Surface treatment composite additive capable of improving corrosion resistance of copper foil

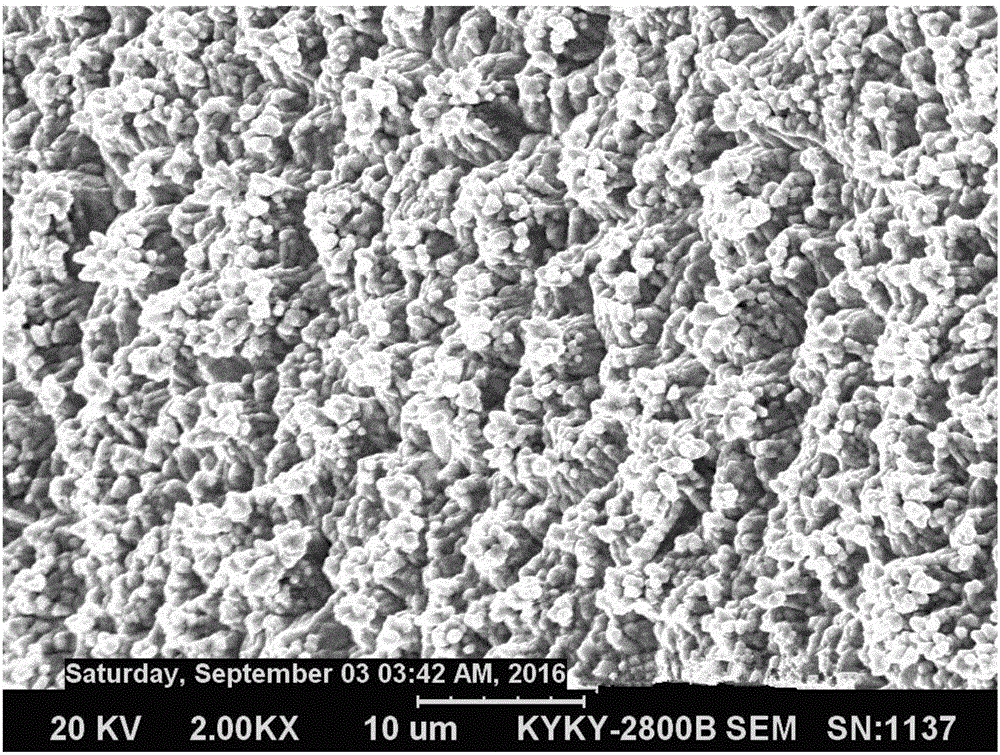

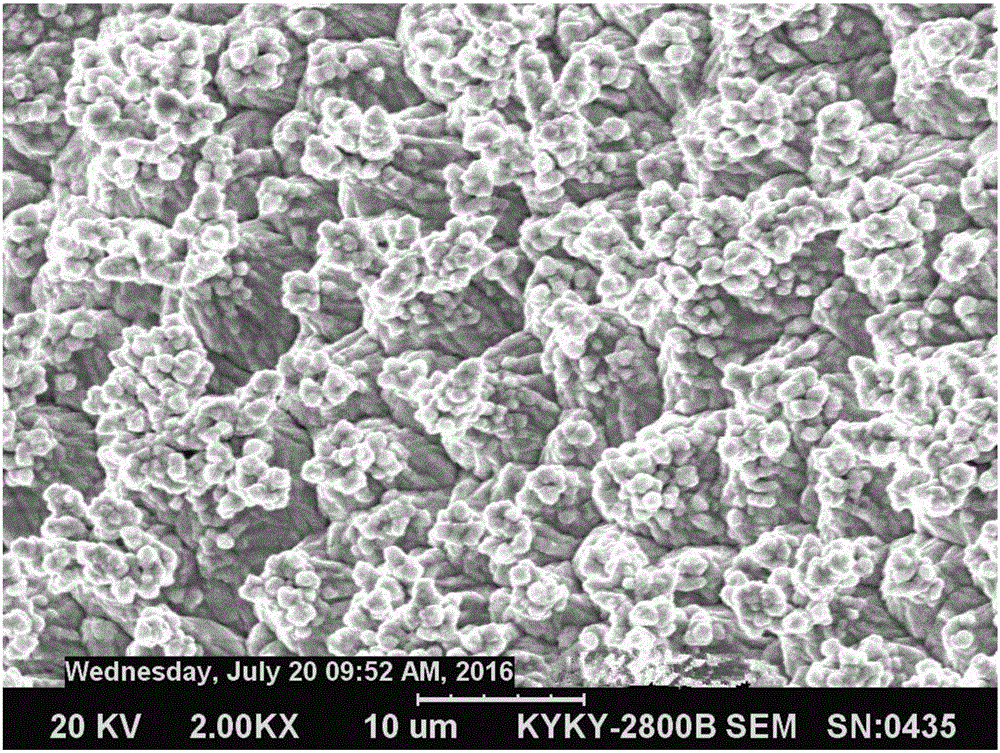

A compound additive and surface treatment technology, applied in the field of electrolytic copper foil processing, can solve the problems of edge corrosion, complex process, unenvironmental protection, etc., and achieve the effects of fine and tight crystallization, flat and uniform coating, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A surface treatment composite additive for improving the corrosion resistance of copper foil, containing: 1.2g polyethylene glycol, 0.4g cerium nitrate, 6.0g sodium dodecylbenzenesulfonate and 0.6g chitosan in every liter of the aqueous solution of the composite additive sugar.

