Preparation method and glaze material of celadon secret color glaze

A technology of secret color and celadon, which is applied in the field of preparation of celadon secret color glaze, can solve the problems of difficult control of firing temperature, low yield rate, difficult selection of celadon secret color glaze glaze, etc., and achieves easy implementation and high product yield rate , The scientific and reasonable effect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

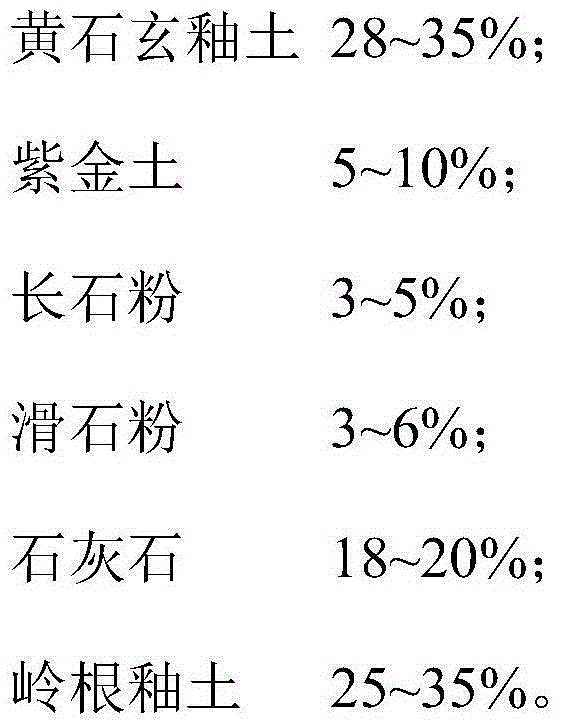

[0028] Correspondingly, the present invention also provides a preparation method of celadon secret color glaze, comprising the following steps: adding 28-35% of yellowstone xuan glaze soil, 5-10% of purple gold soil, 3-5% of feldspar powder, and 3-6% of talc powder %, 18-20% of limestone and 25-35% of ridge root glaze soil are mixed to obtain the glaze; the ball stone with a weight ratio of 1.3-1.5:1:0.8-0.9, the glaze and water are mixed and ground to obtain Glaze slurry; after the porcelain body is dried, it is biscuit fired at 840-880°C and cooled; the glaze slurry is adjusted to a water content of 38-45%, and the inner glaze is applied to the porcelain body by the glaze method, and then dipped in glaze The outer glaze is applied to the porcelain body; the glazed porcelain body is glazed and fired, and the glaze firing includes the evaporation stage, the reduction stage, the porcelain forming stage and the heat preservation stage in sequence, and the temperature of the porce...

Embodiment 1

[0042]The weight percentage composition of the glaze ingredients: Huangshixuan glazed soil 32%, purple gold soil 8%, feldspar powder 5%, talcum powder 5%, limestone 20%, linggen glazed soil 30%.

[0043] All kinds of glaze slurry are finely selected according to the formula requirements, mixed evenly, and then ball stone: glaze: water ratio of 1.3:1:0.9 is put into the grinding equipment to grind into glaze slurry.

[0044] After drying, it goes into the kiln for 6 hours of biscuit firing, then slowly fires with a warm fire until the temperature reaches 840°C and stops. After 15 hours of natural cooling, the biscuit comes out of the kiln, and the biscuit is then painted with powder and glazed. . The glazing of the biscuit is divided into two processes: inner and outer glazing. First, adjust the celadon secret color glaze slurry to a water content of 38%, and then apply the inner glaze of the bisque by the second glaze method, and the thickness of the glaze layer is controlled ...

Embodiment 2

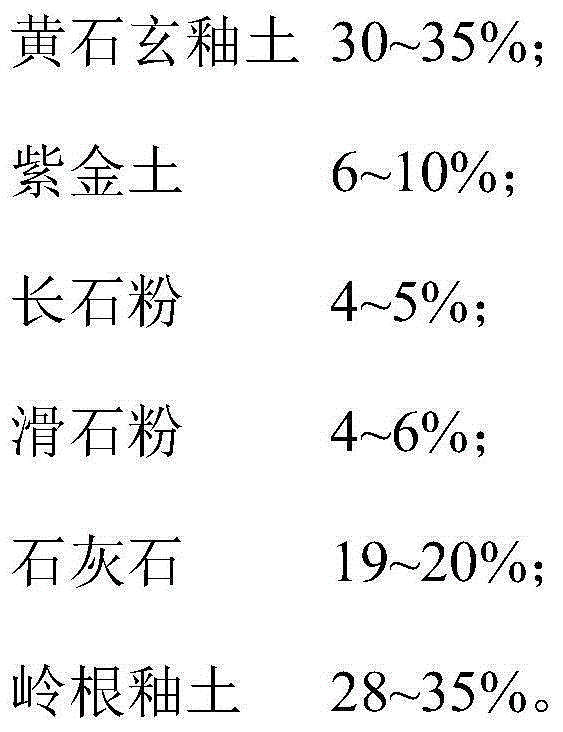

[0048] The weight percentage composition of the glaze ingredients: 31% of Huangshixuan glazed soil, 6% of purple gold soil, 3% of feldspar powder, 6% of talc powder, 19% of limestone, and 35% of Linggen glazed soil.

[0049] All kinds of glaze slurry are finely selected according to the formula requirements, mixed evenly, and then ball stone: glaze: water ratio: 1.5:1:0.8, put into the grinding equipment and grind into glaze slurry.

[0050] A seven-inch octagonal bottle is molded from porcelain clay, and after drying, it goes into the kiln for 7 hours of biscuit firing, then slowly fires at a warm fire until the temperature is 880°C and stops. After 20 hours of natural cooling, the biscuit comes out of the kiln, and then painted with powder and glazed. The glazing of the biscuit is divided into two processes: inner glaze and outer glaze. First, the glaze slurry is adjusted to a water content of 45%, and then the inner glaze of the biscuit is applied by the second glaze method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com