Environment protection energy-saving type insulating block

A thermal insulation block, energy-saving technology, applied in thermal insulation, building components, sustainable waste treatment, etc., can solve the problem that the thermal insulation performance of concrete hollow blocks is not as good as that of solid clay bricks, and achieve good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An environment-friendly and energy-saving heat-insulating block, the components of the block and the proportions thereof are in parts by weight;

[0018] 59 parts of cement, 29 parts of fly ash, 6.5 parts of slag, and 1.09 parts of polyphenylene particles

[0019] 0.84 parts of redispersible latex powder 0.10 parts of hydroxypropyl methylcellulose (HPMC)

[0020] Wood fiber 0.14PP (polypropylene) fiber 0.03, water reducer 0.92, water-cement ratio 0.4

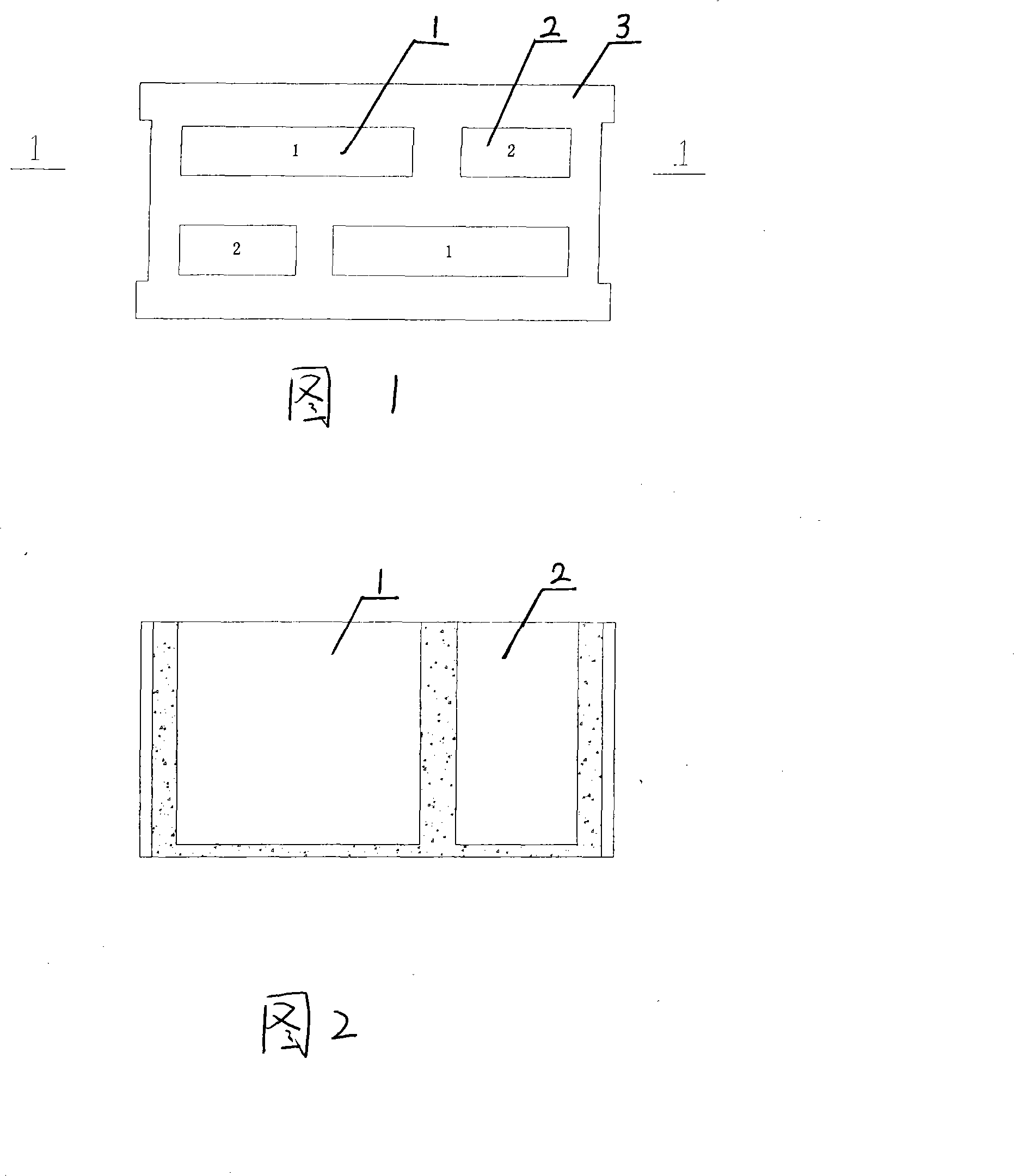

[0021] The hole type of the environmental protection and energy-saving thermal insulation block is semi-closed, the bottom thickness of each hole is 10mm, and each block is provided with double rows of holes, which are arranged in dislocation, that is, each row of holes is hole 1 and hole 2 combinations, the size of hole 1 is 190mm×45mm, and the size of hole 2 is 90mm×45mm.

Embodiment 2

[0023] An environment-friendly and energy-saving heat-insulating block, the components of the block and the proportions thereof are in parts by weight;

[0024] 61 parts of cement, 31 parts of fly ash, 6.7 parts of slag, 1.15 parts of polyphenylene particles

[0025] Redispersible latex powder 0.86 parts Hydroxypropyl methylcellulose (HPMC) 0.14 parts

[0026] Wood fiber 0.17PP (polypropylene) fiber 0.04, water reducer 0.98, water-cement ratio 0.46

[0027] The hole type of the environmental protection and energy-saving thermal insulation block is semi-closed, the bottom thickness of each hole is 10mm, and each block is provided with double rows of holes, which are arranged in dislocation, that is, each row of holes is hole 1 and hole 2 combinations, the size of hole 1 is 190mm×45mm, and the size of hole 2 is 90mm×45mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com