Sucking particles for heat-not-burn cigarettes and manufacturing method

A heat-not-burn and cigarette technology, which is applied in the manufacture of cigars, smokers’ supplies, tobacco, etc., can solve the problems of tobacco aroma substances loss, large difference in suction, uneven heating, etc., and achieve low process difficulty and good heating performance , the effect of rapid fogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

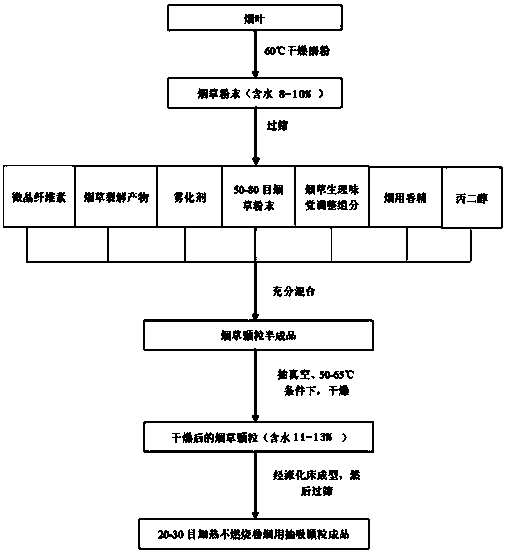

Image

Examples

Embodiment 1

[0035] A smoking granule for heat-not-burn cigarettes, comprising the following components in terms of weight fractions: 15.5 parts of microcrystalline cellulose, 50 parts of Luzhou-flavor flue-cured tobacco powder, 0.5 part of 280°C Zimbabwe flue-cured tobacco pyrolysis product, tobacco physiological taste adjustment 1 part of components, 30 parts of vegetable glycerin, 2 parts of tobacco essence, and 1 part of propylene glycol. The production steps are as follows:

[0036] 1. Dry and grind Luzhou-flavor flue-cured tobacco leaves, and control the water content to 8% at 60°C, then sieve, and take tobacco powder with a particle size of 50-80 mesh as raw material;

[0037] 2. The 50-80 mesh tobacco powder obtained in step 1 is fully mixed with microcrystalline cellulose, Zimbabwe flue-cured tobacco pyrolysis product at 280°C, tobacco physiological taste adjustment components, vegetable glycerin, tobacco essence, and propylene glycol, and then prepared Tobacco pellet semi-finish...

Embodiment 2

[0043] A smoking granule for heat-not-burn cigarettes, comprising the following components in terms of weight fractions: 20 parts of microcrystalline cellulose, 50 parts of Luzhou-flavor flue-cured tobacco powder, 2 parts of Zimbabwe flue-cured tobacco pyrolysis product at 250°C, tobacco physiological taste adjustment 1 part of components, 15 parts of vegetable glycerin, 2 parts of tobacco essence, and 10 parts of propylene glycol. The production steps are as follows:

[0044] 1. Dry and grind Luzhou-flavor flue-cured tobacco leaves, control the water content to 10% at 60°C, and then sieve, and take tobacco powder with a particle size of 50-80 mesh as raw material;

[0045] 2. The 50-80 mesh tobacco powder obtained in step 1 is fully mixed with microcrystalline cellulose, 250°C Zimbabwe flue-cured tobacco pyrolysis product, tobacco physiological taste adjustment component, vegetable glycerin, tobacco essence, and propylene glycol, and then prepared Tobacco pellet semi-finishe...

Embodiment 3

[0051] A smoking granule for heat-not-burn cigarettes, comprising the following components in terms of weight fractions: 12 parts of microcrystalline cellulose, 62.4 parts of Luzhou-flavor flue-cured tobacco powder, 2 parts of Zimbabwe flue-cured tobacco pyrolysis product at 280°C, tobacco physiological taste adjustment 1 part of components, 15 parts of vegetable glycerin, 0.1 part of tobacco essence, and 7.5 parts of propylene glycol. The production steps are as follows:

[0052] 1. Dry and grind Luzhou-flavor flue-cured tobacco leaves, control the water content to 9% at 60°C, then sieve, and take tobacco powder with a particle size of 50-80 mesh as raw material;

[0053] 2. The 50-80 mesh tobacco powder obtained in step 1 is fully mixed with microcrystalline cellulose, Zimbabwe flue-cured tobacco pyrolysis product at 280°C, tobacco physiological taste adjustment components, vegetable glycerin, tobacco essence, and propylene glycol, and then prepared Tobacco pellet semi-fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com