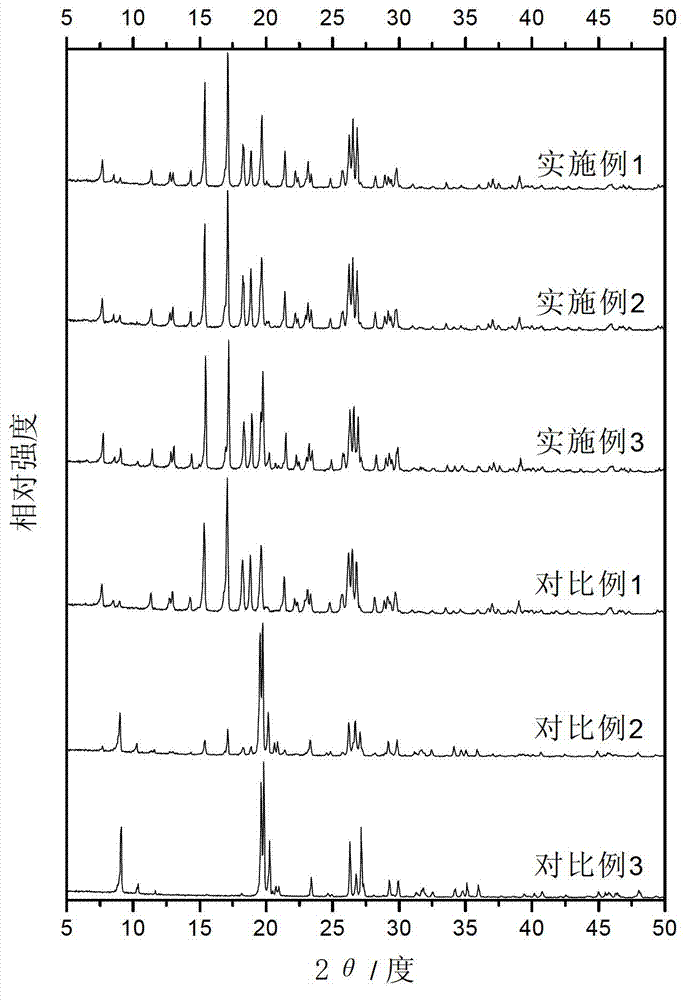

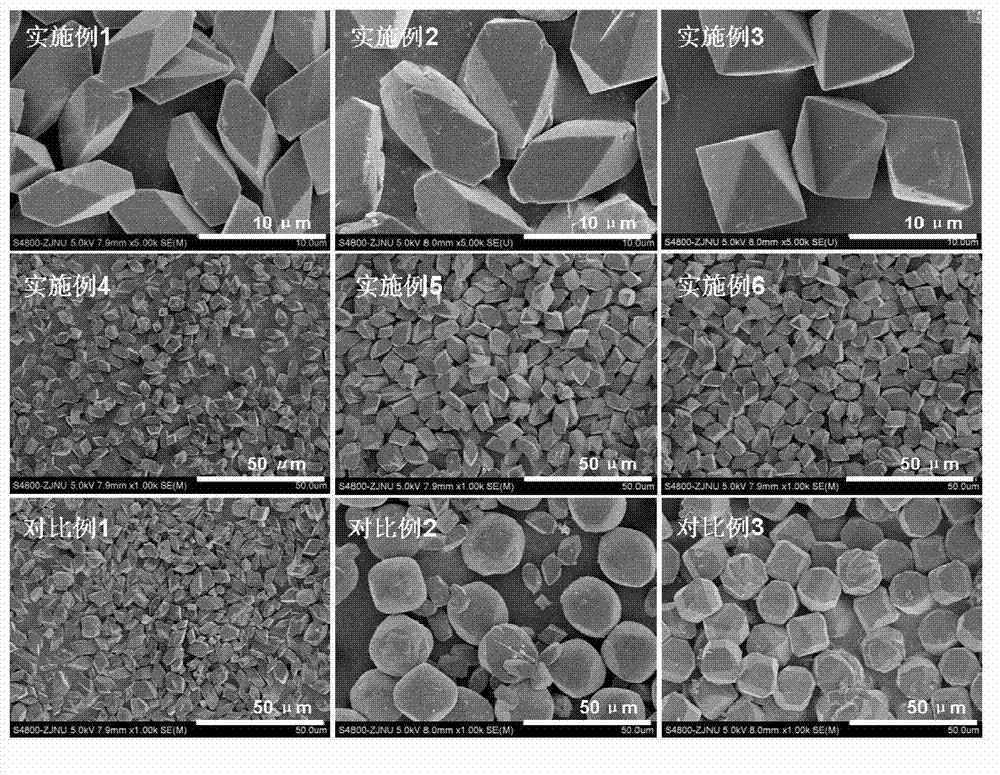

[0021] Dissolve 3 mL of silicon source in 30 mL of deionized water, stir vigorously, and add 1.6 g of amantadine. After stirring for a while, add 1.3 g of KF to obtain a mixed solution. Add 0.036g of seed crystals to the mixed system obtained in the above steps, mix and stir for 2 hours, transfer to a 50mL hydrothermal reaction kettle, and place it at 170°C for crystallization for 1 day; filter the obtained sample with deionized water Wash, dry at 110°C for 12 hours, and then bake in a muffle furnace at 700°C for 8 hours to obtain a sample. The XRD spectrum of the sample is shown in figure 1 -Example 1, as can be seen from the characterization diagram, the characteristic diffraction peaks of DD3R molecular sieves appeared at 2θ=7.68°, 15.39° and 17.13°, indicating that the synthesized sample is DD3R molecular sieve; the SEM photo is shown in figure 2 -Example 1, the DD3R molecular sieve crystal in the figure has a clear outline, regular shape, parallelepiped, and a grain siz...

Embodiment 2

[0023] Dissolve 3 mL of silicon source in 30 mL of deionized water, stir vigorously, and add 0.8 g of amantadine. After stirring for a while, add 2.6 g of KF to obtain a mixed solution. Add 0.036g of seed crystals to the mixed system obtained in the above steps, mix and stir for 2 hours, transfer to a 50mL hydrothermal reaction kettle, and place it at 170°C for crystallization for 1 day; filter the obtained sample with deionized water Wash, dry at 110°C for 12 hours, and