Free-cutting water-atomized steel powder and preparation method thereof

A steel powder and manufacturing method technology, applied in the field of powder metallurgy, can solve problems such as uneven mixing of components, easily damaged cutter heads, and poor cutting performance of sintered products, and achieve the effects of low cost, high production efficiency, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

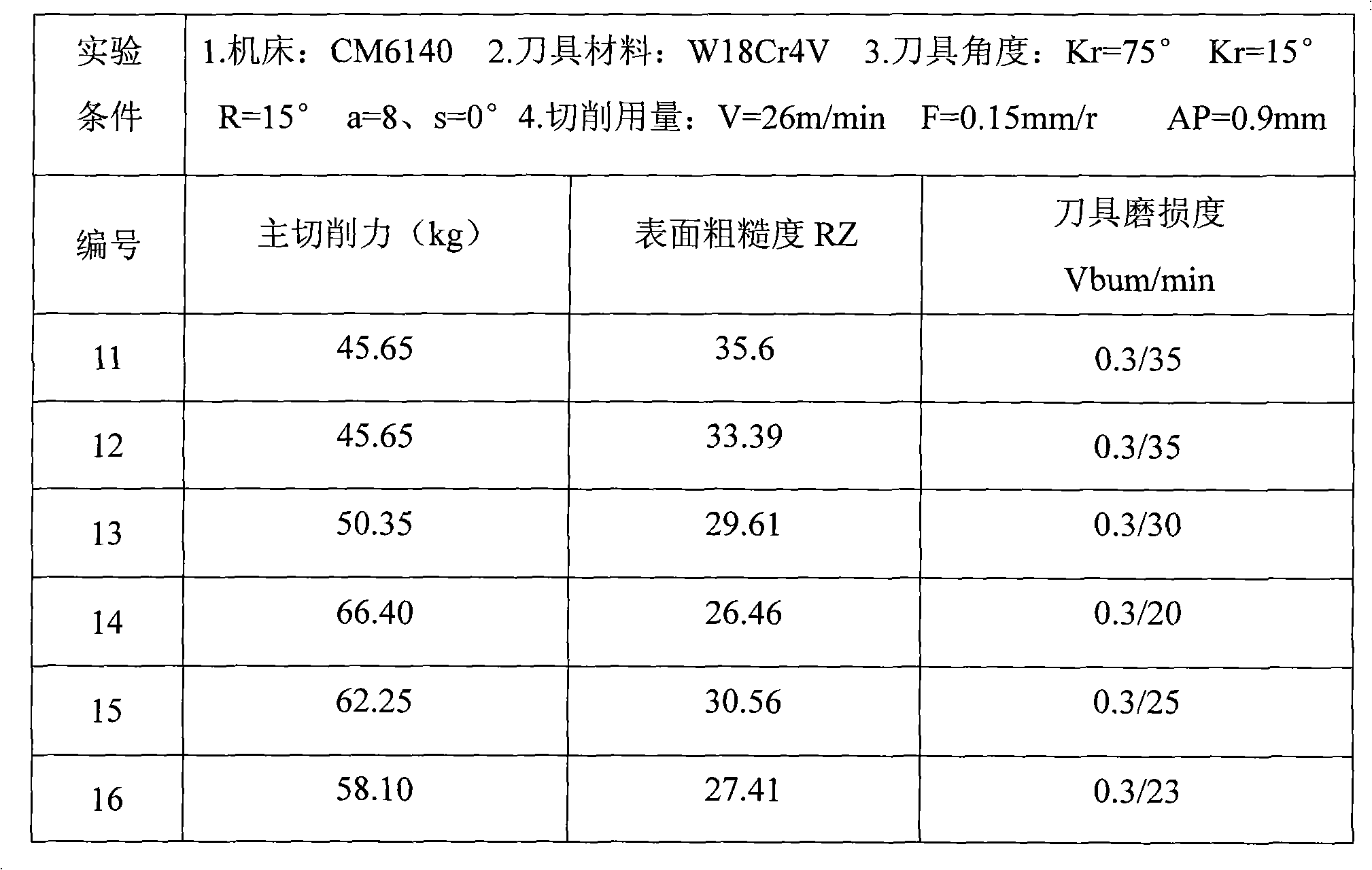

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0013] The manufacturing method of free-cutting water atomized iron and steel powder includes smelting, water atomization and reduction, and the method of adding high-sulfur ferroalloy is used to control the content of S in the iron and steel powder. The operation steps are as follows:

[0014] 1) Smelting, smelting scrap steel in an electric furnace to obtain liquid steel with uniform and stable composition and few impurities. 15kg / ton, particle size 20-80 mesh, stir until uniform.

[0015] 2) Water atomization process parameters, the tapping temperature of molten steel is 1750±10°C, the atomization start temperature is 1680±10°C, the atomization end temperature is 1650±5°C, the diameter of molten steel flow is 30-35mm, and the atomization temperature is 1680±10°C. Speed 3.1~3.8kg / s, high pressure water pressure 115±10MPA, flow rate 185±5m 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com