Method for economically recycling sulphur dioxide from low-concentration or non-continuity flue gas to produce sulphuric acid

A sulfur dioxide, continuous technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of high energy consumption, high operating cost, large steam consumption, etc., to reduce energy consumption, promote value, and recover sulfur resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

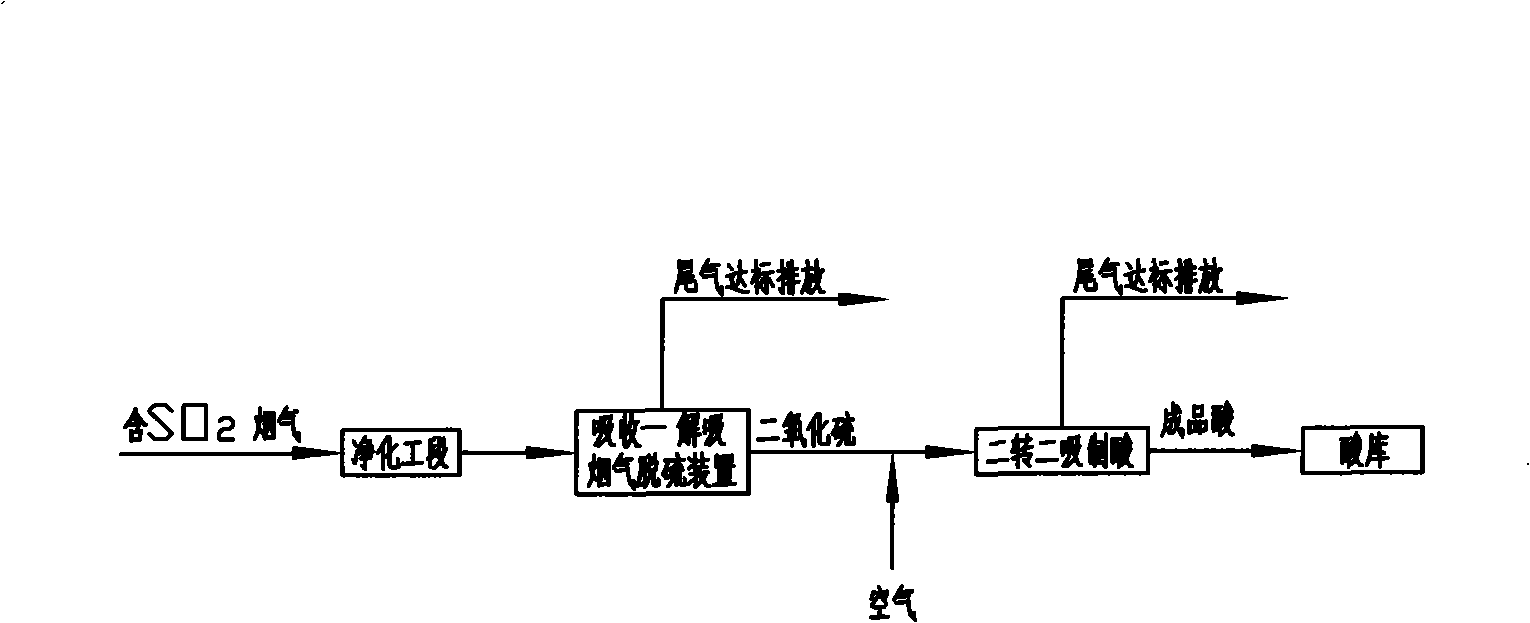

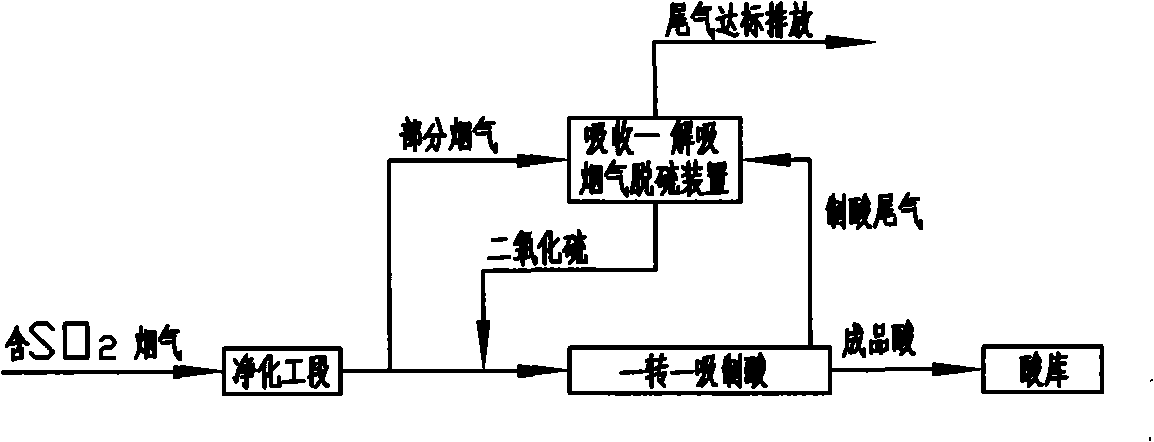

[0010] low concentration of SO 2 Or the non-continuous smelting flue gas is divided into two paths after purification, dust removal, impurity removal, cooling, and acid mist removal, one of which is controlled by a fan through a regulating valve to control the gas volume of the desulfurization section in proportion, and the flue gas produced by absorption and desorption Very high purity SO 2 The gas is evenly mixed into another flue gas that has not been desulfurized, and the mixed flue gas SO 2 When the concentration is increased to more than 5%, it enters the acid production section with one rotation and one suction, and the tail gas after acid production enters the desulfurization section again after desulfurization, SO 2 The content is far below the emission standard and then discharged directly. In addition, there is a waste heat boiler in the conversion section to recover excess heat to produce steam. Turn the smelting flue gas that cannot meet the requirements of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com