Powder slurry delivering device

A slurry conveying and slurry technology, applied in the field of powder slurry conveying device, can solve the problems of easy contamination of powder slurry, affecting product quality, low work efficiency, etc., saving labor costs, time and reliability of the handling process High, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

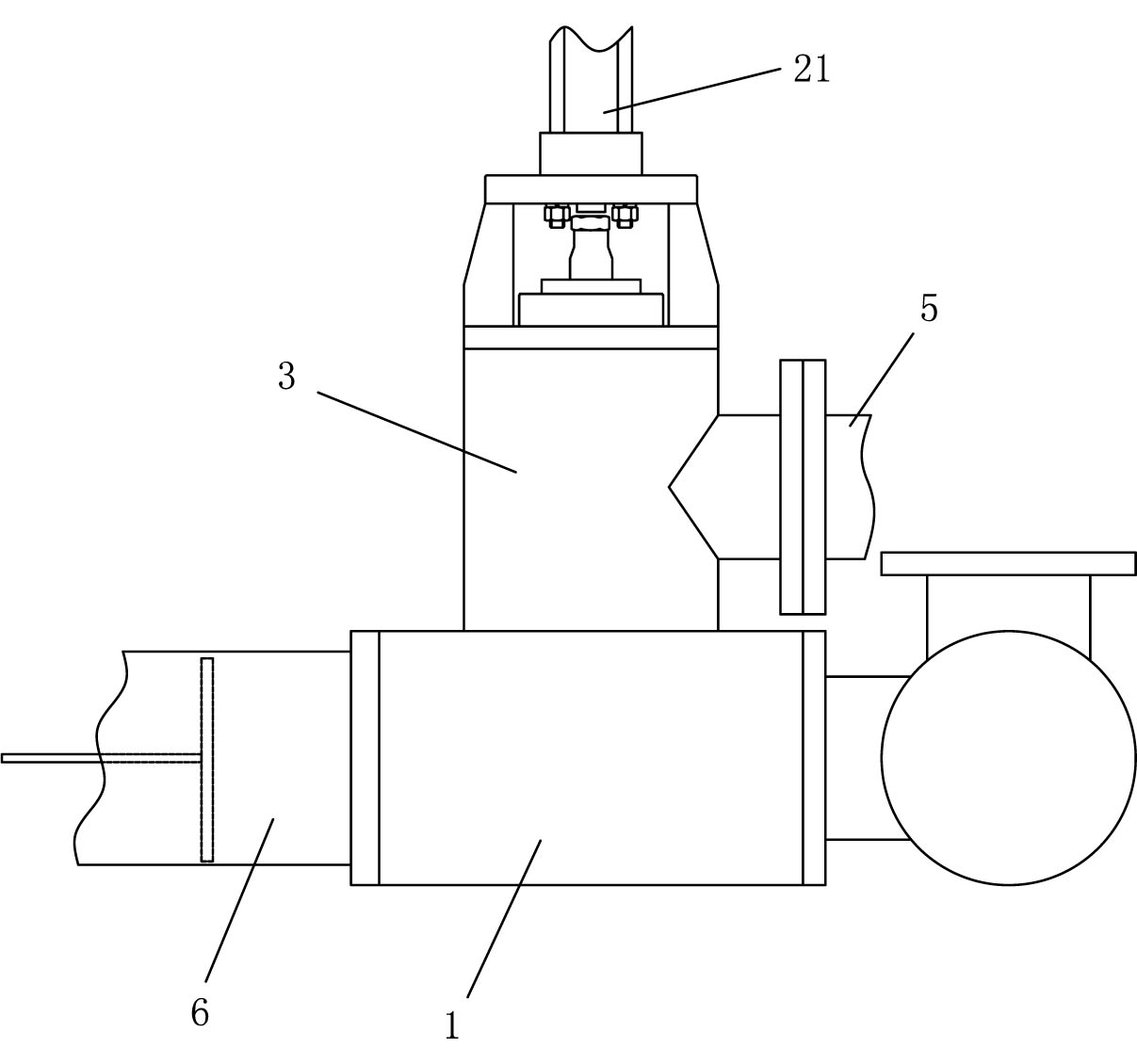

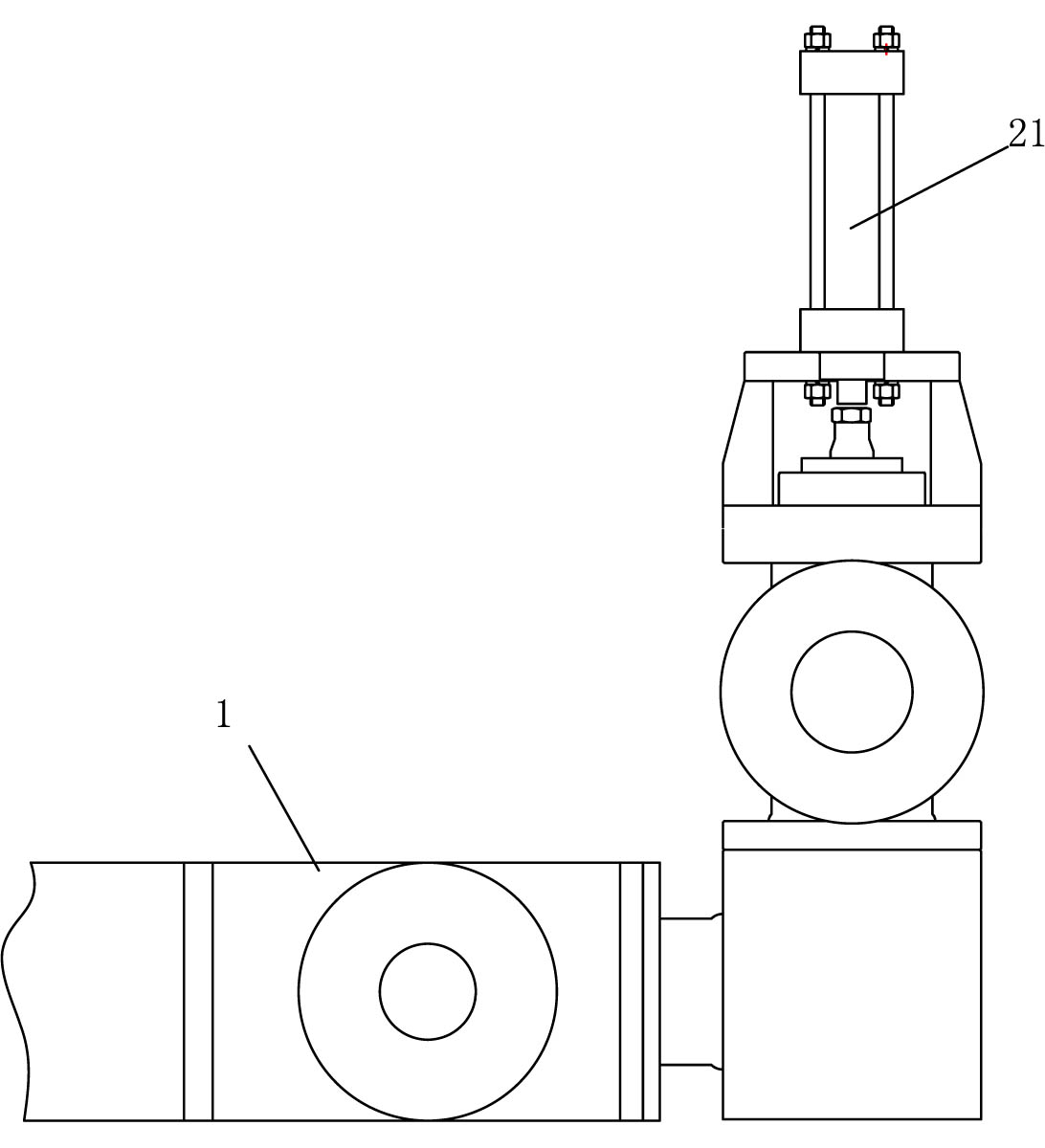

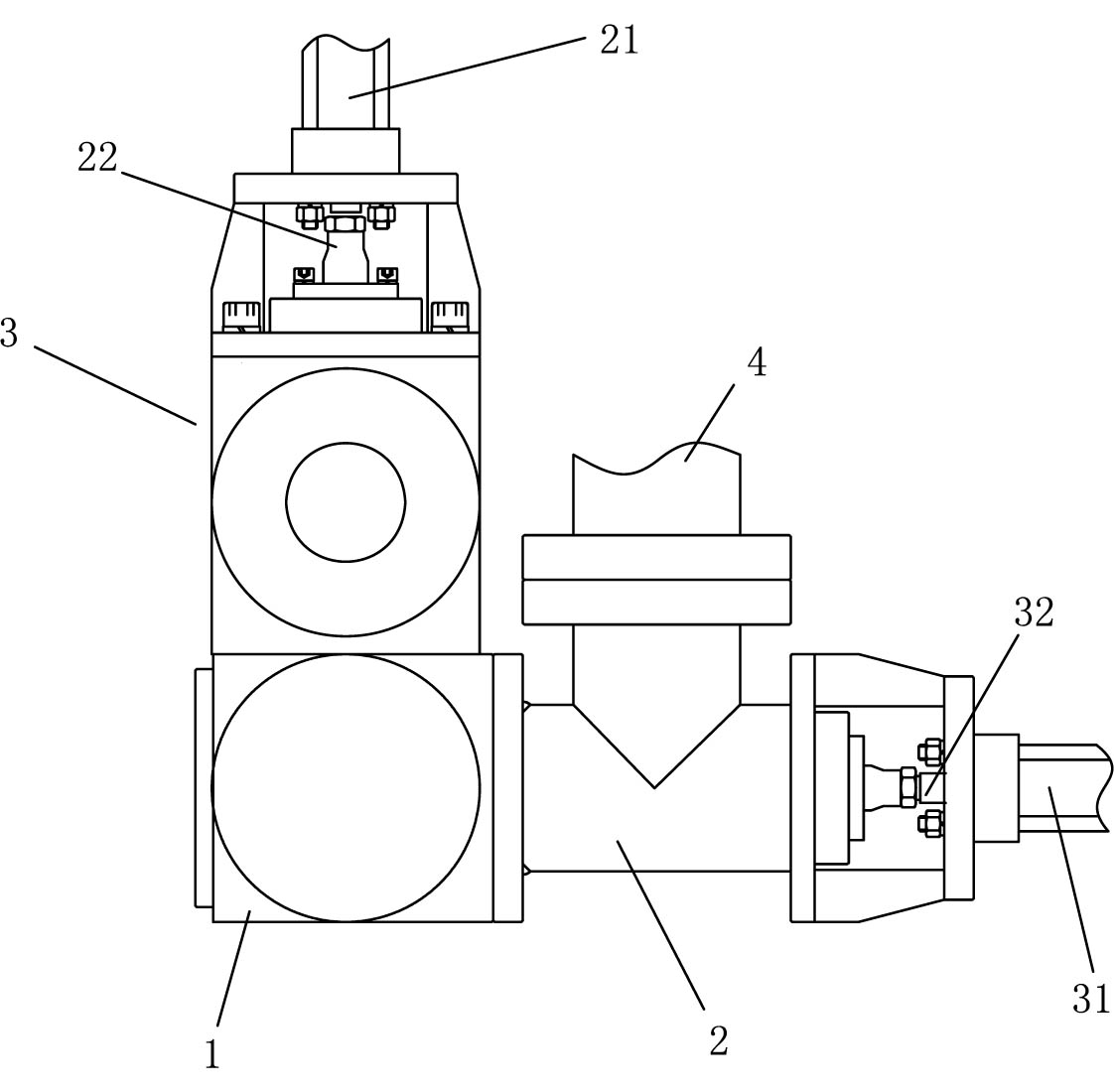

[0019] refer to Figure 1 to Figure 5 As shown, a powder slurry conveying device includes a slurry chamber 1, a feed lock valve 2 is provided at the entrance of the slurry chamber 1, a discharge lock valve 3 is provided at the outlet of the slurry chamber 1, and a feed lock valve 2 It is connected to the feed pipe 4, the discharge lock valve 3 is connected to the discharge pipe 5, and the slurry chamber 1 is also connected to a delivery pump 6. Preferably, the delivery pump 6 is a reciprocating piston pump.

[0020] When working, under the action of the delivery pump 6, the slurry from the feed pipe 4 is sucked into the slurry chamber 1 through the feed lock valve 2, and then output to the discharge pipe 5 through the discharge lock valve 3, and at the same time Multiple slurry production equipment supply materials. In actual application, in order to make the powder slurry conveying device operate uninterruptedly, a storage bin is usually provided at the end of the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com