Lithium ion battery and preparation method thereof

A lithium-ion battery and ionic liquid technology, applied in the field of lithium-ion batteries and their preparation, can solve the problems of low electronic conductivity and ion diffusion rate, low initial charge and discharge efficiency, and inability to meet high voltage, etc., and achieve a wide electrochemical window , excellent charging and discharging platform, good cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

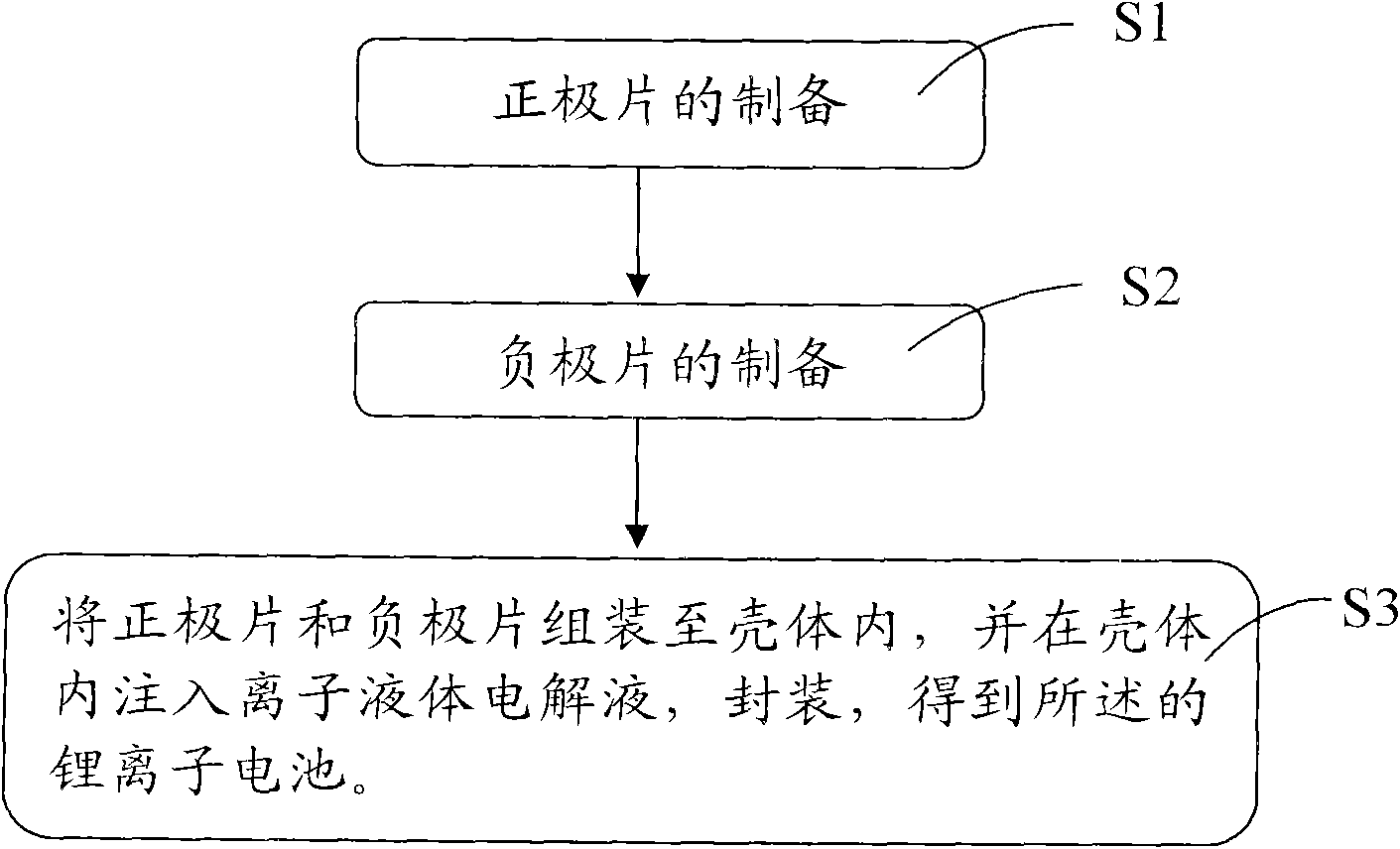

[0034] The embodiment of the present invention also provides the preparation method of above-mentioned lithium ion battery, see figure 1 and figure 2 shown, including the following steps:

