High-titanium type blast furnace slag concrete hollow brick

A high-titanium type and concrete technology, which is applied in the field of concrete to achieve good economic and social benefits, good thermal performance and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

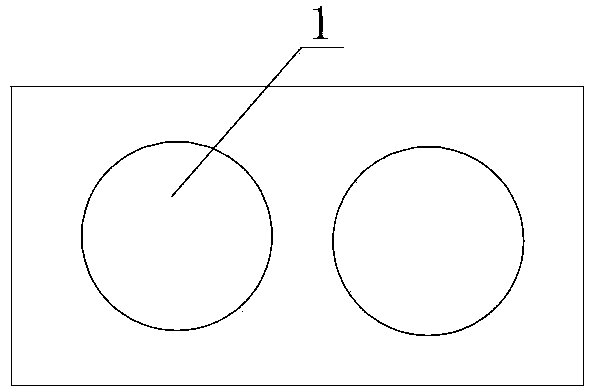

[0027] Mix cement, high-titanium blast furnace slag, and high-titanium blast furnace slag sand with different particle sizes according to the ratio in Table 1, and then add water to mix to form concrete slurry, and then use a mold to cast a cuboid shape. The size length×width×height is 390mm×190mm×190mm; one of the cuboid-shaped surfaces with length×width 390mm×190mm and the opposite surface are provided with two through holes 1 through hollow bricks, and the diameter of the through holes 1 140mm; the distance between the axes of the two through holes 1 is 190mm, and the two through holes 1 are located in the middle of the cuboid shape; after pouring, the hollow brick with excellent thermal and mechanical properties can be obtained after conventional maintenance. The results are shown in Table 1.

[0028] Table 1 Proportion and test results of MU10 high-titanium blast furnace slag air bricklaying

[0029]

[0030] According to the experiment, it can be obtained that the st...

Embodiment 2

[0032] The ratio of raw materials in embodiment two is carried out according to the ratio of the fifth group of experiments in embodiment one, and then cast into a cuboid shape with a mold. A surface of 390mm×190mm is provided with several through-holes 1 through the hollow brick between the opposite surface. The through-holes 1 are located in the middle of the rectangular parallelepiped, see Table 2.

[0033] Table 2 Hollow bricks with different shapes and test results

[0034]

[0035] It can be obtained from the test that the design of the through hole of the present invention or the shape of the hollow brick of the present invention have the best strength and thermal performance simultaneously, and changing the diameter and quantity of the through hole 1 will affect its strength and thermal performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com