A method for controlling aluminum in molten steel during refining

A technology of refining process and control method, which is applied in the field of molten steel refining, and can solve problems such as difficult narrow range control of Al element in vacuum treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

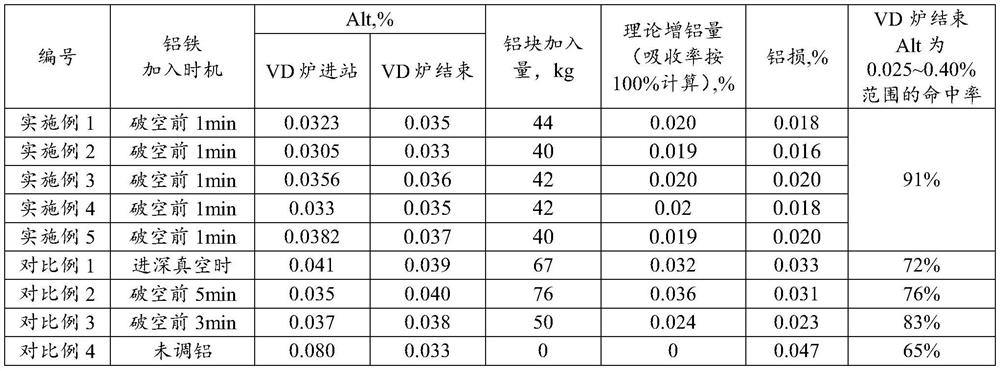

Examples

Embodiment 1

[0048] The smelted steel is Q345DH steel, which is produced by the "LF furnace-VD furnace" process route. The ladle capacity is 210t, and the VD outbound aluminum requirement is 0.02-0.060%. The total amount of slag made by LF furnace is 1000kg, the final slag ∑ (FeO+MnO) is 0.81%, and the alkalinity is 6; the aluminum content in the incoming steel of VD furnace is 0.0323%, and the free oxygen content in steel is 4ppm; VD furnace is vacuum refined The total time is 18 minutes, and the deep vacuum is maintained at 23-67Pa for 10 minutes; 3 minutes before the repressurization, the bottom blowing argon gas is adjusted from 130Nl / min to 50Nl / min; 1 minute before the repressurization, 42kg of aluminum block is added; After air-repressurization operation, add 62kg calcium wire and soft blow at the same time.

Embodiment 2

[0050] The smelted steel is E36 steel, aluminum-containing steel, which is produced by the "LF furnace-VD furnace" process route. Ladle capacity is 210t, VD outbound aluminum requirement is 0.02~0.060%. The total amount of slag made by LF furnace is 1100kg, the final slag ∑ (FeO+MnO) is 0.75%, and the alkalinity is 8; the aluminum content in the incoming steel of VD furnace is 0.0305%, and the free oxygen content in steel is 3ppm; VD furnace is vacuum refined The total time is 18 minutes, and the deep vacuum (20~67Pa) is maintained for 11 minutes; 3 minutes before the repressurization, the bottom blowing argon gas is adjusted from 180Nl / min to 30Nl / min, and after adding 40kg aluminum block, it is kept for 1 minute, and the repressurization is performed for 1 minute. Press operation; add 65kg calcium wire for calcium treatment, and soft blow at the same time.

Embodiment 3

[0052] The smelted steel is 45Mn2V steel, which is produced by the "LF furnace-VD furnace" process route. Ladle capacity is 210t, VD outbound aluminum requirement is 0.02-0.060%. The total amount of slag produced by LF furnace is 1150kg, the final slag ∑ (FeO+MnO) is 0.91%, and the alkalinity is 7; The total refining time is 16 minutes, and the deep vacuum (20-67Pa) is kept for 10 minutes; 3 minutes before the repressurization, the bottom blowing argon gas is adjusted from 150Nl / min to 50Nl / min, and after adding 42kg of aluminum block, it is kept for 1 minute, and the vacuum is broken. Repressurization operation; adding 50kg calcium wire for calcium treatment, and soft blowing at the same time, the flow rate of soft blowing is 45Nl / min, take the finished steel sample for analysis, the aluminum content in the steel is 0.0346%, which meets the aluminum content requirements of smelting steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com