Patents

Literature

54results about How to "Small dielectric loss tangent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

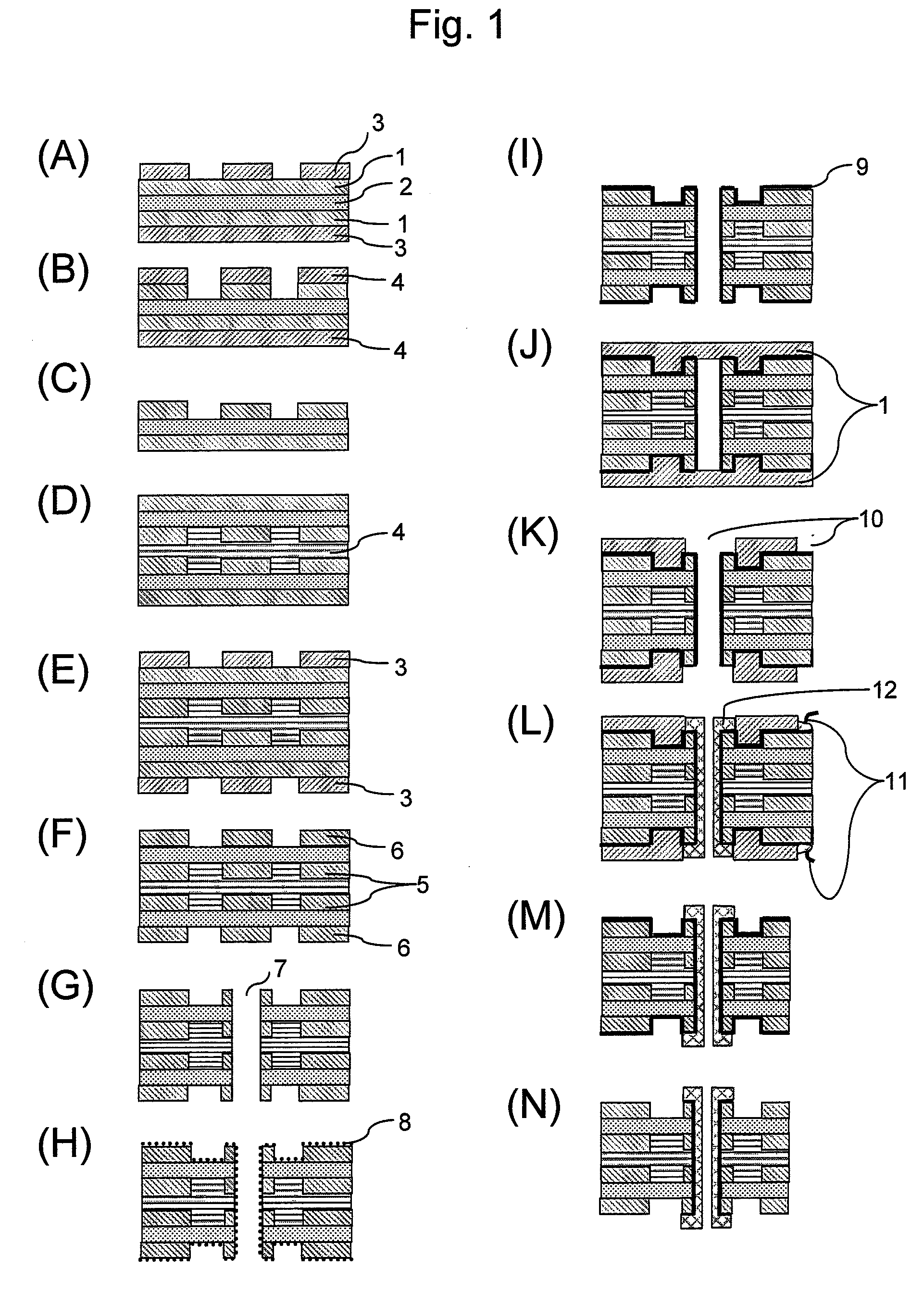

Composite particle for dielectrics, ultramicroparticulate composite resin particle, composition for forming dielectrics and use thereof

InactiveUS7169327B2High dielectric constantSmall dielectric loss tangentSemiconductor/solid-state device detailsSolid-state devicesInorganic particleInorganic particles

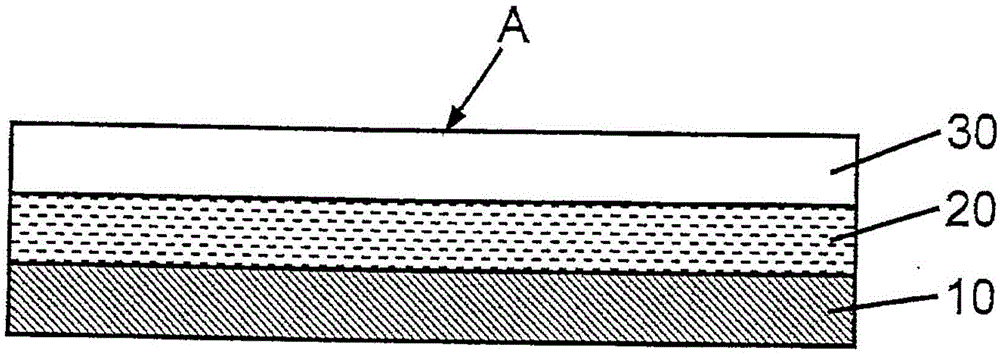

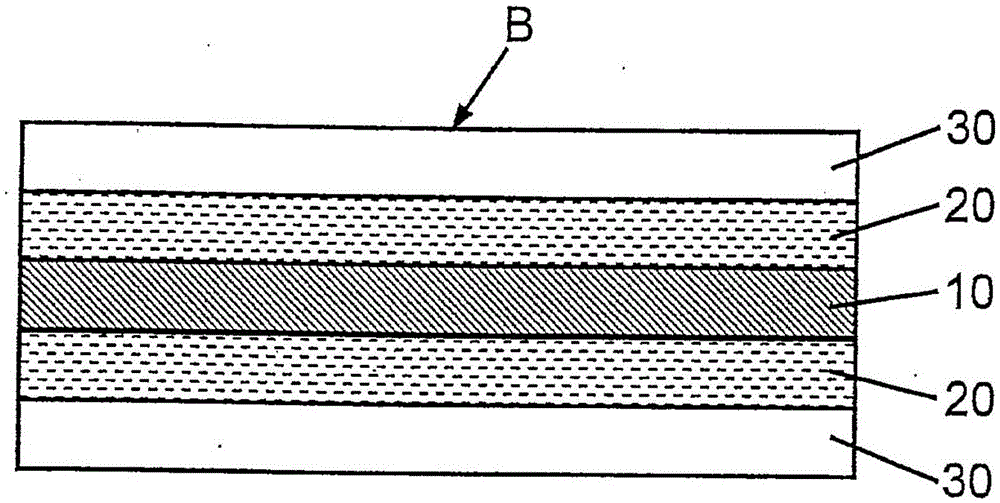

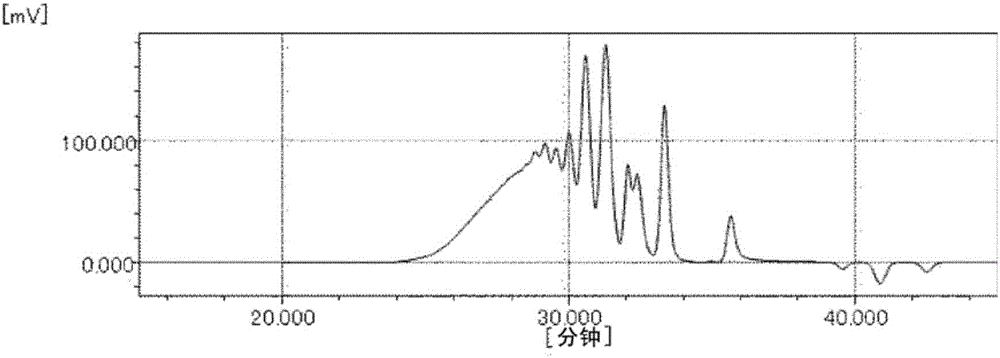

The dielectric-forming composition according to the invention is characterized by consisting of:composite particles for dielectrics in which part or all of the surfaces of inorganic particles with permittivity of 30 or greater are coated with a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material; and(B) a resin component constituted of at least one of a polymerizable compound and a polymer.In addition, another dielectric-forming composition according to the invention is characterized by containing:ultrafine particle-resin composite particles composed of (J) inorganic ultrafine particles with the average particle size of 0.1 μm or smaller, and (B) a resin component constituted of at least one of a polymerizable compound and a polymer, wherein part or all of the surfaces of the inorganic ultrafine particles (J) are coated with the resin component (B), and the ultrafine particle-resin composite particles contain 20% by weight or more of the inorganic ultrafine particles (J); andinorganic particles with the average particle size of 0.1 to 2 μm and permittivity of 30 or greater, or inorganic composite particles in which a conductive metal or a compound thereof, or a conductive organic compound or a conductive inorganic material is deposited on the part or all of the surfaces of the inorganic particles.

