Method for preparing gallic acid

A gallic acid and gallic acid technology, applied in the field of preparation of gallic acid, can solve the problems of unsafe hydrolysis, easy volatilization of ammonia water, and insufficient yield, and achieve the effects of easy treatment, low pollution of "three wastes" and high yield of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

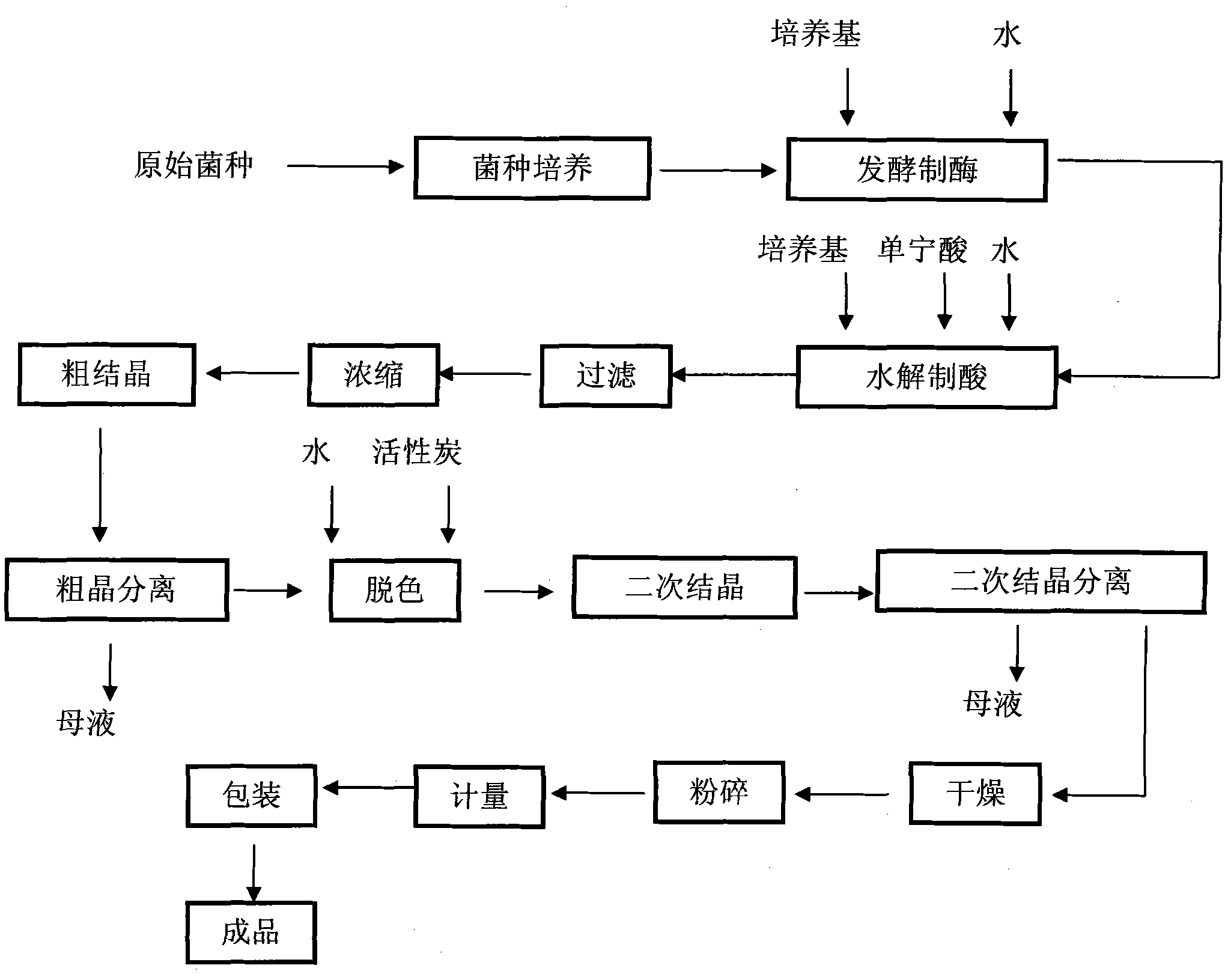

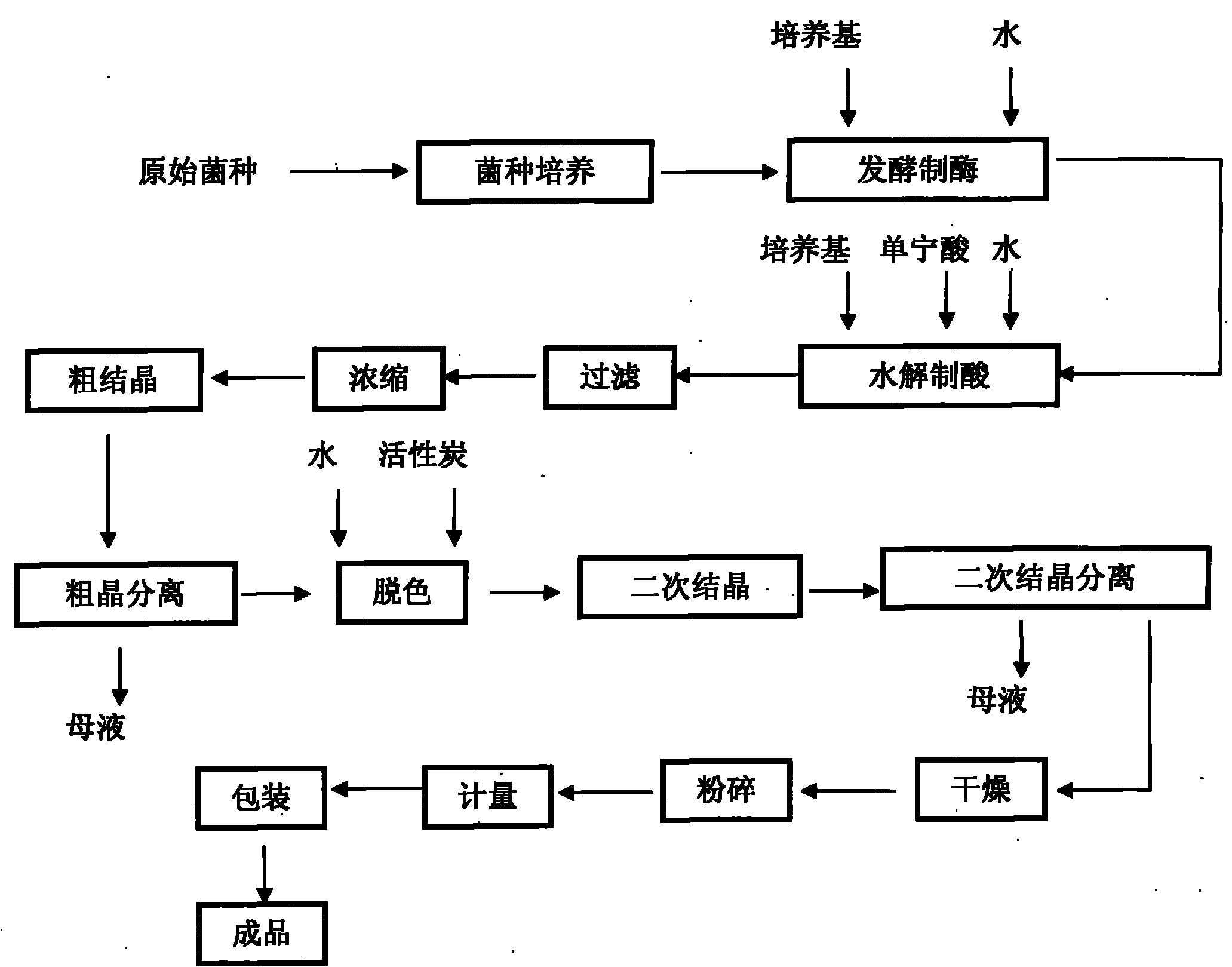

Image

Examples

Embodiment 1

[0014] Prepare culture medium according to the following components (g / l)

[0015] (NH 4 ) 2 SO 4 2

[0016] K H 2 PO 4 2

[0017] MGSO 4 7H 2 O 1

[0018] Zn 4 0.6

[0019] yeast paste 1

[0020] Sucrose 15

[0021] Tannic acid 100

[0022] Divide the prepared medium into several 1000ml Erlenmeyer flasks for sterilization. In order to avoid high-temperature oxidation of tannins, tannic acid was added after sterilization to adjust the initial pH value of the solution to 4.0 with 10mol / L NaOH; then immediately inoculated with Aspergillus niger NO.316, and placed on a ZHWY-2102C constant temperature oscillator for reaction. Set the temperature at 23-38°C, adjust the rotation speed at 120-128r / min, adjust it