Environment-friendly type alkali lignin modified phenolic resin adhesive and preparation method thereof

A technology of alkali lignin and phenolic resin, applied in environment-friendly alkali lignin-modified phenolic resin adhesive and preparation thereof, in the field of phenolic resin adhesive, can solve the problem of increasing the water resistance replacement rate of modified phenolic resin adhesive and reducing the production cost of phenolic adhesive , the problem of high aldehyde content, to achieve high replacement rate, low cost, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

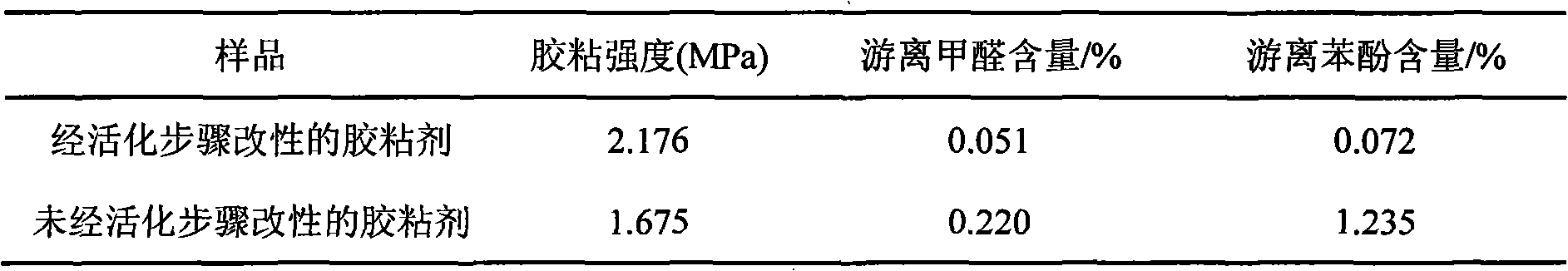

Examples

Embodiment 1

[0032] Weigh 800g of wheatgrass lignin into a flask, add 4500ml of water, and then add 15g of trifluoroacetic acid, seal it, and acidify it at 110°C for 1 hour. Filter, wash the insoluble matter with water, and then vacuum-dry at 50°C to constant weight to obtain desugared alkali lignin.

[0033] Take 20g of dry desugared alkali lignin powder, add 4g of NaOH, 150g of water, control the temperature at 80°C, and stir at constant temperature for 1 hour; cool the reaction solution to 50°C, add 1g of potassium peroxodisulfate, 2g of 2- Naphthol, react for 0.5 hours; cool the reaction solution to 45°C, add 55g of formaldehyde and 80g of phenol with a mass concentration of 37%, react at a constant temperature of 50°C for 30 minutes, and then heat up to 80°C at a rate of 1°C / min , constant temperature reaction for 1 hour; dropwise add 50g of formaldehyde with a mass concentration of 37%, continue the constant temperature reaction for 2 hours, take out 10ml of the reactant every 10 min...

Embodiment 2

[0035] Weigh 800g of bagasse alkali lignin into a flask, add 7500ml of water, add 60g of sulfuric acid, seal it, and acidify it at 120°C for 3 hours. Filter, wash the insoluble matter with water, and then vacuum-dry at 40°C to constant weight to obtain desugared alkali lignin.

[0036] Take 80g of dried desugared alkali lignin powder, add 15g of NaOH, 150g of water, control the temperature at 100°C, and stir at constant temperature for 2 hours; cool the reaction solution to 80°C, add 10g of sodium peroxide, 10g of 2-naphthalene Phenol, react for 3 hours, cool the reaction solution to 50°C, add 80g of formaldehyde and 80g of phenol with a mass concentration of 37%, react at a constant temperature of 50°C for 30 minutes, and then heat up to 80°C at a rate of 2°C / min , constant temperature reaction for 2 hours; dropwise add 30g of formaldehyde with a mass concentration of 37%, continue the constant temperature reaction for 1 hour, take out 10ml of reactant every 5 minutes, cool t...

