Binary adjustable pre-converting method for preparing sulfuric acid from high concentration sulfur dioxide flue gas

A technology of sulfur dioxide and pre-conversion, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve the problems of huge equipment, increased investment and operating costs, and unfavorable comprehensive heat recovery, etc., to reduce operating costs and reduce equipment investment Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

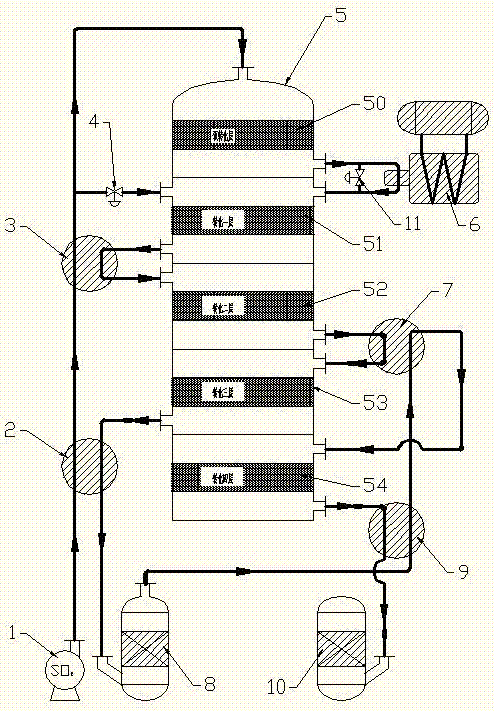

Embodiment 1

[0028] A gold smelting enterprise in Henan, the smelting flue gas of a gold smelting project (when the smelting furnace is fully loaded, working condition 1), contains SO 2 The volume concentration is 16.5%, containing O 2 The volume concentration is 13%, and the flue gas flow rate is 100000Nm 3 / h. The process of adopting the pre-conversion sulfuric acid method of the present invention is as follows: from the outside world containing SO 2 The flue gas with a concentration of 16.5% and a temperature of 80°C is passed through SO 2 After the blower 1 is pressurized, it enters the initial cold and hot heat exchanger 2, and performs heat exchange with the hot flue gas at the outlet of the traditional catalyst three-layer 53. The temperature rises to 200°C, and the SO after heat exchange 2 The flue gas enters the initial thermal heat exchanger 3 again, and exchanges heat with the hot flue gas at the exit of the first layer 51 of the traditional catalyst, and the SO after two heat...

Embodiment 2

[0030] A gold smelting enterprise in Henan, the smelting flue gas of the gold smelting project (when part of the smelting furnace is running, working condition 2), SO 2 The volume concentration is 13%, O 2 The volume concentration is 13.5%, and the flue gas flow rate is 110000Nm 3 / h. The process of adopting the pre-conversion sulfuric acid method of the present invention is as follows: from the outside world containing SO 2 The flue gas with a concentration of 13% and a temperature of 80 ° C is passed through SO 2 After the blower 1 is pressurized, it enters the initial cold and hot heat exchanger 2, and performs heat exchange with the hot flue gas at the outlet of the traditional catalyst three-layer 53. The temperature rises to 260°C, and the SO after heat exchange 2 The flue gas then enters the initial thermal heat exchanger 3, and exchanges heat with the hot flue gas at the outlet 51 of the traditional catalyst layer. After two heat exchanges, the temperature of the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com