Crystalline light transmitting porcelain plate painting showing structure and preparation process thereof

A preparation process and technology of porcelain plate painting, which is applied in the direction of decorative art and art painting, can solve the problems that the artistic conception of porcelain plate painting cannot be fully presented, the quality of porcelain is not fine enough, and porcelain plate painting is easy to fall off, etc., so as to reduce The difficulty of energy transition, long luminous time, and the effect of increasing decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

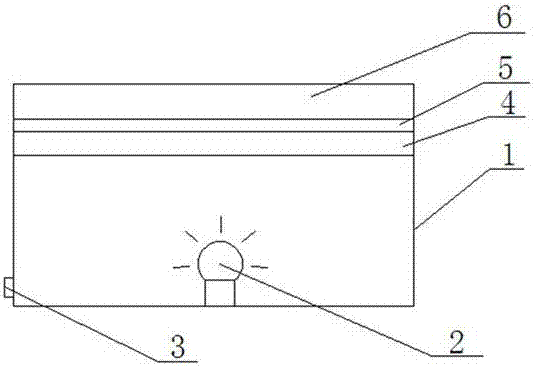

[0027] A crystalline light-transmitting porcelain plate painting display structure comprises a light box 1 with an upper opening, a light source 2 is arranged inside the light box 1, a power switch 3 is arranged outside the light box 1, and a glass plate layer for sealing is fixed on the opening of the light box 1 4. The glass plate layer 4 is bonded with the porcelain plate painting 6 through the light-transmitting shadowless glue layer 5, and the lower surface of the glass plate layer 4 is etched and multi-angle polished to form a curved surface with different curvatures and a refraction surface combined with a bevel, In order to make the light hit the refraction surface to form different refraction paths, and then the light source 2 is projected onto the porcelain plate painting 6 from multiple angles through the glass plate layer 4 and the shadowless glue layer 5 to achieve different light transmission effects.

[0028] The raw materials for the preparation of the glass pla...

Embodiment 2

[0045] A crystalline light-transmitting porcelain plate painting display structure comprises a light box 1 with an upper opening, a light source 2 is arranged inside the light box 1, a power switch 3 is arranged outside the light box 1, and a glass plate layer for sealing is fixed on the opening of the light box 1 4. The glass plate layer 4 is bonded with the porcelain plate painting 6 through the light-transmitting shadowless glue layer 5, and the lower surface of the glass plate layer 4 is etched and multi-angle polished to form a curved surface with different curvatures and a refraction surface combined with a bevel, In order to make the light hit the refraction surface to form different refraction paths, and then the light source 2 is projected onto the porcelain plate painting 6 from multiple angles through the glass plate layer 4 and the shadowless glue layer 5 to achieve different light transmission effects.

[0046] The raw materials for the preparation of the glass pla...

Embodiment 3

[0063] A crystalline light-transmitting porcelain plate painting display structure comprises a light box 1 with an upper opening, a light source 2 is arranged inside the light box 1, a power switch 3 is arranged outside the light box 1, and a glass plate layer for sealing is fixed on the opening of the light box 1 4. The glass plate layer 4 is bonded with the porcelain plate painting 6 through the light-transmitting shadowless glue layer 5, and the lower surface of the glass plate layer 4 is etched and multi-angle polished to form a curved surface with different curvatures and a refraction surface combined with a bevel, In order to make the light hit the refraction surface to form different refraction paths, and then the light source 2 is projected onto the porcelain plate painting 6 from multiple angles through the glass plate layer 4 and the shadowless glue layer 5 to achieve different light transmission effects.

[0064] The raw materials for the preparation of the glass pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com