Preparation method of micrometer grade NiMnCa magnetic memory alloy grain

A memory alloy, micron-scale technology is applied in the field of preparation of NiMnGa magnetic memory alloy micron-scale particles, which can solve the problems of high power consumption, uneven composition, and many defects of alloy particles, and achieves simple process, uniform composition, and preparation time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

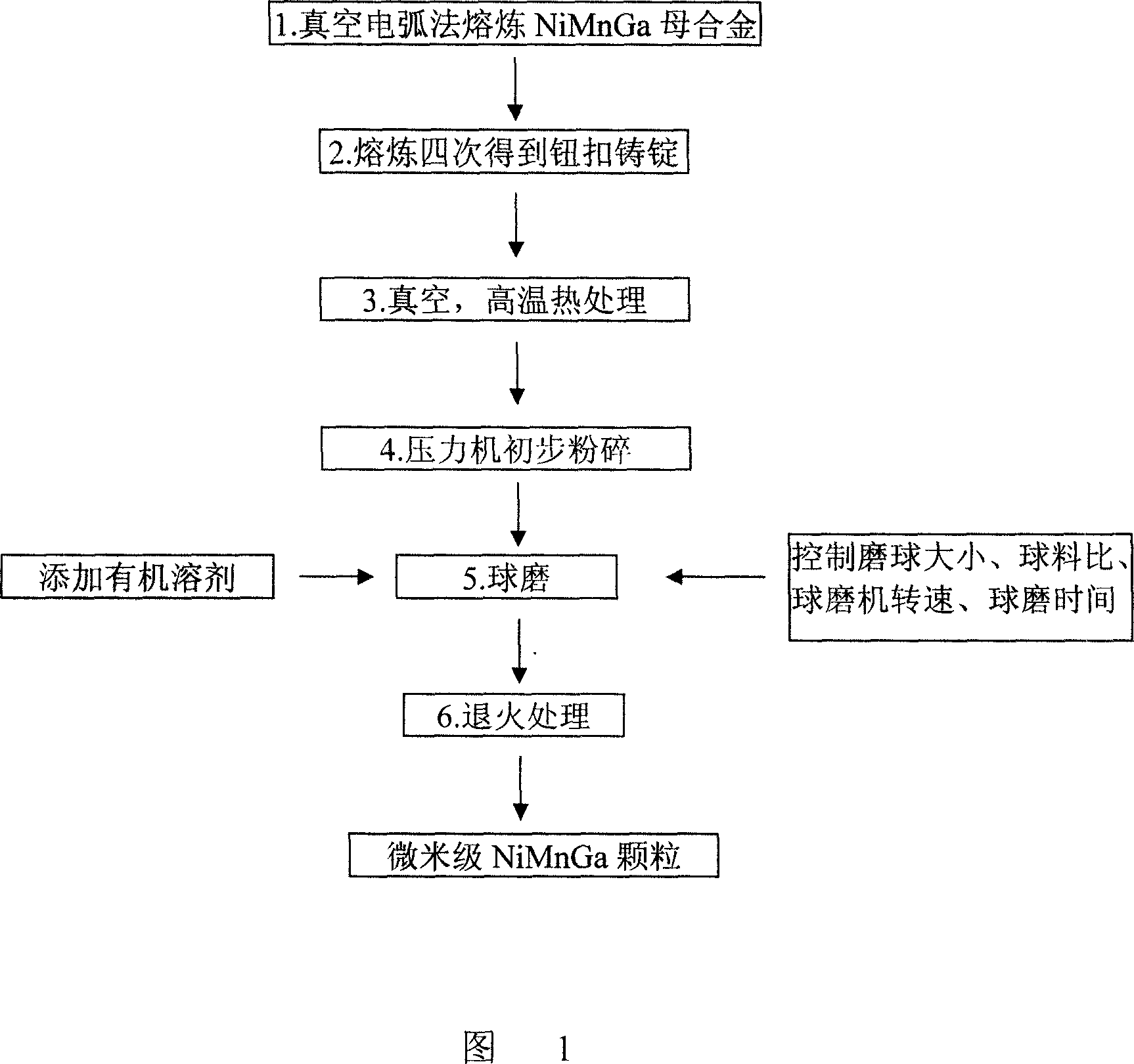

[0008] A preparation of micron Ni 52 mn 24 Ga 24 The method for magnetic memory alloy particles, its process route is:

[0009] 1. The master alloy is smelted by vacuum arc method, and the vacuum degree of the back and bottom reaches 10 -3 Pa, then filled with argon to 500Pa;

[0010] 2. Flip and smelt four times, and solidify to obtain a button-shaped ingot;

[0011] 3. Under vacuum, alloy ingots are heat-treated at 800°C, and the holding time is 24 hours;

[0012] 4. The press crushes the master alloy initially to form primary particles with a particle size of 3mm;

[0013] 5. Under the protection of argon, put the original particles into the ball milling tank, put stainless steel balls with a diameter of 18mm, the ball-to-material ratio is 10, add pure acetone, and carry out ball milling. The ball mill speed is 500 rpm, and the ball milling time is 5 hours. secondary alloy particles;

[0014] 6. Under vacuum, the secondary particles after ball milling are annealed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com