Microcrystalline foamed ceramic thermal insulation decoration composite plate and manufacturing method thereof

A technology of foam ceramics and microcrystalline ceramics, which is applied in the direction of ceramic layered products, chemical instruments and methods, hydraulic material layered products, etc., can solve the problems of heavy composite board, high reject rate, product damage, etc. Good thermal performance, low thermal conductivity and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

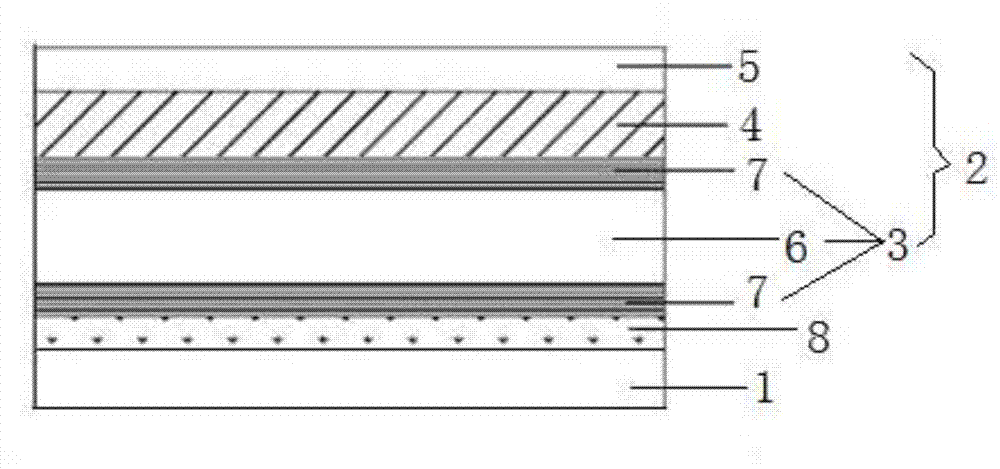

[0076] Such as figure 1 As shown, a microcrystalline foam ceramic thermal insulation and decorative composite board includes a thermal insulation layer 1 and a decorative layer 2 fixed on the thermal insulation layer 1 with a flame-retardant adhesive 8, and the thermal insulation layer 1 is a microcrystalline foam ceramic Insulation board, the decorative layer 2 is a flexible decorative covering material, which sequentially includes a flexible composite material sheet 3, a colored decorative mortar 4 and an overlay 5 from bottom to top, wherein the flame-retardant adhesive 8 It is a polymer modified cement mortar binder.

[0077] The thickness of the microcrystalline foam ceramic thermal insulation board is 50 mm; the thickness of the flexible decorative covering material is 15 mm; the specification of the microcrystalline foam ceramic thermal insulation and decorative composite board is length: 2000 mm; width: 1220 mm.

[0078] An interface agent is coated on both sides of t...

Embodiment 2

[0142] Such as figure 1 As shown, a microcrystalline foam ceramic thermal insulation and decorative composite board includes a thermal insulation layer 1 and a decorative layer 2 fixed on the thermal insulation layer 1 with a flame-retardant adhesive 8, and the thermal insulation layer 1 is a microcrystalline foam ceramic Insulation board, the decorative layer 2 is a flexible decorative covering material, which sequentially includes a flexible composite material sheet 3, a colored decorative mortar 4 and an overlay 5 from bottom to top, wherein the flame-retardant adhesive 8 It is a polymer modified cement mortar binder.

[0143] The thickness of the microcrystalline foam ceramic thermal insulation board is 700 mm, the thickness of the flexible decorative covering material is 30 mm, and the specifications of the microcrystalline foam ceramic thermal insulation and decorative composite board are length: 2440 mm; width: 1250 mm.

[0144] An interface agent is coated on both sid...

Embodiment 3

[0208] Such as figure 1 As shown, a microcrystalline foam ceramic thermal insulation and decorative composite board includes a thermal insulation layer 1 and a decorative layer 2 fixed on the thermal insulation layer 1 with a flame-retardant adhesive 8, and the thermal insulation layer 1 is a microcrystalline foam ceramic Insulation board, the decorative layer 2 is a flexible decorative covering material, which sequentially includes a flexible composite material sheet 3, a colored decorative mortar 4 and an overlay 5 from bottom to top, wherein the flame-retardant adhesive 8 It is a polymer modified cement mortar binder.

[0209]The thickness of the microcrystalline foam ceramic thermal insulation board is 300 mm, the thickness of the flexible decorative covering material is 25 mm, and the specification of the microcrystalline foam ceramic thermal insulation and decorative composite board is length: 3200 mm; width: 1500 mm.

[0210] An interface agent is coated on both sides ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com