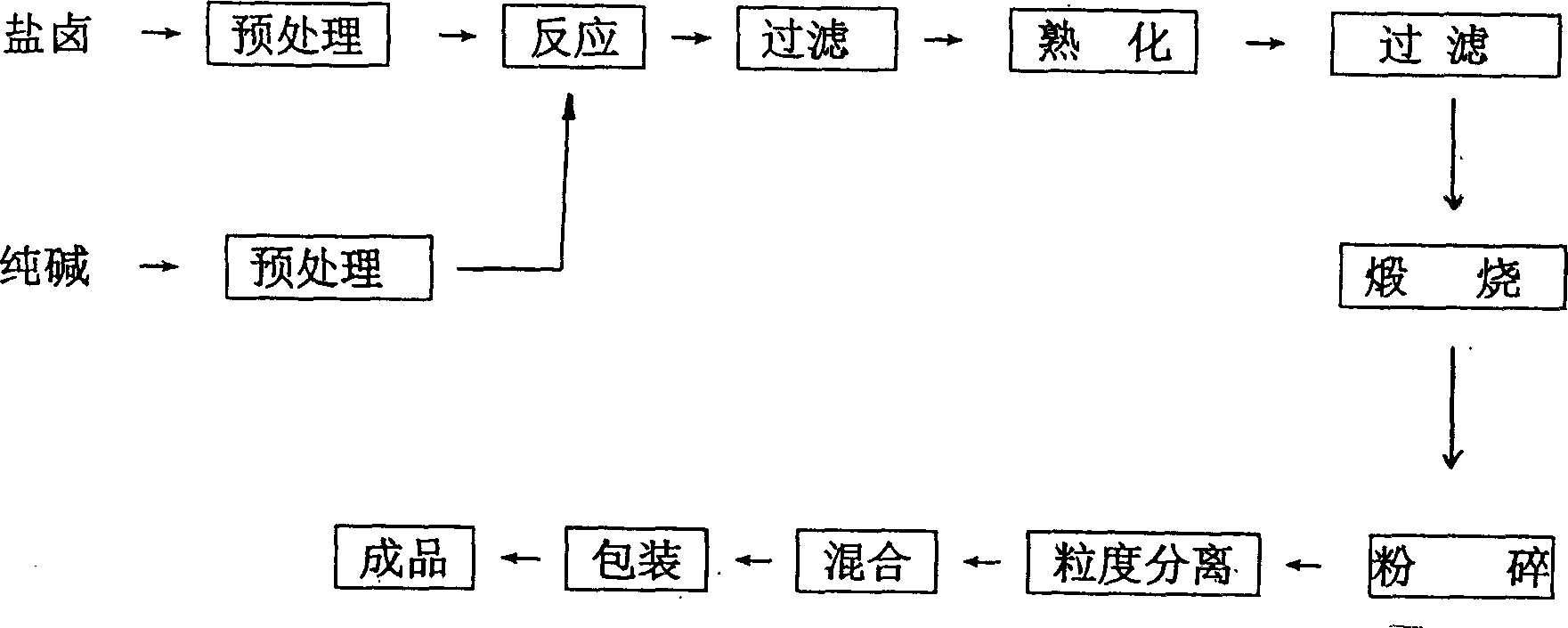

Prepn process of magnesia for silicon steel

A magnesia, silicon steel grade technology, applied in magnesia, manufacturing tools, heat treatment equipment, etc., can solve the problems of poor physical properties, long process flow, low chemical purity of final products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Dilute the bittern with water to a concentration of 1.0mol / L, heat it to a temperature of 50°C, then add the oxidant sodium hypochlorite in a stirring state, the amount of which is 3% of magnesium chloride, then add 0.2% soda ash, stir for 30 minutes, and filter to obtain Refined magnesium chloride solution. Dissolve soda ash in water, dilute to a concentration of 1.0mol / L, and heat it to a temperature of 50°C to obtain a refined sodium carbonate solution. Add a refined magnesium chloride solution with a volume of V1 and a molar concentration of 1.0 mol / L into the reactor, and add refined carbonic acid with a volume of V2 and a molar concentration of 1.0 mol / L at a rate of 800 L / min under stirring at 500 r / min. Sodium solution, the reaction time is 5min, wherein V1:V2=1.10:1.0, the reaction temperature is maintained at 65°C, and finally basic magnesium carbonate, sodium chloride and water are generated; then the stirring rate is 20r / min, and the time is 1.0h , PH = 9.5...

Embodiment 2

[0065] Dilute the bittern with water to a concentration of 2.0mol / L, heat it to a temperature of 60°C, then add the oxidant sodium hypochlorite in a stirring state, the amount of which is 3% of magnesium chloride, then add 0.2% soda ash, stir for 30 minutes, and filter to obtain Refined magnesium chloride solution. Dissolve soda ash in water, dilute to a concentration of 2.0mol / L, and heat it to a temperature of 60°C to obtain a refined sodium carbonate solution. Add a refined magnesium chloride solution with a volume of V1 and a molar concentration of 2.0 mol / L into the reactor, and add refined carbonic acid with a volume of V2 and a molar concentration of 2.0 mol / L at a rate of 150 L / min under stirring at 1000 r / min. Sodium solution, the reaction time is 15min, where V1:V2=1.2:1.0, the reaction temperature is maintained at 85°C, and finally basic magnesium carbonate, sodium chloride and water are generated; then the stirring rate is 30r / min, and the time is 2.0h , PH = 10.3...

Embodiment 3

[0067]Dilute bittern with water to a concentration of 1.3 mol / L, heat it to a temperature of 40°C, then add the oxidant sodium hypochlorite in a stirring state, the amount of which is 3% of magnesium chloride, then add 0.2% soda ash, stir for 30 minutes, and filter to obtain Refined magnesium chloride solution. Dissolve soda ash in water, dilute to a concentration of 1.3mol / L, and heat it to a temperature of 40°C to obtain a refined sodium carbonate solution. Add a refined magnesium chloride solution with a volume of V1 and a molar concentration of 1.3mol / L into the reactor, and add refined carbonic acid with a volume of V2 and a molar concentration of 1.3mol / L at a rate of 100L / min under stirring at 600r / min. Sodium solution, the reaction time is 10min, wherein V1:V2=1.05:1.0, the reaction temperature is maintained at 70°C, and finally basic magnesium carbonate, sodium chloride and water are generated; then the stirring rate is 25r / min, and the time is 1.5h , PH = 10, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com