then bake in a muffle furnace at 700°C for 8 hours to obtain a sample. The XRD spectrum of the sample is shown in figure 1 -Example 2, it can be seen from the characterization diagram that the characteristic diffraction peaks of DD3R molecular sieve appear at 2θ=7.68°, 15.39° and 17.13°, indicating that the synthesized sample is DD3R molecular sieve. SEM photo see figure 2 -Example 2, the DD3R molecular sieve crystals in the figure have clear outlines, regular shapes, parallelepipeds, and a grain size of ab...

Embodiment 3

[0025] Dissolve 3 mL of silicon source in 25 mL of deionized water, stir vigorously, and add 1.6 g of amantadine. After stirring for a while, add 1.3 g of KF to obtain a mixed solution. Add 0.036g of seed crystals to the mixed system obtained in the above steps, mix and stir for 2 hours, then transfer to a 50mL hydrothermal reaction kettle, and crystallize at 170°C for 3 days; filter the obtained samples with deionized water Wash, dry at 110°C for 12 hours, and then bake in a muffle furnace at 700°C for 8 hours to obtain a sample. The XRD spectrum of the sample is shown in figure 1-Example 3, it can be seen from the characterization diagram that the characteristic diffraction peaks of DD3R molecular sieve appear at 2θ=7.68°, 15.39° and 17.13°, indicating that the synthesized sample is DD3R molecular sieve. SEM photo see figure 2 -Example 3, the DD3R molecular sieve crystal in the figure has a clear outline, regular shape, regular octahedron, and a grain size of about 8 μm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com