Owner:JSR CORPORATIOON

Polyimide Resin Composition, Polymer Film Containing Polymide Resin and Laminate Using the Same, and Method for Manufacturing Printed Wiring Board

InactiveUS20070269665A1High heating temperatureImprove featuresInsulating substrate metal adhesion improvementSynthetic resin layered productsHigh humidityThiol

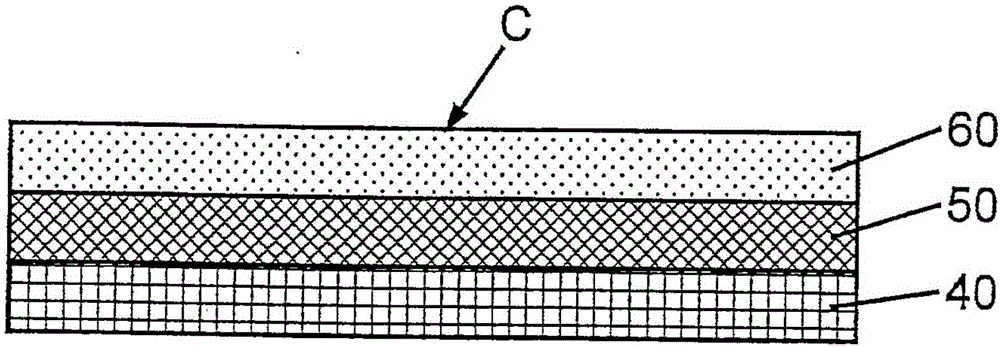

The present invention relates to a polyimide resin composition including an organic thiol compound and a thermoplastic polyimide resin, a polymeric film containing the polyimide resin, a laminate including the same, and a printed circuit board. By using the polyimide resin composition, it is possible to form an electroless plating film having high adhesive strength even under high-temperature, high-humidity conditions in spite of the fact that the surface roughness of the insulating layer is extremely low. Furthermore, by using the polymeric film and a laminate including the polymeric film and a metal layer, it is possible to obtain a printed circuit board capable of forming high-density circuit and having excellent adhesiveness, and excellent adhesion reliability in a high-temperature, high-humidity environment.

Owner:KANEKA CORP

Thermosetting resin composition and application thereof

InactiveCN104892902ALow dielectric constantLow water absorptionSynthetic resin layered productsPrinted circuit aspectsEpoxyDielectric loss

The present invention discloses a thermosetting resin composition, which comprises epoxy resin with 2 or more than 2 epoxy groups in each resin molecule; and active ester containing styrene structure. The thermosetting resin composition is used to prepare resin sheet, resin composite metal copper foil, prepreg, laminate, copper clad laminate, printed circuit board and the like. The thermosetting resin composition significantly reduces the probability of delamination in PCB substrate, and the obtained resin composition has excellent thermal stability and moisture-heat resistance, low dielectric constant and dielectric loss angle tangent, and excellent flame retardancy.

