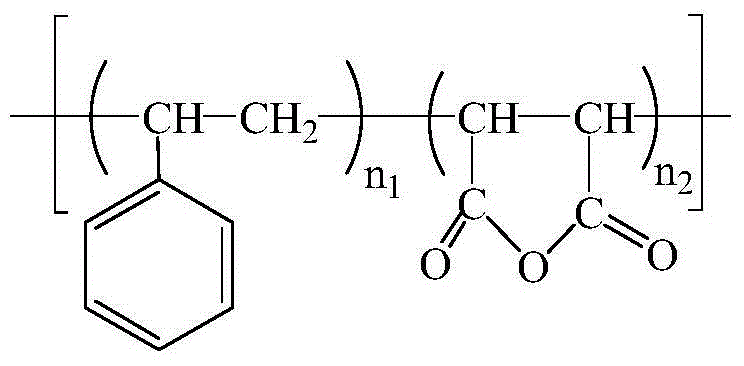

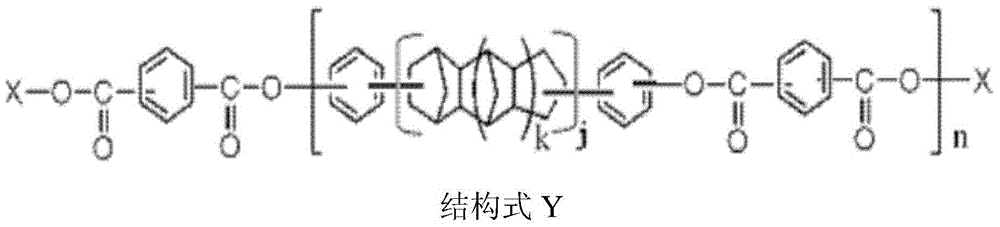

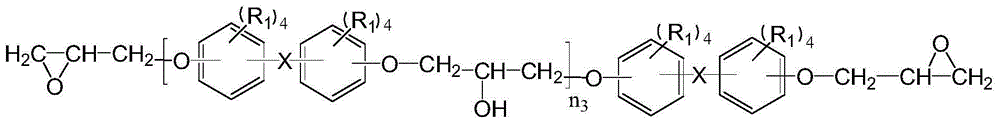

Thermosetting resin composition and application thereof

A resin composition, thermosetting technology, applied in synthetic resin layered products, electrical components, printed circuits, etc., can solve the problems of low glass transition temperature, low heat resistance, and low product qualification rate of cured products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]Using 35 parts of active ester 1 containing styrene structure (m / n=8, produced by SHINA, model: SAP820), 30 parts of HP7200, 15 parts of BT93, 20 parts of SC2050, 0.1 part of catalyst 2-MI, the above compound was synthesized using MEK Dissolved and adjusted to a suitable viscosity glue. Use 2116-type electronic grade glass cloth to soak the glue, and remove the solvent in an oven at 155°C to obtain a B-stage prepreg sample. The sum of the mass parts of the styrene structure active ester, HP7200, BT93 and SC2050 is 100 parts.

[0080] Eight pieces of prepreg and two pieces of one-ounce electrolytic copper foil are stacked together and laminated by a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120°C, the heating rate is controlled at 1.0-3.0 degrees / minute; 2. The pressure is set at 20kg / cm 2 ; 3. The curing temperature is 190 ℃, and keep this temperature for 90 minutes. The co...

Embodiment 2

[0082] Use 50 parts of active ester 1 containing styrene structure (m / n=8, produced by SHINA, model: SAP820), 25 parts of EPPN501H epoxy resin, 20 parts of SAYTEX8010 decabromodiphenylethane, 5 parts of kaolin, 0.075 parts of catalyst For N,N-dimethyl-pyridinamine, use toluene to dissolve the above compound and prepare a glue with a suitable viscosity. Use a polyester non-woven fabric to soak the glue, and remove the solvent in an oven at 155°C to obtain a B-stage prepreg sample. The sum of the mass parts of the styrene structure active ester, EPPN501H epoxy resin, decabromodiphenylethane and kaolin is 100 parts.

[0083] Eight pieces of prepreg and two pieces of one-ounce electrolytic copper foil are stacked together and laminated by a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120 degrees, the heating rate is controlled at 1.0-3.0 degrees / minute; 2. The pressure is set at 20kg / cm ...

Embodiment 3

[0085] Use 60 parts of active ester 1 containing styrene structure (m / n=8, produced by SHINA, model: SAP820), 30 parts of AG-80 epoxy resin, 10 parts of polytetrafluoroethylene powder, 0.1 part of catalyst butyltriphenyl Phosphine chloride, use DMF to dissolve the above compound, and prepare a glue with a suitable viscosity. Use 2116-type electronic grade glass cloth to soak the glue, and remove the solvent in an oven at 155°C to obtain a B-stage prepreg sample. The sum of the mass parts of the styrene structure active ester and the AG-80 epoxy resin polytetrafluoroethylene powder is 100 parts.

[0086] Eight pieces of prepreg and two pieces of one-ounce electrolytic copper foil are stacked together and laminated by a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the material temperature is 80-120°C, the heating rate is controlled at 1.0-3.0 degrees / minute; 2. The pressure is set at 20kg / cm 2 ; 3. The curing temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com