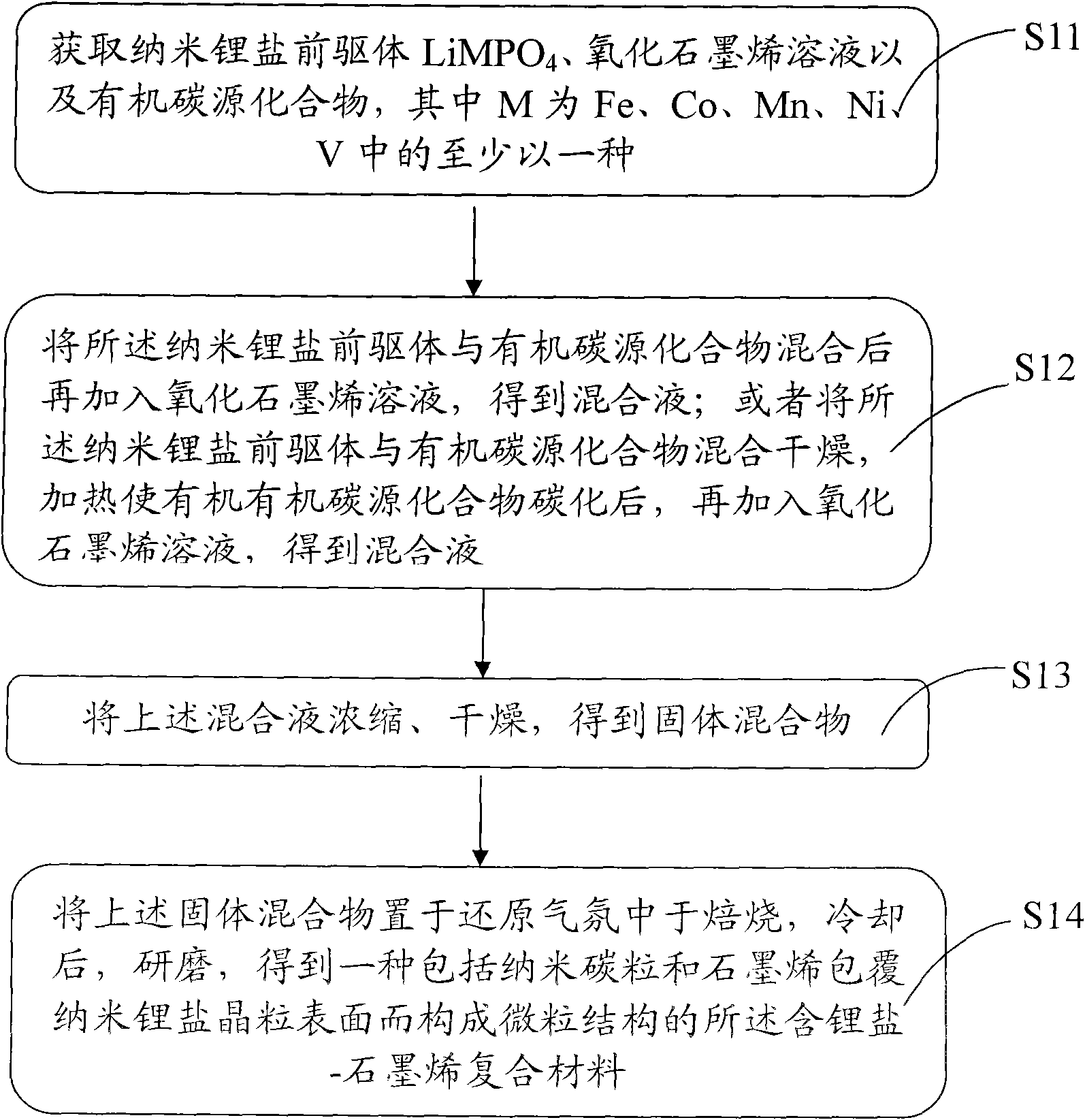

[0035] S1. Preparation of positive electrode sheet 21: preparation of LiMPO 4 - graphene composite, then the LiMPO 4 -The positive electrode coating solution prepared by mixing the graphene composite with the conductive agent and the binder is coated on the positive electrode substrate to form the positive electrode sheet 21, wherein M is at least one of Fe, Co, Mn, Ni, V in one kind;

[0036] S2. Preparation of the negative electrode sheet 22: obtaining Li 4 Ti 5 o 12 and graphene oxide solution, and then the Li 4 Ti 5 o 12 After the precursor is mixed with the graphene oxide solution, followed by drying, roasting under anaerobic conditions, and cooling to obtain the Li 4 Ti 5 o 12 - graphene composite, then the Li 4 Ti 5 o 12 -The negative electrode coating solution prepar...