Owner:GUANGDONG SHENGYI SCI TECH

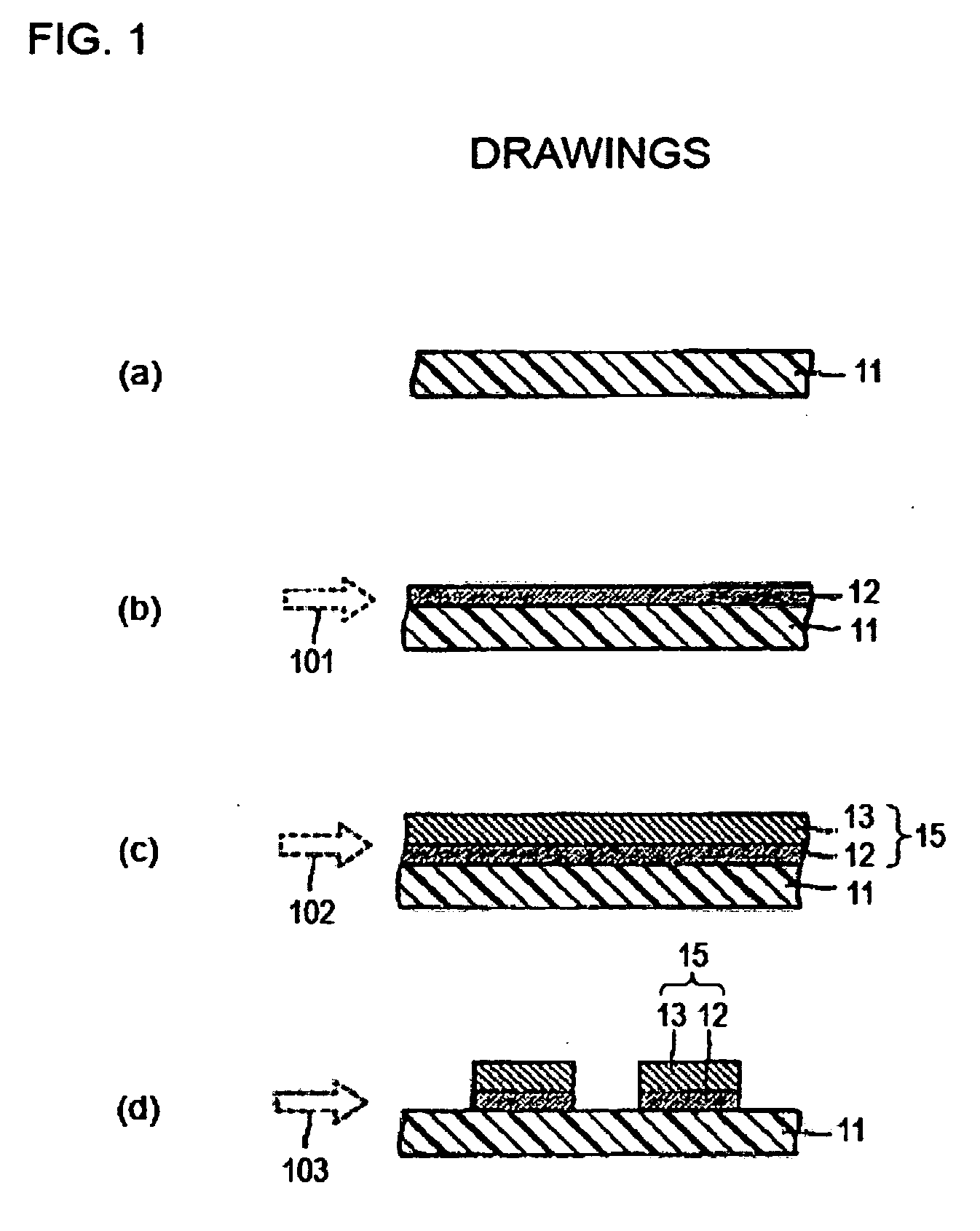

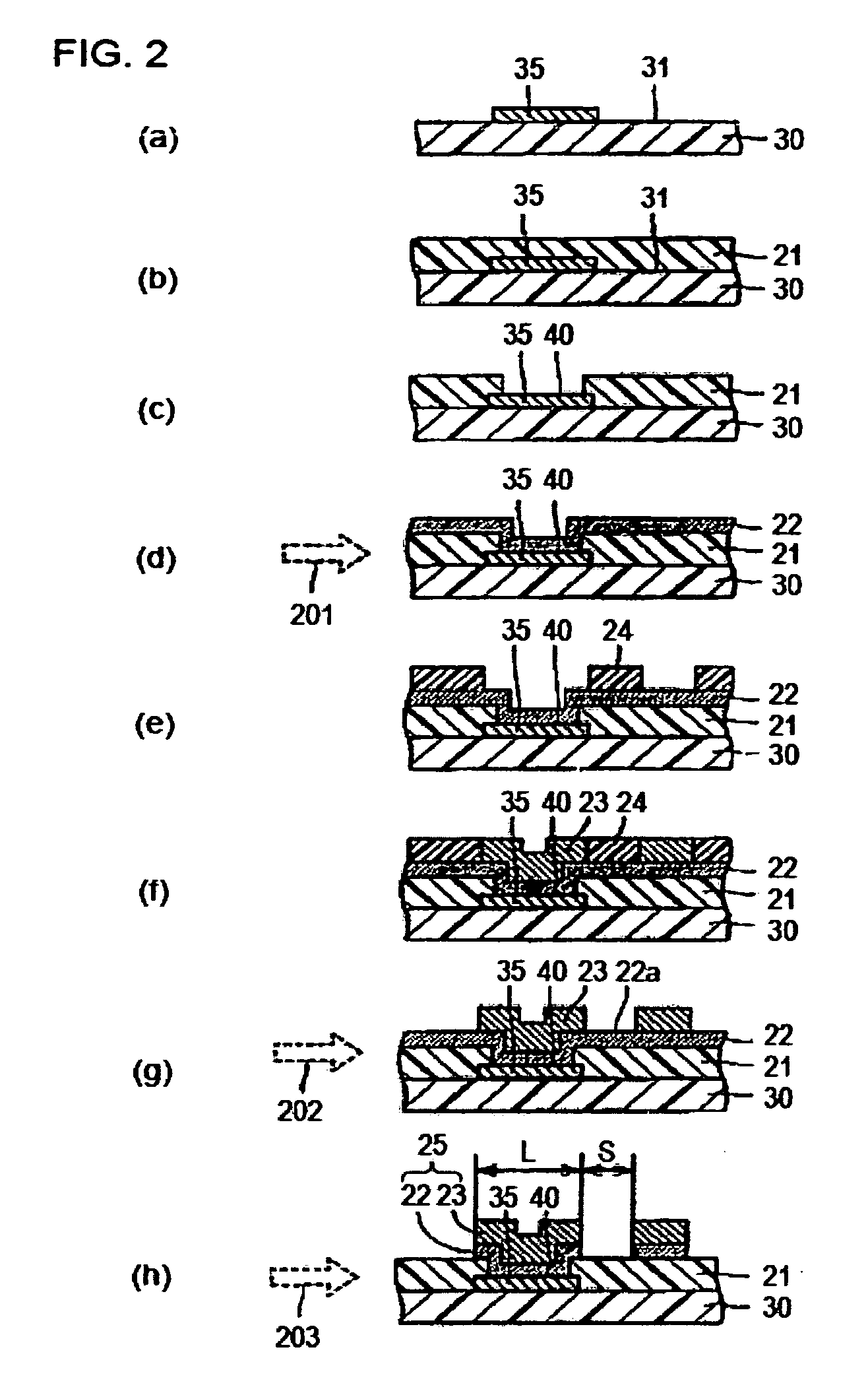

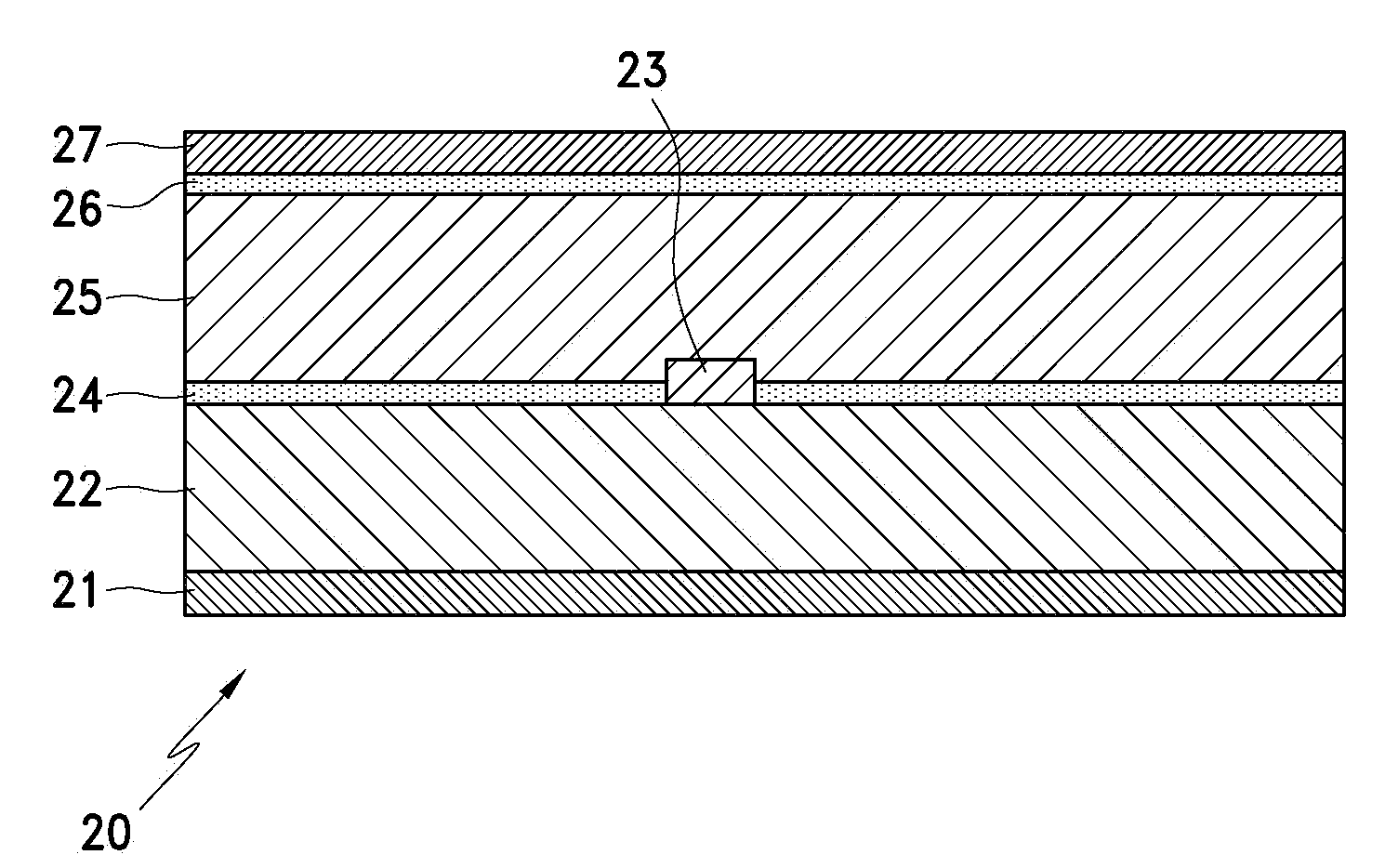

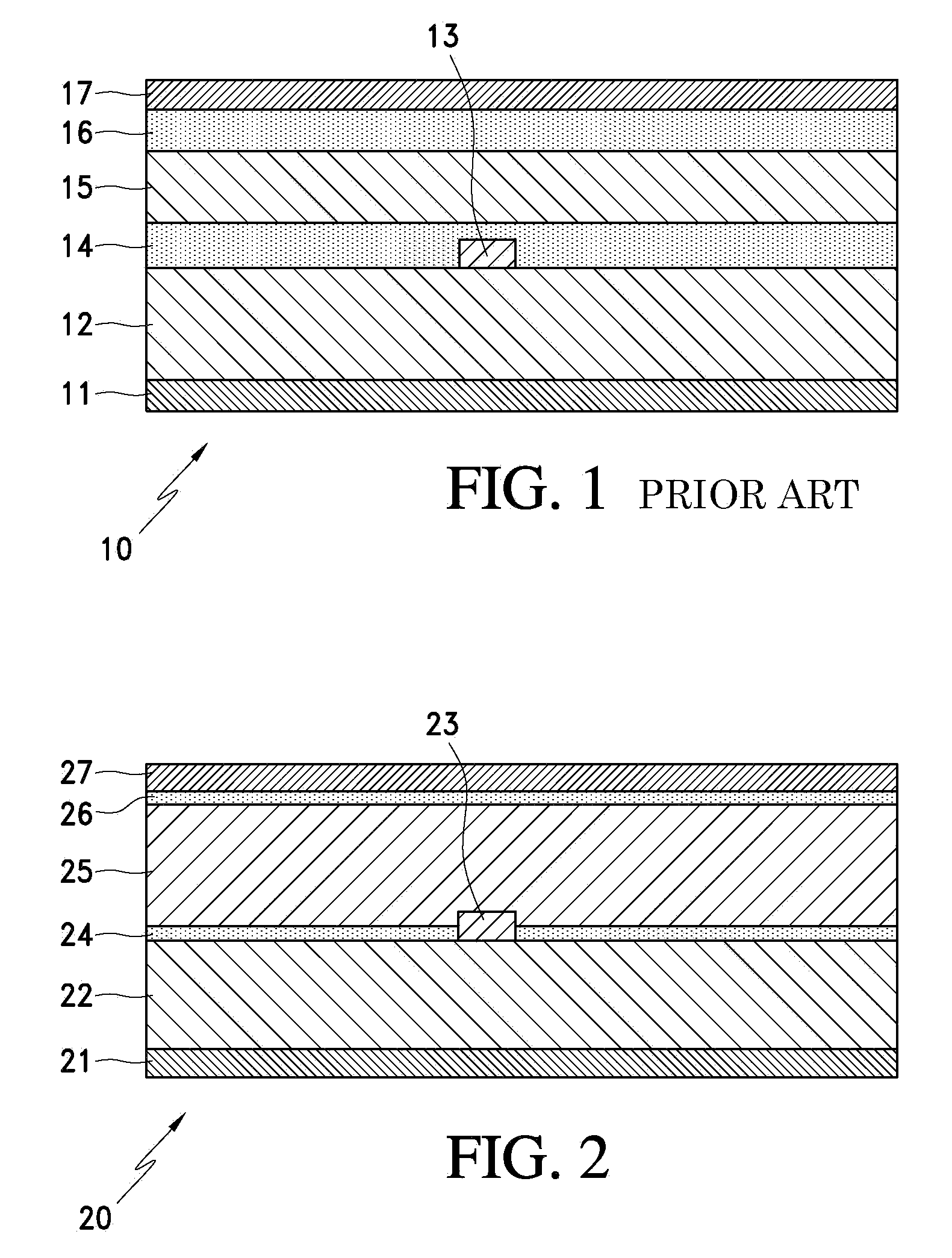

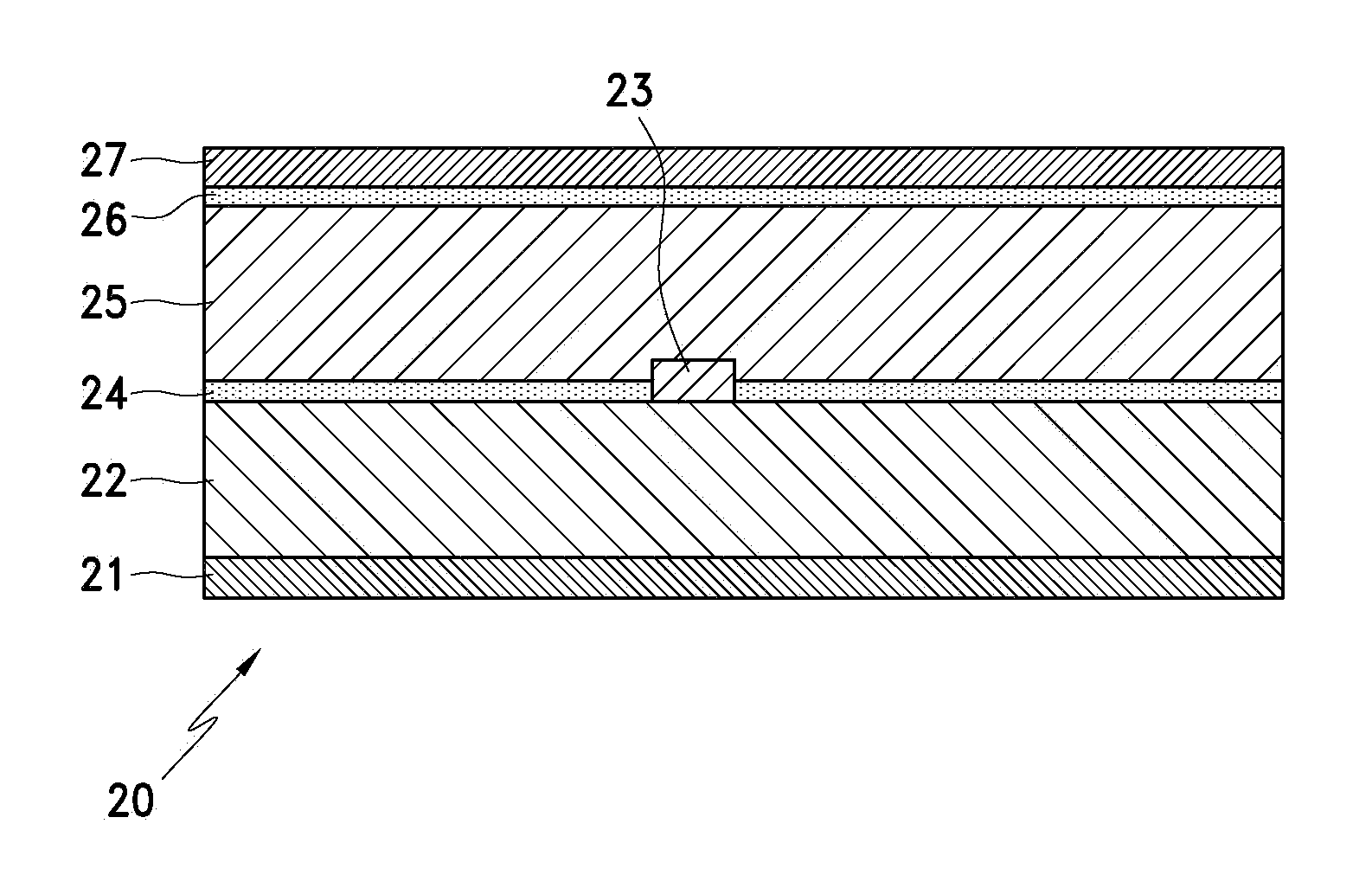

Flexible Printed Circuit Assembly With Reduced Dielectric Loss

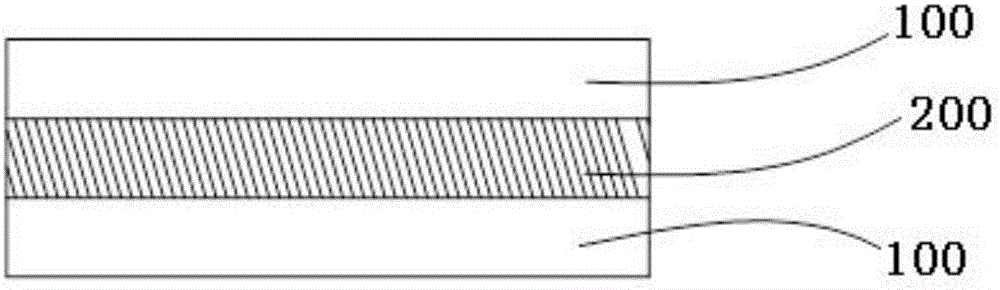

InactiveUS20090211792A1Reduces dielectric lossReduce assembly thicknessPrinted circuit assemblingDielectric materialsDielectric lossFluorocarbon

