Interface agent, as well as preparation method and application thereof

A technology of interface agent and initiator, which is applied in the field of interface agent, interface agent for thermal insulation composite mold-free external template system and its preparation, can solve the problems of strength decrease, interface agent poor bonding performance, falling off, etc., and achieve tensile strength Excellent tensile strength, improved application durability, and enhanced bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

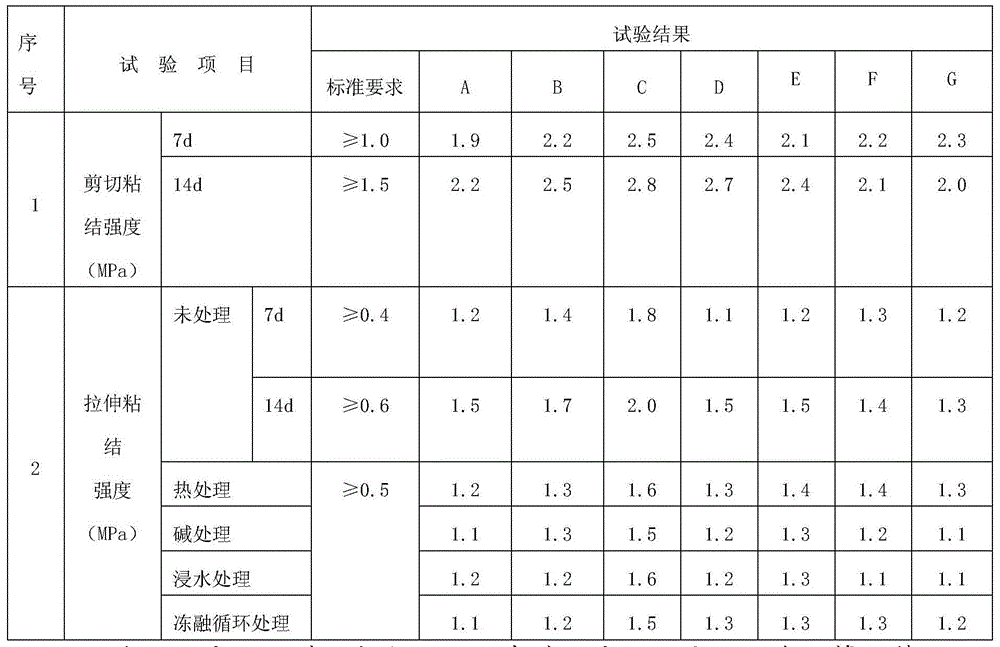

Examples

Embodiment 1

[0028] Weigh 1.2g octylphenol polyoxyethylene ether (OP-10) and 2.4g sodium dodecylbenzenesulfonate (DBS), and mix the two to obtain 3.6g of composite emulsifier, add 3.6g of composite emulsifier into 101.7g of water, stirred and dissolved to obtain a composite emulsifier solution. Get 1 / 2nd compound emulsifier solution and join in the 250ml four-neck flask, set aside. Take by weighing 25.5g n-butyl acrylate, 24.6g styrene, 4.5g propylene glycol, 30.6g methyl methacrylate and 3g acrylic acid mix and obtain mixed monomer, 12g epoxy resin E44 (WSR6101, purchased from Nantong Xingchen Synthetic Materials Co., Ltd.) was dissolved in the mixed monomers, added to a four-necked flask with a built-in complex emulsifier solution, and stirred at a high speed of 1000r / min for 1h to obtain a pre-emulsion. Take one-tenth of the pre-emulsion and the remaining half of the composite emulsifier emulsion and mix them into another four-necked flask, and add 0.9g of sodium bicarbonate to the fou...

Embodiment 2

[0031] Weigh 2.2g octylphenol polyoxyethylene ether (OP-10) and 2.0g sodium dodecylbenzenesulfonate (DBS), and mix the two to obtain 4.2g of composite emulsifier, add 4.2g of composite emulsifier into 105g of water, stirred and dissolved to obtain a composite emulsifier solution. Get 1 / 2nd compound emulsifier solution and join in the 250ml four-neck flask, set aside. Take by weighing 15g n-butyl acrylate, 21g styrene, 3g propylene glycol, 27g methyl methacrylate and 3.6g acrylic acid and mix to obtain mixed monomer, 24g epoxy resin E44 (WSR6101, purchased from Nantong Xingchen Synthetic Materials Co., Ltd.) After being dissolved in the mixed monomer, it was added to a four-neck flask with a built-in complex emulsifier solution, and stirred at a high speed of 1200r / min for 30min to obtain a pre-emulsion. Take one-tenth of the pre-emulsion and the remaining half of the composite emulsifier emulsion and mix them into another four-necked flask, and add 0.6g of sodium bicarbonate ...

Embodiment 3

[0034] Take by weighing 4.8g octylphenol polyoxyethylene ether (OP-10) and 3.2g sodium dodecylbenzenesulfonate (DBS), and the two are mixed to obtain 8g of composite emulsifier, and 8g of composite emulsifier is added to 280g water, stirred and dissolved to obtain a compound emulsifier solution. Get 1 / 2 compound emulsifier solution and join in the four-necked flask, set aside. Take by weighing 56g n-butyl acrylate, 52g styrene, 7.2g propylene glycol, 64g methyl methacrylate and 5.2g acrylic acid mix to obtain mixed monomer, 56g epoxy resin E44 (WSR6101, purchased from Nantong Xingchen Synthetic Materials Co., Ltd. ) was dissolved in the mixed monomers, added into a four-necked flask with a built-in complex emulsifier solution, and stirred at a high speed for 1.5 h at a speed of 800 r / min to obtain a pre-emulsion. Take 1 / 10 of the pre-emulsion and mix the remaining 1 / 2 of the composite emulsifier emulsion, add to another four-necked flask, and add 1.8g of sodium bicarbonate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com