Preparation method of Al2O3-SiC-C castable material for slag line of main trough of blast furnace

A technology of al2o3-sic-c and castables, which is applied in the field of refractory materials, can solve the problems of asynchronous service life of various parts of the main ditch, large chemical erosion and damage of castables, and affect the service life of the main ditch, so as to enhance the resistance to slag erosion Ability, improve anti-oxidation performance, improve the effect of anti-corrosion performance

Inactive Publication Date: 2009-12-02

BEIJING TONGDA REFRACTORY TECH CO LTD

View PDF0 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the industry, large and medium-sized iron trenches generally use on-site cast corundum-silicon carbide-carbon refractory materials to construct the working layer. Usually, the same material is used for different parts such as iron wires and slag wires, but the erosion and damage mechanisms of each part are different. The main factors of damage to the refractories below the iron line of the main iron ditch are molten iron erosion and erosion, while the main factors of damage to the refractory materials in the slag line area above the iron line are slag liquid erosion, oxidation, erosion, etc., because the slag liquid contains a large amount of S, Si, P, Ca, Mg and other elements have great chemical erosion damage to the castable, so that the service life of the refractory material in the slag line area is significantly lower than the service life of materials in other parts, causing the service life of each part of the main ditch to be out of sync. , affecting the overall service life of the main ditch

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

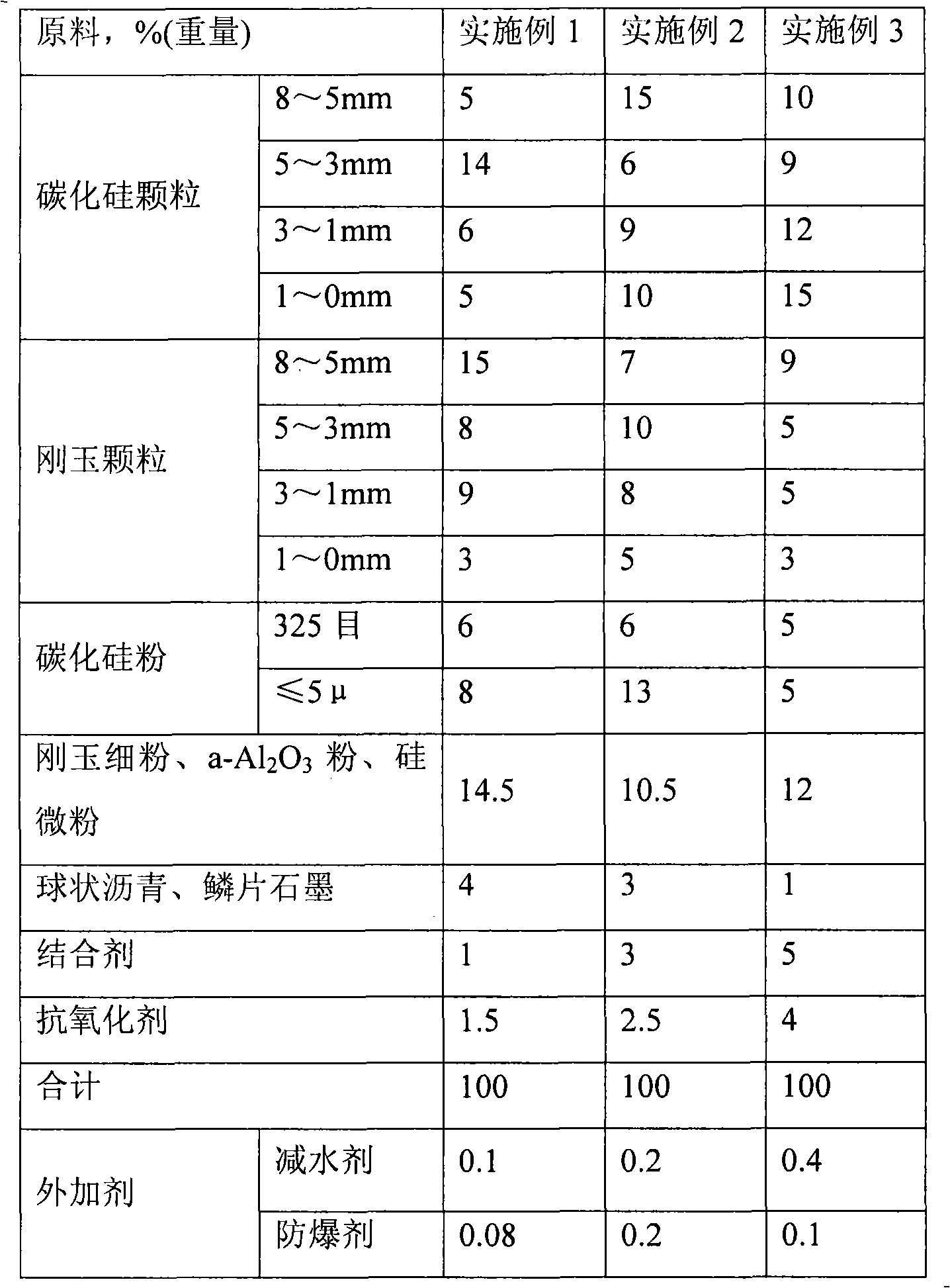

[0013] Table 1 lists three kinds of castables prepared according to the present invention, which are Example 1-Example 3 respectively.