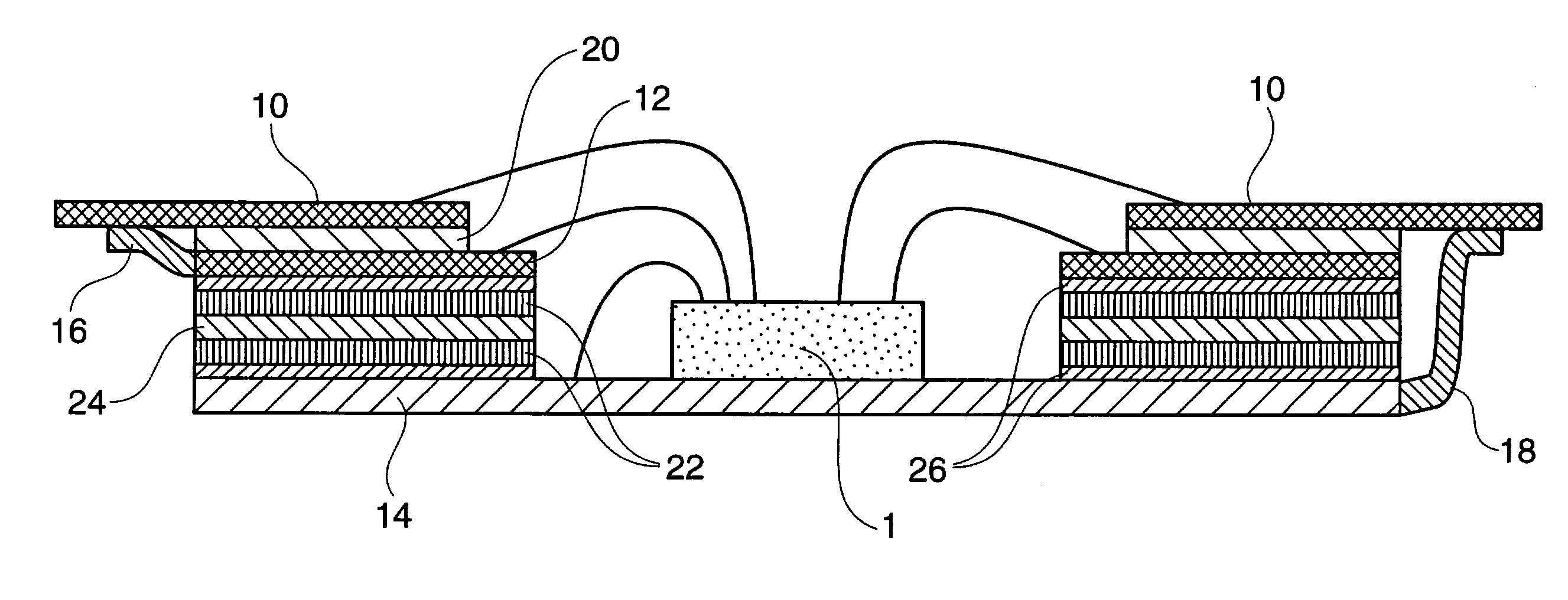

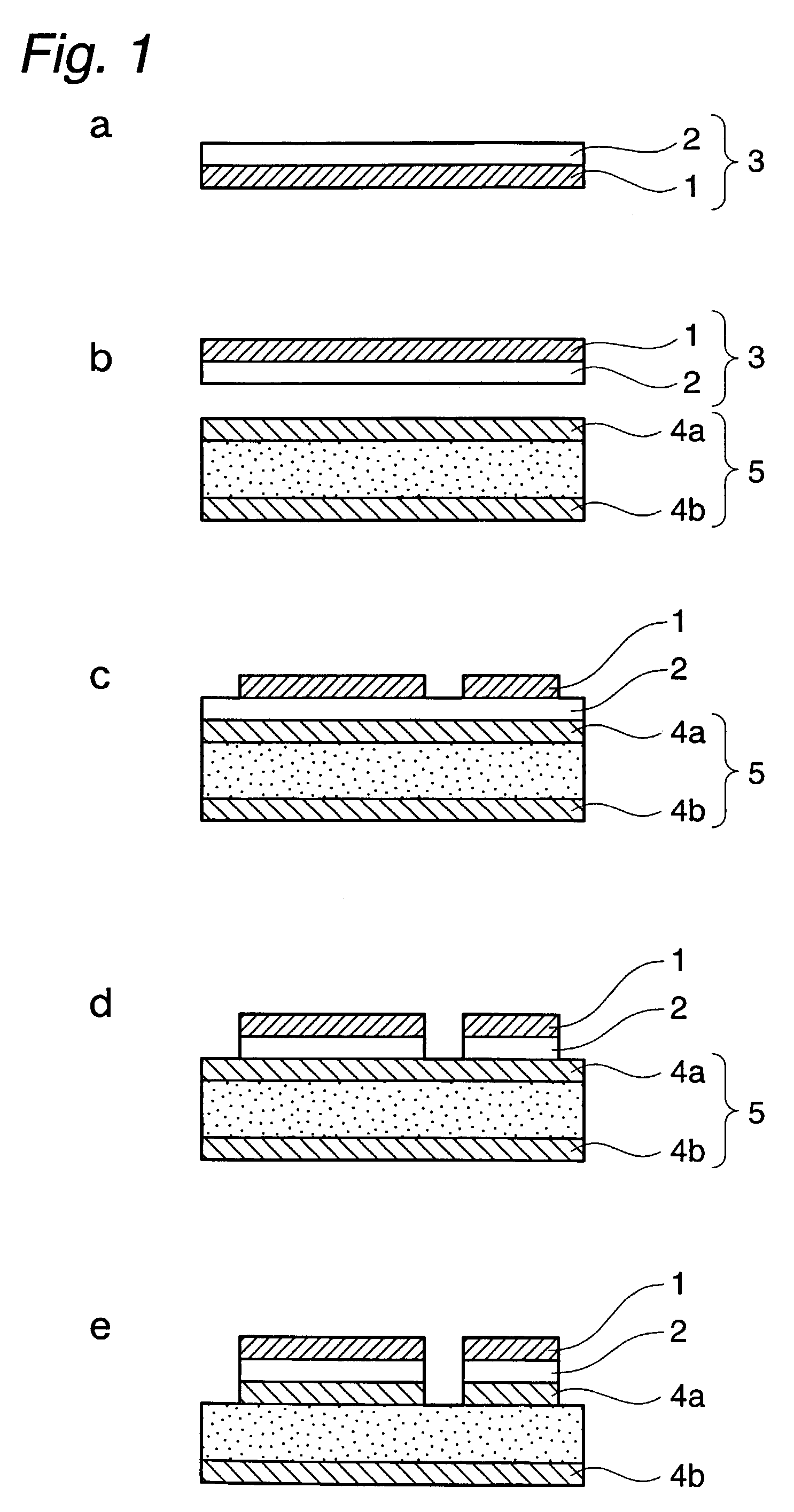

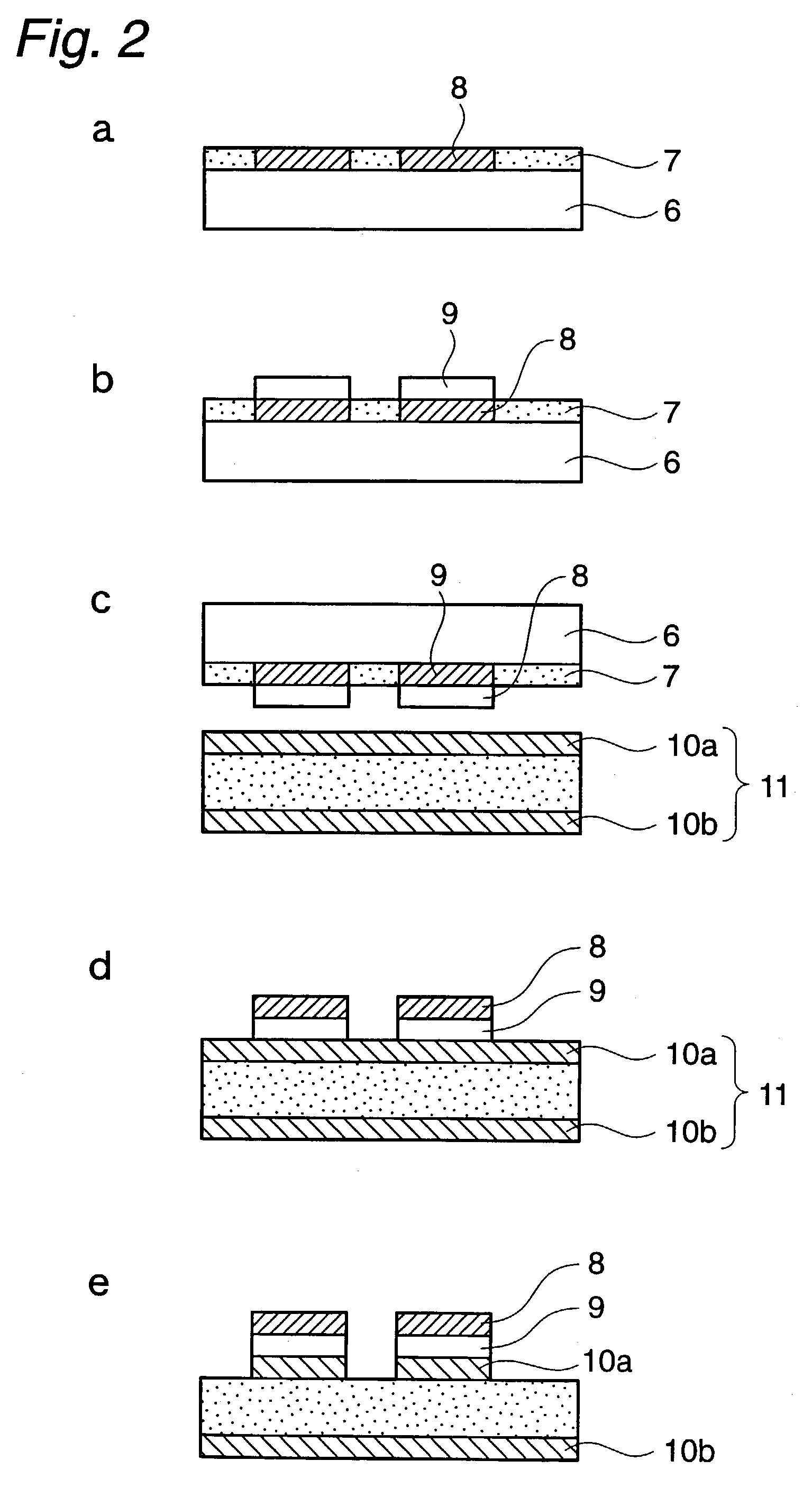

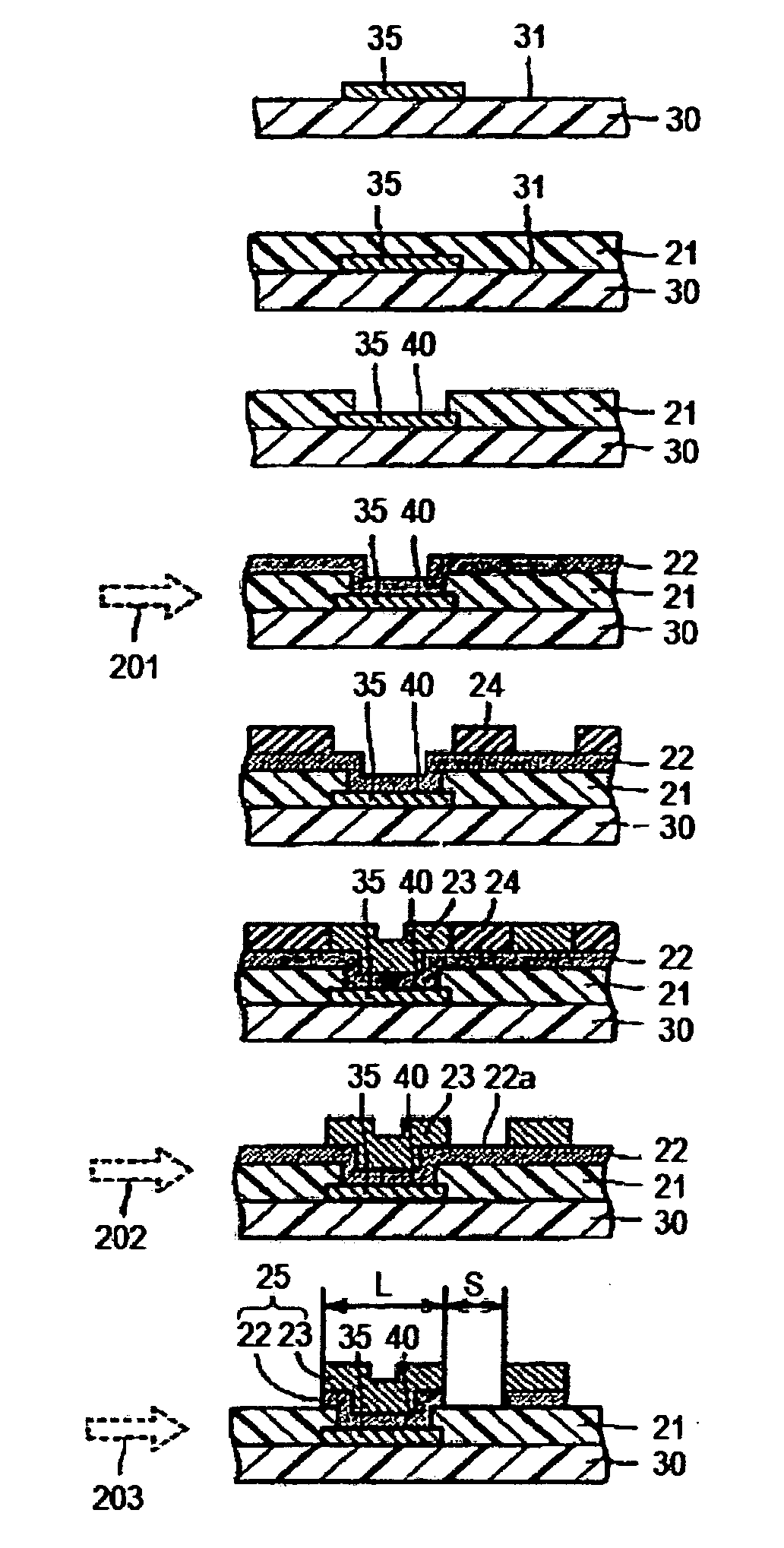

A flexible printed circuit assembly with a fluorocarbon dielectric layer and an adhesive layer with reduced thickness. The flexible printed circuit assembly includes a first dielectric layer and a signal trace disposed on the first dielectric layer. An adhesive layer with a thickness smaller than a height of the signal trace is disposed on the first dielectric layer, so that only a portion of a side surface of the signal trace is covered. A second dielectric layer made of fluorocarbon is disposed on the adhesive layer, covering a remaining portion of the side surface of the signal trace and a top surface of the signal trace.

