Manufacture method of square bricks

A technology for square bricks and raw materials, applied in the field of building materials, can solve the problems of lack of economical, environmental protection and effective treatment methods, occupation of space, prominent environmental problems, etc., and achieve the effects of reducing environmental pollution, improving strength and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A kind of preparation method that the present invention is used for square brick comprises the following steps:

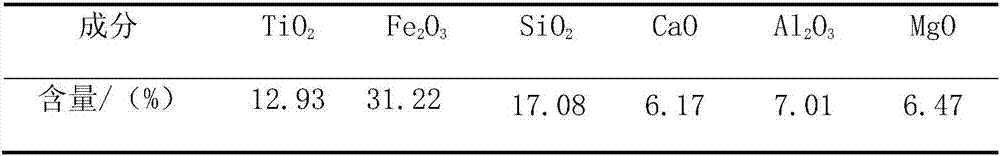

[0020] 1) Prepare the raw materials, and mix the raw materials uniformly through a mixer to obtain the first mixed material, wherein the raw materials are 58%-65% of vanadium extraction tailings, 1%-3% of aluminate cement, and 18% of clay. 22%, ferrosilicon ash 3%-10%, aluminum oxide powder 6%-10%, and fly ash 4%-8%; in order to make the raw materials fully stirred evenly, there are less lumps, and the vanadium tailings The water content is less than 2% of its weight, the water content of aluminate cement is less than 2% of its weight, the water content of clay is less than 2% of its weight, the water content of ferrosilicon ash is less than 2% of its weight, and the aluminum oxide powder contains The water content is less than 2% of its weight, and the water content of the aluminum oxide powder is less than 2% of its weight. If the moisture of the raw mater...

Embodiment 1

[0029] 1) Prepare the raw materials, and mix the raw materials uniformly through a mixer to obtain the first mixed material, wherein the raw materials are calculated as 58% of vanadium extraction tailings, 2% of aluminate cement, 18% of clay, 10% of ferrosilicon ash, Aluminum oxide powder 6% and fly ash 6%;

[0030] 2) adding water of 4% of the total weight of raw materials to the first mixture, stirring evenly to obtain the second mixture;

[0031] 3) Pour the second mixture into the mold, and form it by blowing to obtain the semi-finished square brick;

[0032] 4) Calcining the semi-finished square bricks at a high temperature between 900°C and 1200°C to obtain finished square bricks.

[0033] After testing, the compressive strength of the finished square brick is 52-60MPa, and the water absorption rate is 3-4%, which meets the use requirements of the square brick.

Embodiment 2

[0035] 1) Prepare the raw materials, and mix the raw materials uniformly through a mixer to obtain the first mixed material, wherein the raw materials are calculated as 60% of vanadium extraction tailings, 1% of aluminate cement, 22% of clay, 4% of ferrosilicon ash, Aluminum oxide powder 7% and fly ash 6%;

[0036] 2) Adding 6% water of the total weight of raw materials to the first mixture, stirring evenly to obtain the second mixture;

[0037] 3) Pour the second mixture into the mold, and form it by blowing to obtain the semi-finished square brick;

[0038] 4) Calcining the semi-finished square bricks at a high temperature between 900°C and 1200°C to obtain finished square bricks.

[0039] After testing, the compressive strength of the finished square brick is 53-57MPa, and the water absorption rate is 2-4%, which meets the use requirements of the square brick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com