[0014] Table 1

[0015]

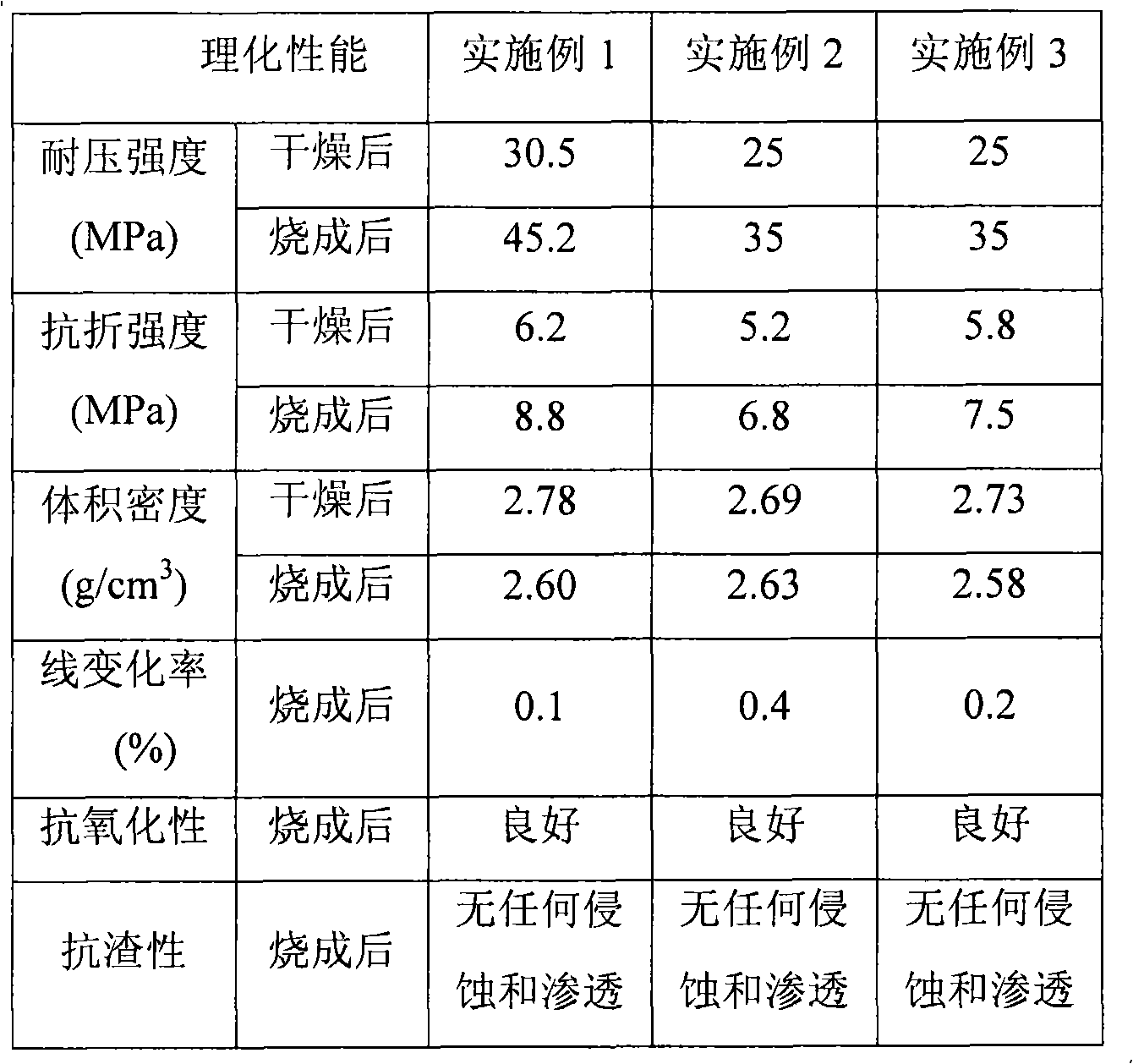

[0016] Add appropriate water to the mixture according to the above ratio, pour it into shape, and then test its performance after drying, curing, and firing. The results are shown in Table 2.

[0017] The physical and chemical properties of table 2 embodiment 1-5

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an Al2O3-SiC-C castable material for a slag line of a main trough of a large blast furnace and a preparation method thereof. The castable material comprises an aggregate, a matrix, a bonding agent, an antioxidant and an admixture; wherein, the aggregate comprises corundum grains and carborundum grains; the matrix comprises ball pitch, flake graphite, corundum fine powder, a-Al2O3 ultrafine powder, silicon powder and carborundum ultrafine powder; the bonding agent is aluminate cement; the antioxidant is a compound of aluminium powder and silicon powder; the admixture comprises a water reducing agent and a detonation suppressor. The castable material is prepared by the steps of mixing various raw materials evenly, adding water, stirring, casting molding, maintaining and drying. The castable material has strong anti-slag corrosion and anti-scour capabilities, good high temperature resistance, abrasion resistance and thermal shock resistance, slight reheating change and long service life.

Description

technical field [0001] The invention relates to a pouring material used above the slag line of the main tapping ditch of a large-scale ironmaking blast furnace, and belongs to the field of refractory materials. Background technique [0002] In recent years, with the development of blast furnaces in the direction of large-scale, automation, high efficiency, and long life, and the use of new technologies such as high wind temperature, high-pressure furnace roof, oxygen-enriched, and coal injection to strengthen smelting, the working conditions of the iron trench have become increasingly harsh. At the same time, the increase in the amount of ironing and the increase in the time for the ironing put forward new requirements for the tapping channel. [0003] At present, generally large and medium-sized blast furnaces adopt the iron storage type main iron trench, which is conducive to the separation of slag and iron, and also helps to improve the service life of the castable at the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B35/66

Inventor 冯运生李平王林俊高长贺王安杰王艳玲陈超群任颖丽

Owner BEIJING TONGDA REFRACTORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com