Owner:IBM CORP +1

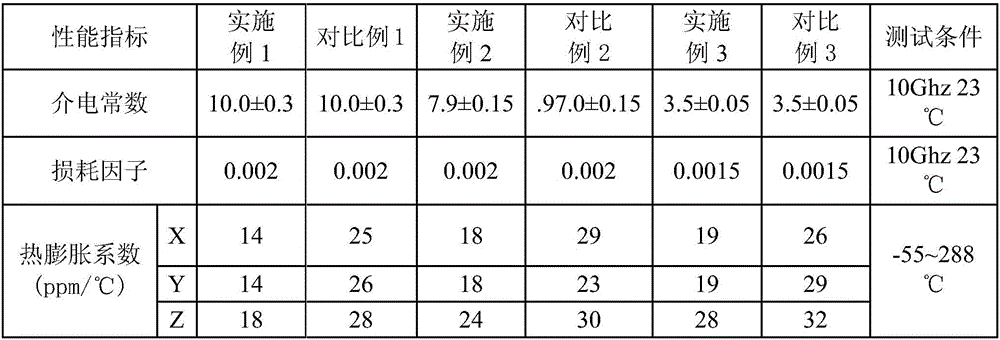

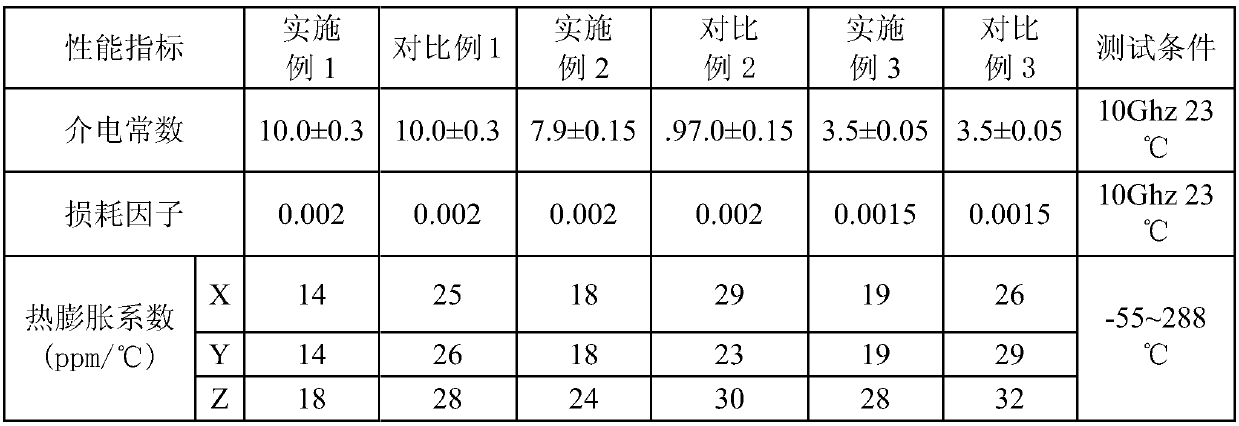

Composite microwave dielectric material, printed circuit board base material made of composite microwave dielectric material and manufacturing method of composite microwave dielectric material

ActiveCN106800733ASmall coefficient of thermal expansionSmall dielectric loss tangentDielectric materialsCircuit susbtrate materialsThermal expansionPrinted circuit board

The invention discloses a composite microwave dielectric material. The composite microwave dielectric material is prepared from the following components in parts by weight: 25 to 35 parts of a fluorine-containing polymer and 20 to 70 parts of microwave dielectric ceramic powder. According to the composite microwave dielectric material, fluororesin is adopted as a carrier material and blended with the microwave dielectric ceramic powder, and the dielectric loss angle tangent of a composite material and a high-frequency circuit substrate can be reduced; a radiation crosslinking technology is adopted to perform crosslinking processing on the fluorine-containing polymer to further reduce the coefficient of thermal expansion of the material; the expansion factor of a printed circuit board base material is close to the expansion factor of hole copper; the circuit fault problem in the process of use are avoided; and the irradiation crosslinking also improves the mechanical performance of the printed circuit board base material.

Owner:上海安缔诺科技有限公司

Resin composition and molded article using the same

ActiveUS8025814B2Improve featuresSmall dielectric loss tangentLiquid crystal compositionsRadiating elements structural formsPolymer sciencePolymer chemistry

The present invention provides a resin composition comprising a liquid crystal polymer and a filler comprising a composite oxide containing Ba, Sm, and Ti. The resin composition can provide a molded article which has excellent dielectric characteristics and is excellent in dimension stability.

Owner:SUMITOMO CHEM CO LTD

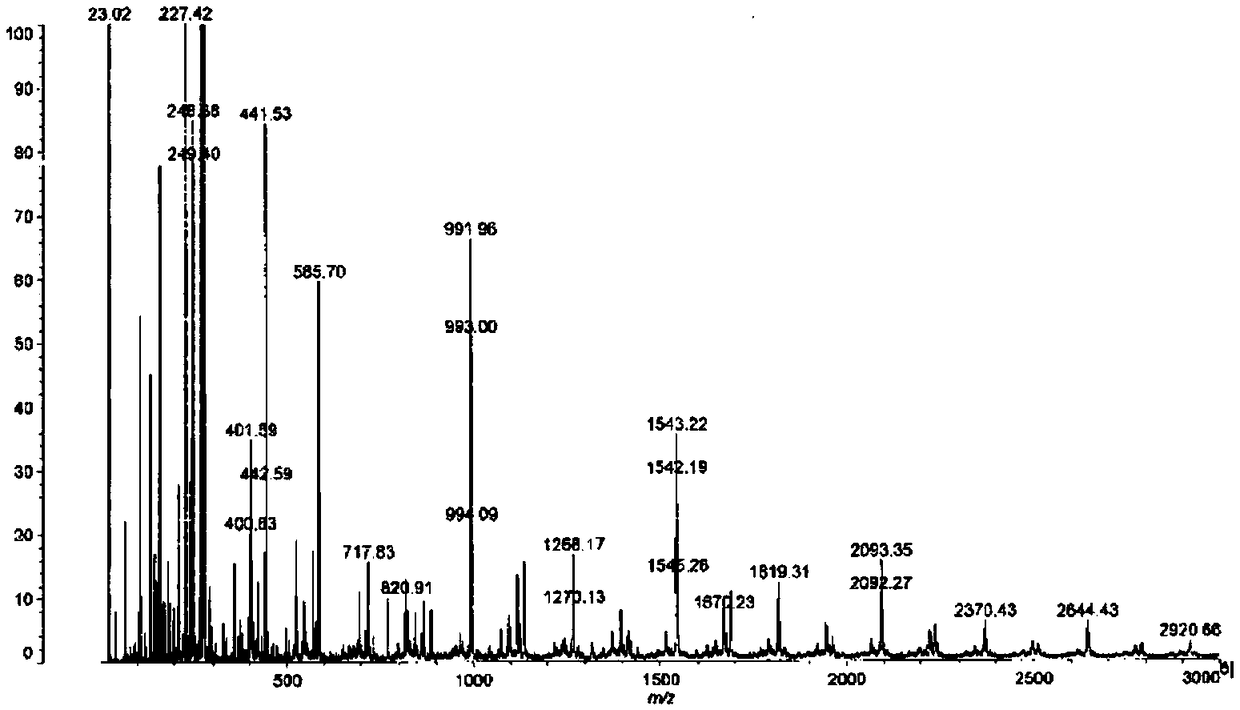

Nonaqueous dispersion of fluorine-based resin heat cure resin composition containing fluorine-based resin using same and the cured product thereof polyimide precursor solution composition

ActiveCN107434944ASuppression of decrease in adhesion strengthSuppression of decrease in adhesive strengthEpoxy resin coatingsSolventAdhesion strength

The present invention provides a non-aqueous dispersion of a fluorine-based resin, a thermosetting resin composition containing the fluorine-based resin using the same, a polyimide precursor solution composition and the like, which have a particle diameter, and excellent preservation stability, can be mixed with a resin material such as a thermosetting resin composition, and can inhibit a decrease in adhesion strength and adhesive strength while achieving a low dielectric constant and a low dielectric tangent to be suitably used for applications such as an insulating layer of a printed wiring board, an adhesive for a circuit board, a laminate for a circuit board, a coverlay film, a prepreg, and the like. The nonaqueous dispersion of a fluorine-based resin comprises a micropowder of at least a fluorine-based resin, urethane fine particles, a fluorine-based additive containing at least a fluorine group and a lipophilic group, and a non-aqueous solvent.

