High-brightness ivory white ceramic product and making process thereof

A technology of ceramic products and manufacturing process, which is applied in the field of ceramics, can solve the problems of not meeting consumers' aesthetic standards and low surface gloss, and achieve the effect of improving thermal stability, good gloss, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-brightness ivory white ceramic product, comprising a green body and a glaze layer applied to the surface of the green body, the green body is composed of the following components:

[0030]

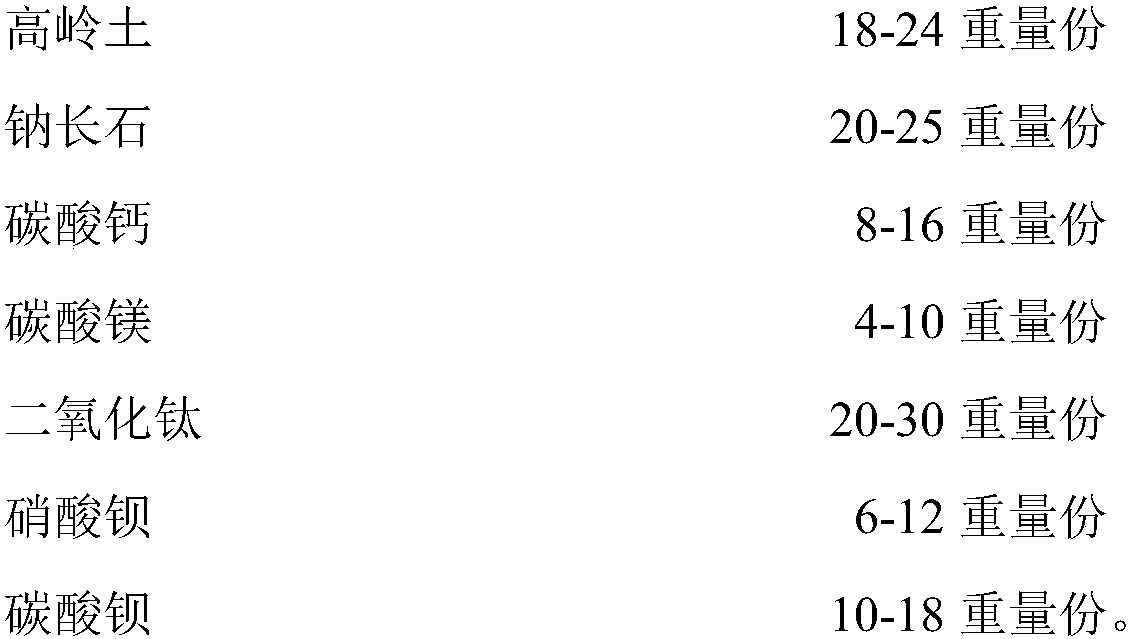

[0031] The glaze layer consists of the following components:

[0032]

[0033] Specifically, the flux consists of the following components:

[0034] Sodium oxide 3 parts by weight

[0035] Calcium oxide 2 parts by weight

[0036] 3 parts by weight of sodium silicate.

[0037] The manufacturing process of the above-mentioned high-brightness ivory white ceramic products comprises the following steps:

[0038] S1 Raw material preparation: Weigh each raw material according to parts by weight, and set aside;

[0039] S2 green body production: mix the green body raw materials and add water, then use alumina balls as the ball milling medium to carry out ball milling, remove iron after ball milling to obtain green body mud, shape the green body mud, carry out billet sharpen...

Embodiment 2

[0046] A high-brightness ivory white ceramic product, comprising a green body and a glaze layer applied to the surface of the green body, the green body is composed of the following components:

[0047]

[0048] The glaze layer consists of the following components:

[0049]

[0050] Specifically, the flux consists of the following components:

[0051] Sodium oxide 4 parts by weight

[0052] Calcium oxide 2.5 parts by weight

[0053] Sodium silicate 3.5 parts by weight.

[0054] The manufacturing process of the above-mentioned high-brightness ivory white ceramic products comprises the following steps:

[0055] S1 Raw material preparation: Weigh each raw material according to parts by weight, and set aside;

[0056] S2 green body production: mix the green body raw materials and add water, then use alumina balls as the ball milling medium to carry out ball milling, remove iron after ball milling to obtain green body mud, shape the green body mud, carry out billet sharpe...

Embodiment 3

[0063] A high-brightness ivory white ceramic product, comprising a green body and a glaze layer applied to the surface of the green body, the green body is composed of the following components:

[0064]

[0065] The glaze layer consists of the following components:

[0066]

[0067] Specifically, the flux consists of the following components:

[0068] Sodium oxide 4 parts by weight

[0069] Calcium oxide 2.5 parts by weight

[0070] Sodium silicate 3.5 parts by weight.

[0071] The manufacturing process of the above-mentioned high-brightness ivory white ceramic products comprises the following steps:

[0072] S1 Raw material preparation: Weigh each raw material according to parts by weight, and set aside;

[0073] S2 green body production: mix the green body raw materials and add water, then use alumina balls as the ball milling medium to carry out ball milling, remove iron after ball milling to obtain green body mud, shape the green body mud, carry out billet sharpeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com