Anti-electromagnetic interference type communication power cable

An anti-electromagnetic interference, optical fiber composite cable technology, applied in power cables, power cables with shielding/conducting layers, power cables including optical transmission components, etc., can solve the problems of poor anti-electromagnetic interference of optical fibers, etc. Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

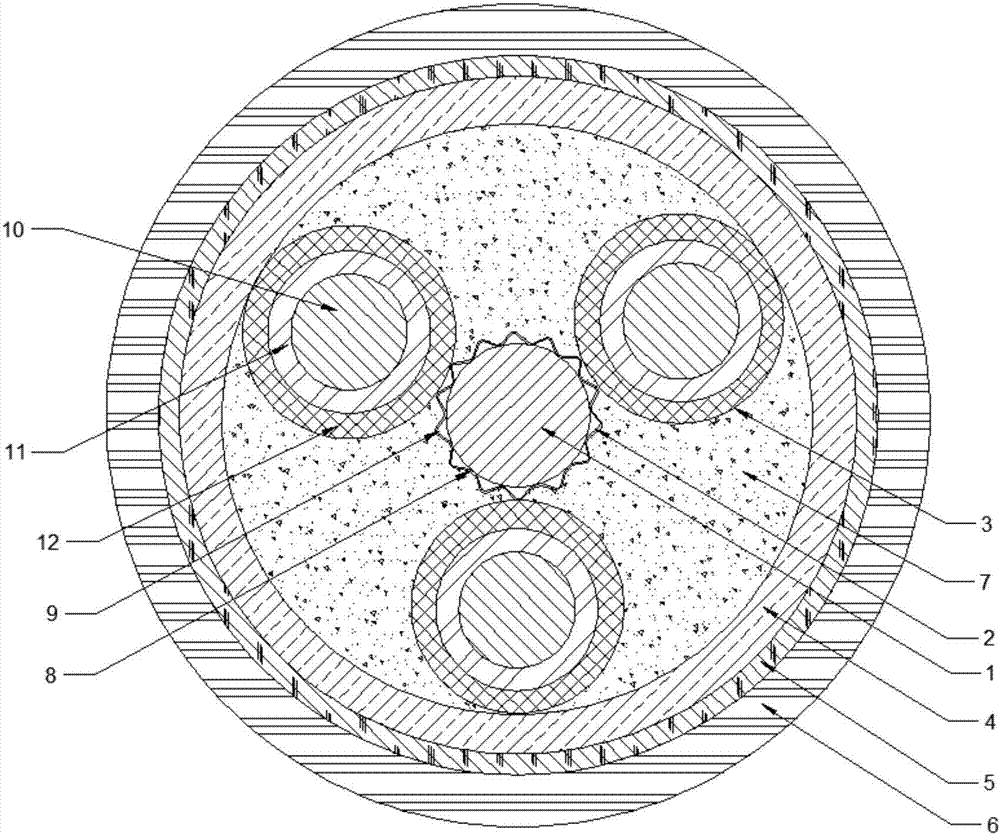

[0024] In order to improve the structural stability of the aluminum alloy wire cores 3 , the aluminum alloy wire cores 3 are evenly distributed outside the bent tube 2 . In this embodiment, the aluminum alloy wire core 3 includes an aluminum alloy inner core 10 , a copper cladding layer 11 , and a halogen-free flame-retardant polyolefin layer 12 arranged sequentially from the inside to the outside. Because of the skin effect of the conductor, the current mainly passes through the surface, so the copper alloy of the same specification has a resistance value close to that of copper. Under the same resistance, its AC resistance and current carrying capacity are better than copper, so the line loss is also lower than copper; The copper-clad aluminum alloy wire core 3 of the present invention has the same solderability as copper and the same contact resistance as copper; compared with the existing copper wire core material, the present invention has light weight (about 40% of copper...

Embodiment 2

[0026] On the basis of Example 12, the outer protective layer 6 is a halogen-free flame-retardant polyolefin protective layer. The material of the filler 7 is ceramic polyolefin. The material of the bending tube 2 is bending resistant plastic. Since the present invention is not easy to produce toxic smoke when encountering fire, the safety of the overall structure is better, and the ceramic polyolefin with flame-retardant and heat insulation is used to fill the gaps between the multi-strand cables, so that the overall structure will be produced when encountering fire. The armor body and the adjacent multi-strand cables do not affect each other, making it safer. Because the overall structure has better flame retardancy, the corresponding fire performance is stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com