Gas generating system

a gas generation system and gas generation technology, applied in the direction of pressure gas generation, explosives, weapons, etc., can solve the problems of unacceptably high toxic gas levels, poor thermal stability of nonazide gas generant compositions, and inability to produce toxic gases, etc., to reduce hygroscopicity, reduce the effect of solid combustion products, and optimize the production of gas combustion products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

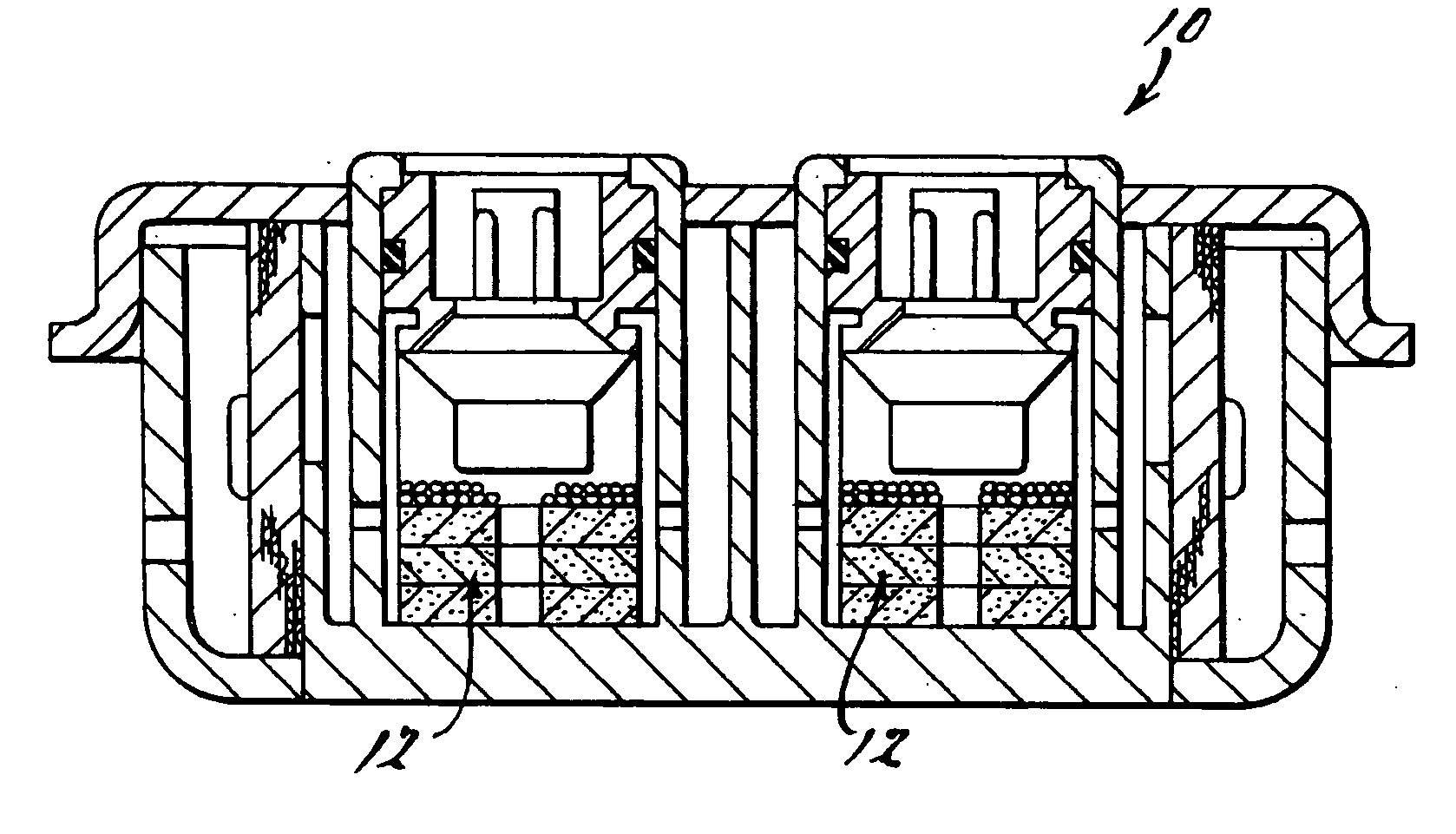

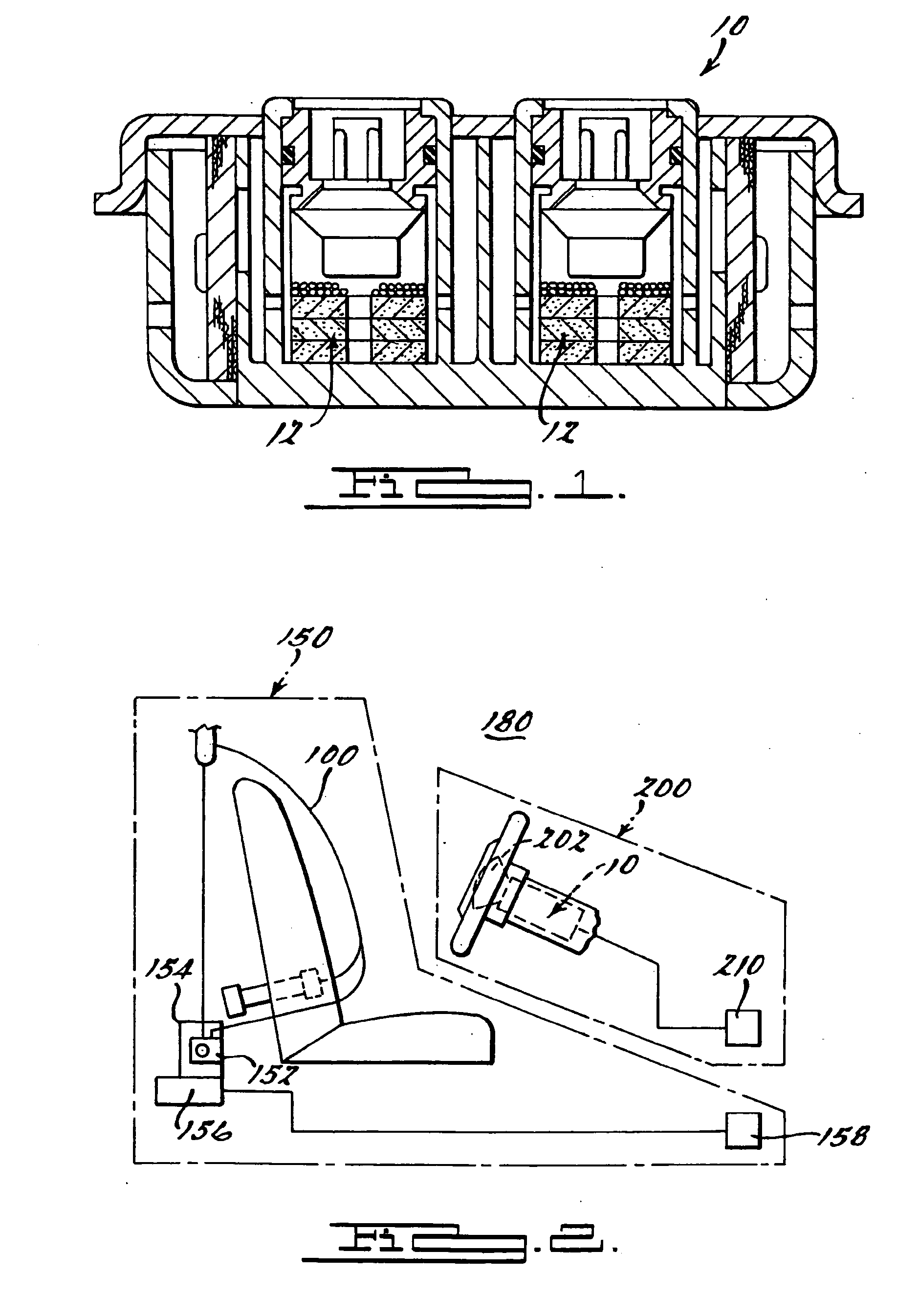

Image

Examples

Embodiment Construction

)

[0015] The present invention includes gas generant compositions that contain a fuel, an oxidizer, and a primary binder. The primary binder is selected from the group of cellulosic polymers wherein each polymeric binder contains carboxyl functionality, alkyl functionality, and hydroxyl functionality. Stated another way, A preferred binder selected from this group is carboxymethylcellulose acetate butyrate (CMCAB). Other carboxy alkyl celluloses binders are contemplated, and are exemplified by those compounds containing a cellulose backbone substituted with both carboxyl substitutions and alkyl substitutions, and salts of these compounds including nonmetal, metal, and alkali and alkaline earth metal salts including potassium, sodium, strontium, and ammonium salts thereof. These salts may be formed simply be reacting the carboxy alkyl celluloses with a base such as potassium hydroxide or ammonium hydroxide.

[0016] Carboxyl substitutions include carboxymethyl, succinyl, and maleyl grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame temperatures | aaaaa | aaaaa |

| compositions | aaaaa | aaaaa |

| combustion properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com