several times with 10mol / L NaOH, keep the pH value of the reaction solution at about 3.0-5.5, react continuously for 30h, and measure the enzyme activity or tannin The acid residue changes slowly, that is, it is used to make acid.

Embodiment 2

[0024] Prepare medium (g / L) according to the following components:

[0025] NH 4 cl 2

[0026] K H 2 PO 4 2

[0027] MgSO 4 7H 2 O 1

[0028] ZnSO 4 0.6

[0029] yeast paste 1

[0030] Glucose 15

[0031] Tannic acid 100

[0032] Vitamin B complex 8mg / L

[0033] The prepared medium was divided into several 1000ml Erlenmeyer flasks, and tannin was added after sterilization. Remaining steps are carried out according to enzyme production embodiment 1.

[0034] Acid-making embodiment:

[0035] Prepare medium (g / L) according to the following components:

[0036] (NH 4 ) 2 SO 4 2

[0037] K H 2 PO 4 2

[0038] MgSO 4 7H 2 O 1

[0039] ZnSO 4 0.6

[0040] yeast paste 1

[0041] Put the prepared medium into the fermenter equipped with a semi-automatic feeding alkali device and an external pH meter and dissolved oxygen meter, and sterilize.

[0042] Tannic acid is added to dissolve, so that the concentration of tannin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com