Forced circulation pickling method of copper and copper alloy tubes, rods and wires

A technology of forced circulation and copper alloy, which is applied in the field of forced circulation pickling of rods and wires, copper and copper alloy pipes, which can solve the problems of corrosion of production equipment and workshops, damage to the health of personnel, and pollution of workshop air, etc., to achieve Reduce processing capacity, save equipment investment, and achieve high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

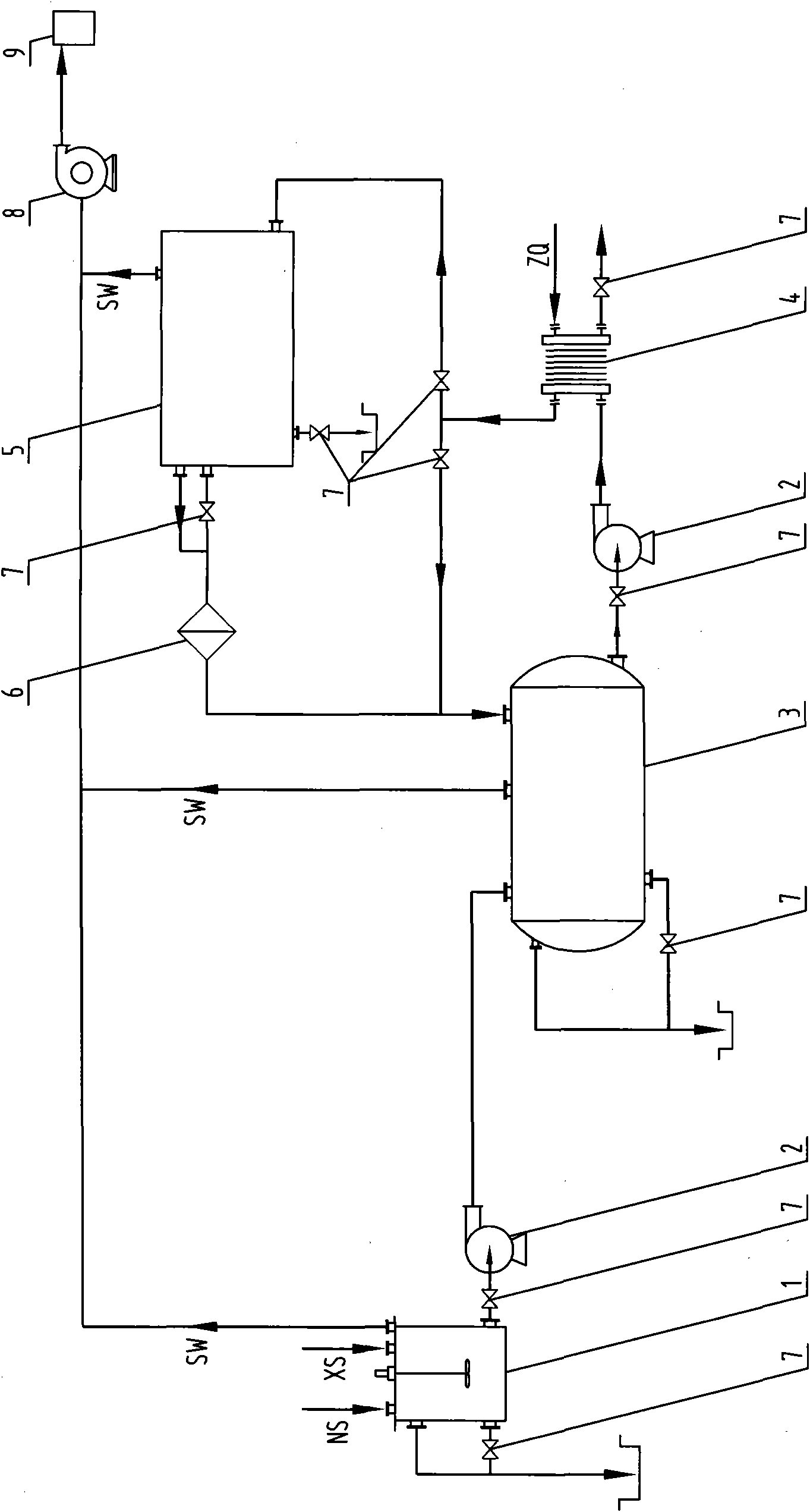

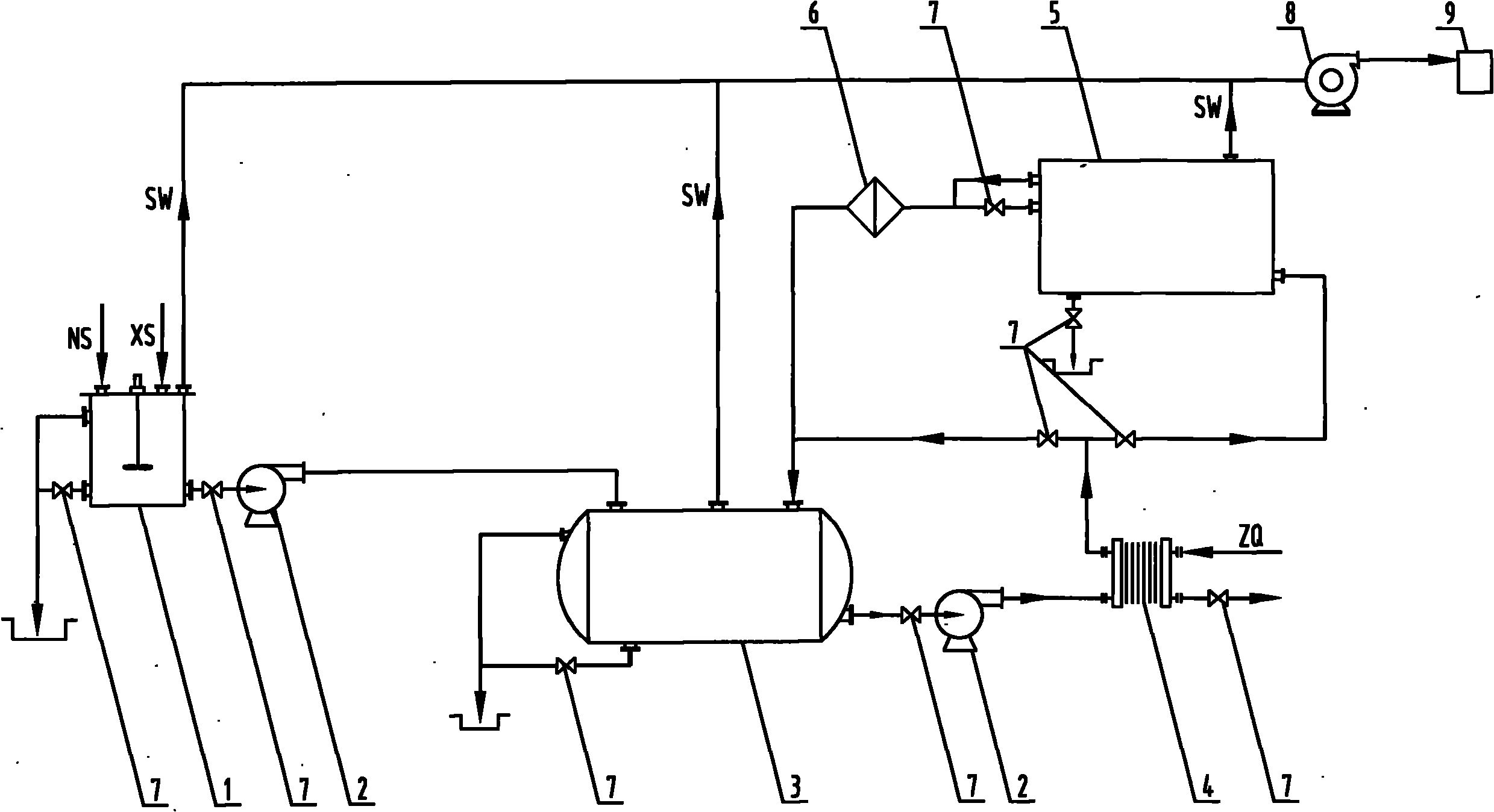

[0011] A pickling process for copper and copper alloy tubes, rods and wires, the process consists of acid preparation, cycle heating, cycle pickling and other processes, the equipment includes acid distribution tank 1, circulation tank 3, pickling tank 5, circulation pump 2, Heat exchanger 4, switching valve 7. The acid preparation is carried out in the closed acid preparation tank 1, which is configured in proportion and stirred evenly before being transported to the circulation tank 3. Acid dispensing is an intermittent operation, and multiple sets of cyclic pickling systems can share one acid dispensing tank 1 . The circulation tank 3 forms a small circulation loop with the heat exchanger 4 through the pipeline and the switching valve 7 to realize circulating heating; the circulation tank 3 forms a large circulation loop with the heat exchanger 4, the pickling tank 5 and the filter 6 through the pipeline and the switching valve 7 , realize cyclic pickling. The heating of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com