Embodiment 1

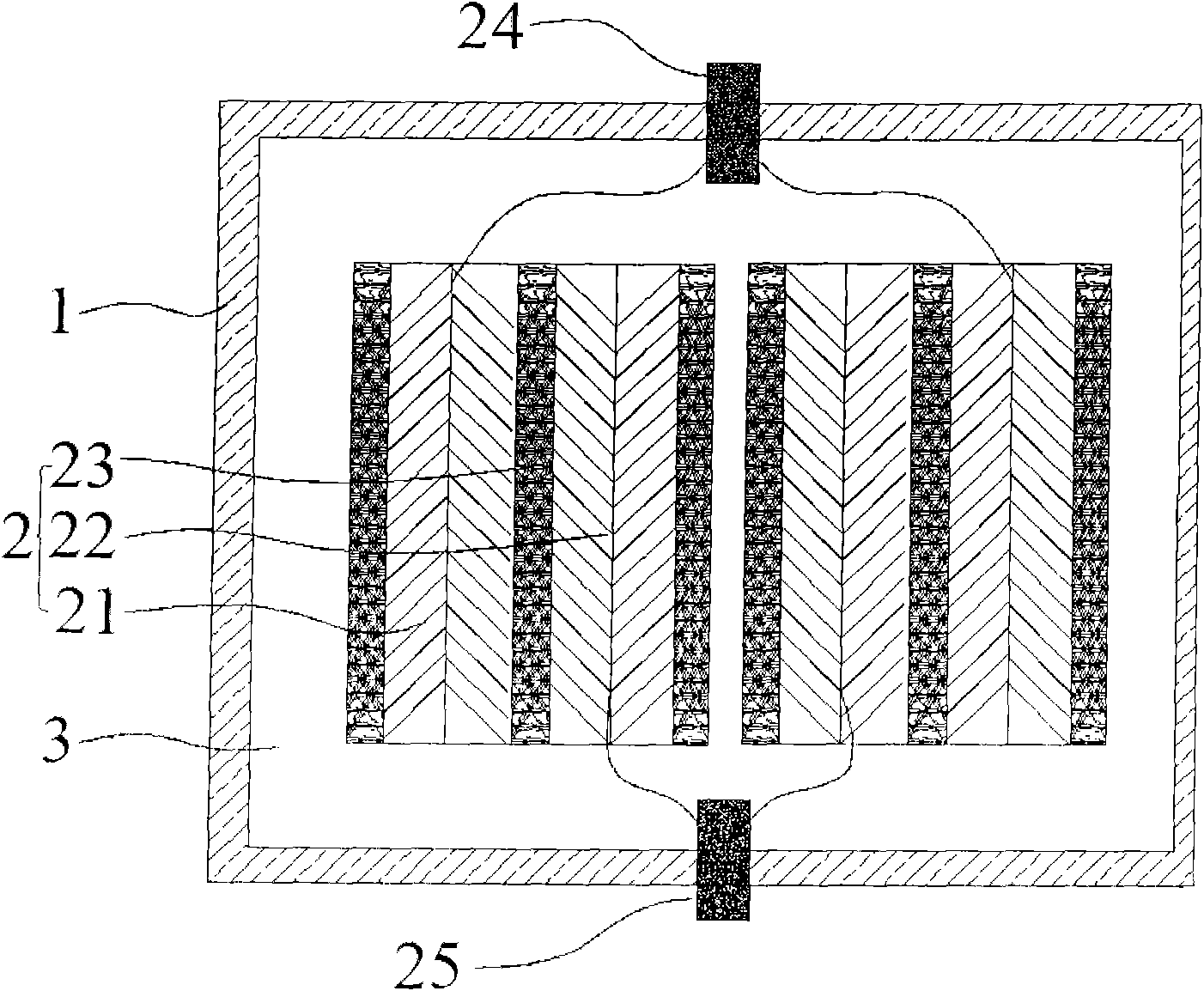

[0061] Lithium-ion battery structure such as figure 1 As shown, the lithium-ion battery includes a casing 1 , a cell 2 wrapped in the casing 1 , and an ionic liquid electrolyte 3 , and the electrolyte 3 is distributed around the cell 2 . The battery cell 2 includes a positive pole piece 21, a negative pole piece 22 and a diaphragm 23. The polypropylene diaphragm 23 separates the positive pole piece 21 from the negative pole piece 22, and the positive pole tab 24 and the negative pole tab 25 are respectively drawn from the positive pole piece 21 and the negative pole piece 22. , one end of the positive pole tab 24 and one end of the negative pole tab 25 extend out of the casing 1; the positive pole sheet 21 comprises aluminum foil and a positive coating bonded on the surface of the aluminum foil, the positive coating is LiFePO by mass ratio 4 -Graphene composite: acetylene black: polyvinylidene fluoride (PVDF) is a mixture of 84:8:8, the thickness of the positive electrode coat...

Embodiment 2

[0075] Lithium-ion battery structure is the same as embodiment 1, and wherein, positive electrode coating thickness is 50 μ m, and negative electrode coating thickness is 50 μ m, and ionic liquid electrolyte solution 3 is the N that concentration is 1mol / L, N-diethyl-N-methyl- N-methoxyethyl tetrafluoroborate solution. see details figure 1 shown.

[0076] The lithium-ion battery is assembled and left to stand for 12 hours to be tested. The test method is the same as in Example 1, and its performance is similar Figure 5 shown.

[0077] Among them, the cathode material is LiMnPO 4 / Preparation of graphene:

[0078] (1) LiMnPO 4 Preparation: 1moL of NH 4 h 2 PO 4 and 1moL of MnSO 4 Dissolve in deionized water to form a uniformly dispersed mixture with a concentration of 0.5mol / L. Slowly add 1moL of LiOH solution to the mixture under stirring, and pass in nitrogen as a protective gas to prevent the oxidation of ferrous iron to obtain pale gray Precipitate, continue to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com