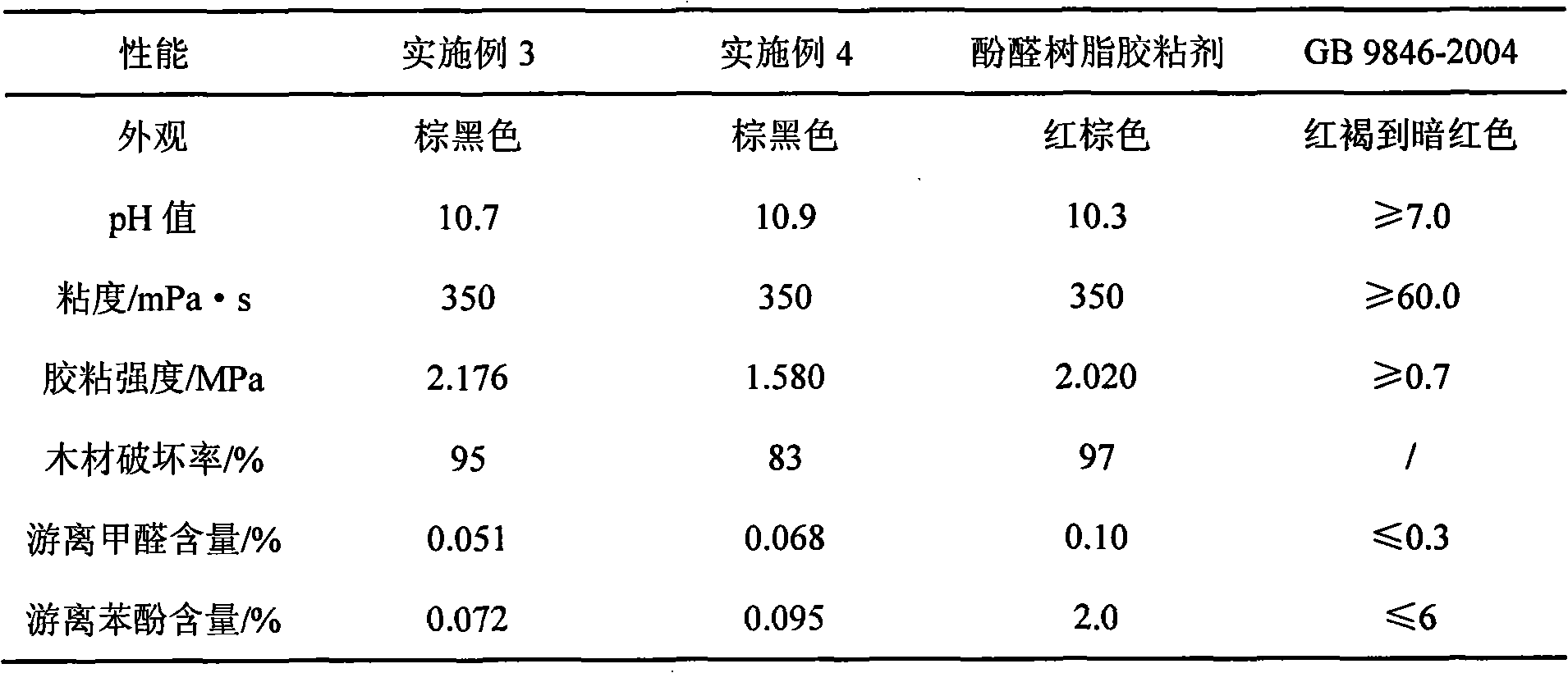

Embodiment 3

[0038] Weigh 800g of wheatgrass lignin into a flask, add 4500ml of water, and then add 15g of trifluoroacetic acid, seal it, and acidify it at 110°C for 1 hour. Filter, wash the insoluble matter with water, and then vacuum-dry at 60°C to constant weight to obtain desugared alkali lignin.

[0039] Take 40g of dry alkali lignin powder, add 12g of NaOH, 150g of water, control the temperature at 100°C, and stir for 1 hour; cool the reaction solution to 60°C, add 2g of potassium peroxodisulfate, 3.5g of 2-naphthol, React for 2 hours, add 80g of formaldehyde and 60g of phenol with a mass concentration of 37%, react at a constant temperature at 50°C for 30 minutes, then heat up to 80°C at a speed of 1°C / min, and react at a constant temperature for 1 hour; 30g of 37% formaldehyde, continue to react at constant temperature for 1 hour, take out a small amount of reactant every 15 minutes, cool to 25°C to measure its viscosity, when the viscosity reaches 350mPa.s, quickly cool to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com