[0024] The existing copper foil production process is used to produce 18μm copper foil for surface treatment. The copper foil surface treatment process used is: roughening-curing-galvanizing-anti-oxidation-coating silane coupling agent-drying. Use the compound additive that present embodiment makes in the galvanizing process, contain in the galvanizing solution: Zn 2+ 2-4g / L, Ni 2+ 0.3-0.9g / L, potassium pyrophosphate 200-300g / L, pH 8-10, temperature 30-40℃, current density 1.5-3A / dm 2 .

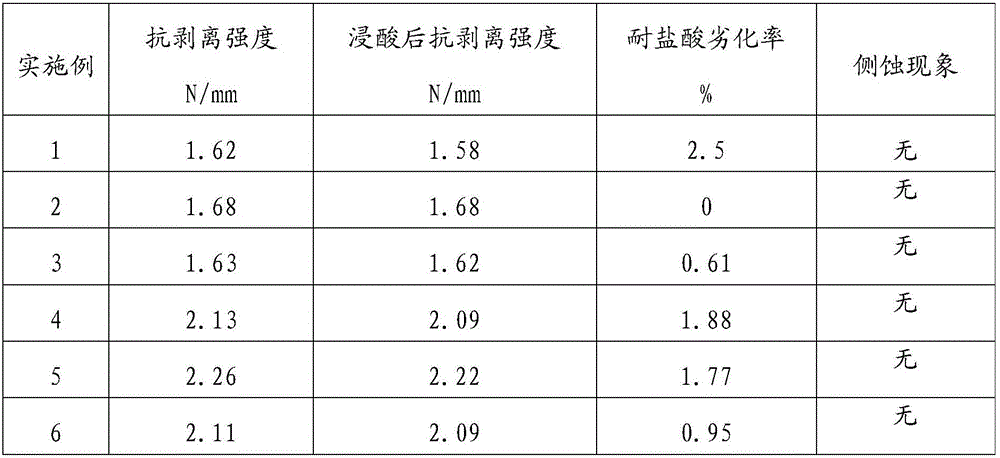

[0025] The surface-treated copper foil was pressed against the FR-4 base material to test the copper foil's anti-peel strength, hydrochloric acid degradation resistance, side corrosion and other properties....

Embodiment 2

[0027] A surface treatment composite additive for improving the corrosion resistance of copper foil, containing: 2.0g polyethylene glycol, 0.6g cerium chloride, 13g sodium dodecylbenzenesulfonate and 0.8g chitosan in every liter of the aqueous solution of the composite additive sugar.

[0028] The existing copper foil production process is used to produce 18μm copper foil for surface treatment. The copper foil surface treatment process used is: roughening-curing-galvanizing-anti-oxidation-coating silane coupling agent-drying. Use the compound additive that present embodiment makes in the galvanizing process, contain in the galvanizing solution: Zn 2+ 2-4g / L, Ni 2+ 0.3-0.9g / L, potassium pyrophosphate 200-300g / L, pH 8-10, temperature 30-40℃, current density 1.5-3A / dm 2 .

[0029] The surface-treated copper foil was pressed against the FR-4 base material to test the copper foil's anti-peel strength, hydrochloric acid degradation resistance, side corrosion and other properties....

Embodiment 3

[0031] A surface treatment composite additive for improving the corrosion resistance of copper foil, containing 4.0g of polyethylene glycol, 0.6g of lanthanum nitrate, 4.0g of sodium dodecylbenzenesulfonate and 1.0g of chitosan in each liter of the aqueous solution of the composite additive sugar.

[0032] The existing copper foil production process is used to produce 18μm copper foil for surface treatment. The copper foil surface treatment process used is: roughening-curing-galvanizing-anti-oxidation-coating silane coupling agent-drying. Use the compound additive that present embodiment makes in the galvanizing process, contain in the galvanizing solution: Zn 2+ 2-4g / L, Ni 2+ 0.3-0.9g / L, potassium pyrophosphate 200-300g / L, pH 8-10, temperature 30-40℃, current density 1.5-3A / dm 2 .

[0033] The surface-treated copper foil was pressed against the FR-4 base material to test the copper foil's anti-peel strength, hydrochloric acid degradation resistance, side corrosion and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com