Double-liquid composite casting protective agent

A composite casting and protective agent technology, applied in the field of casting, can solve the problems of relatively large fluctuations in the process parameters of the double-liquid composite casting, and the low pass rate of the double-liquid composite product, so as to achieve guaranteed performance, strong bonding force, and less double-liquid fusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Double-liquid composite casting of a bimetallic hammer head.

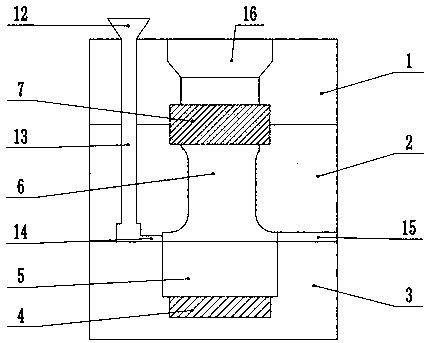

[0018] The bimetallic hammer head is composed of high chromium cast iron hammer end and carbon steel or low alloy steel hammer handle to meet the unity of wear resistance and high toughness. attached figure 1 It is a schematic diagram of the pouring system of a bimetallic hammer head. The molding sand box includes an upper box 1, a middle box 2 and a lower box 3. The lower part of the cavity is the hammer end cavity 5, and the upper part is the hammer handle cavity 6. At the bottom of the hammer end cavity 5 A cold iron I4 is installed, and a sand core 7 forming a hammer head installation hole is placed in the hammer handle cavity 6 .

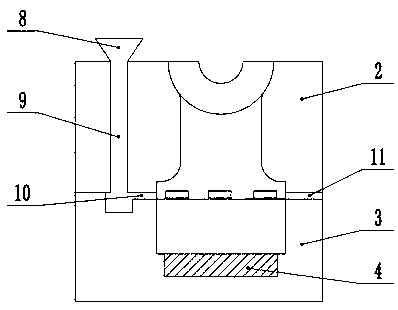

[0019] Before pouring the molten metal of high chromium cast iron at the hammer end, position and assemble the middle box 2 and the lower box 3, as attached figure 2 As shown, the high chromium cast iron sprue cup 8, the high chromium cast iron sprue I9, the hig...

Embodiment 2

[0028] Example 2: bimetallic wear plate.

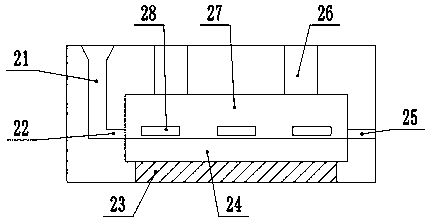

[0029] The bimetal wear-resistant plate is composed of high-chromium cast iron and carbon steel or low-alloy steel. The wear-resistant layer is the working layer. The material is high-chromium cast iron, and the carbon steel or low-alloy steel layer is the base layer. attached image 3 And attached Figure 4 It is a schematic diagram of the pouring system for bimetallic wear-resistant plates. After the sand boxes are combined, a plate-type cavity is formed. The upper part is a carbon steel cavity 27, and the lower part is a wear-resistant cavity 24. At the bottom of the wear-resistant cavity 24, a cold iron II 23 is designed. The high chromium cast iron pouring system includes a high chromium cast iron sprue II21, a high chromium cast iron inner runner II22 and a high chromium cast iron overflow outlet II25. Carbon steel or low alloy steel gating system includes carbon steel sprue II29, carbon steel inner runner II30, carbon steel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com