Owner:MITSUBISHI PENCIL CO LTD

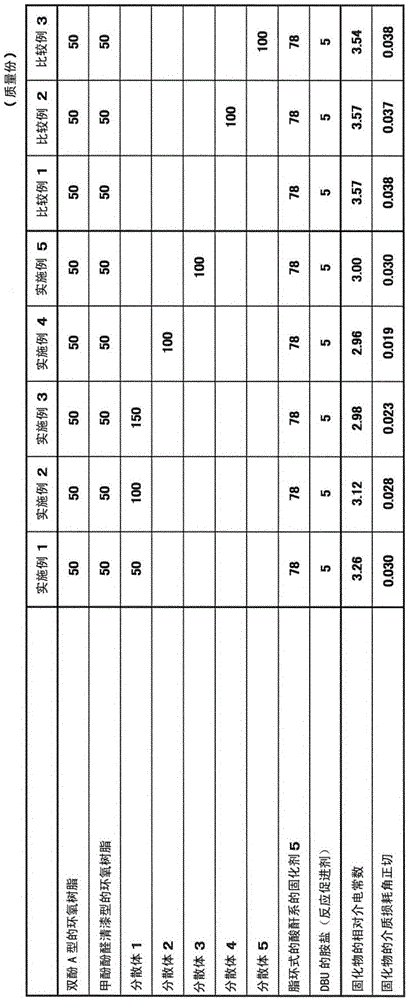

Epoxy resin composition and cured product thereof

ActiveCN106795259AHigh thermal conductivityImprove flame retardant performanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyDielectric loss

In the present invention, a triazine ring-containing phenolic resin, which is obtained by reacting melamine, a para-alkylphenol, and formalin, is used in order to provide an epoxy resin composition which imparts a cured product with excellent flame retardancy, exhibits excellent dielectric properties such as low dielectric loss tangent and low dielectric constant, and also exhibits excellent thermal conductivity, a cured product of the epoxy resin composition, and the following which use the expoxy resin composition: a prepreg; a circuit board; a build-up film; a build-up substrate; a semiconductor sealing material; a semiconductor device; a fiber-reinforced composite material; a molded article; and the like.

Owner:DIC CORP

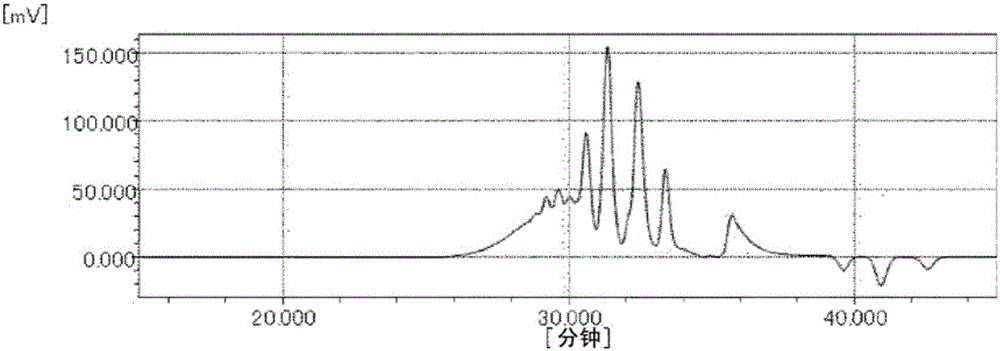

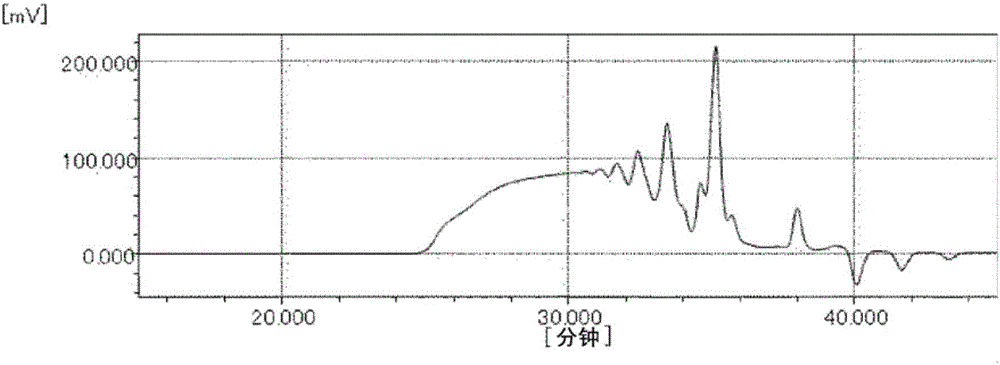

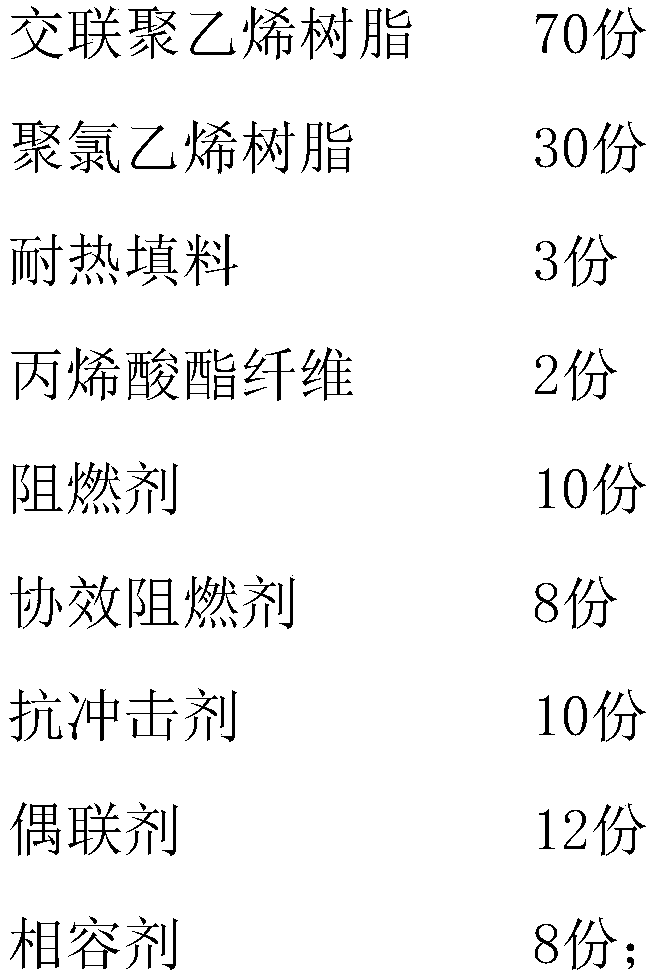

Insulating material with high heat resistance and preparation method thereof as well as prepared cable protection pipe

The invention relates to the technical field of cable protection pipe materials, in particular to an insulating material with high heat resistance and a preparation method thereof as well as a prepared cable protection pipe. The insulating material with high heat resistance is prepared from the following raw materials in parts by weight: 70 to 90 parts of crosslinked polyethylene resin, 30 to 60 parts of polyvinyl chloride resin, 3 to 8 parts of a heat-resisting filler, 2 to 6 parts of an acrylic ester fiber, 10 to 12 parts of a flame retardant, 8 to 12 parts of a synergistic flame retardant,10 to 12 parts of an impact resisting agent, 12 to 15 parts of a coupling agent and 8 to 16 parts of a compatilizer, wherein the heat-resisting filler is a mixture prepared from calcium carbonate, lignocelluloses and magnesium silicide according to the weight ratio of (3 to 8): (2 to 6): (1.5 to 2). The insulating material with the high heat resistance is relatively high in insulating resistance and high in loading capacity by crosslinking and polymerizing the crosslinked polyethylene resin and the polyvinyl chloride resin, has relatively high properties such as heat resistance, flame retardancy and impact resistance, and is good in mechanical property.

Owner:广东威立瑞科技有限公司

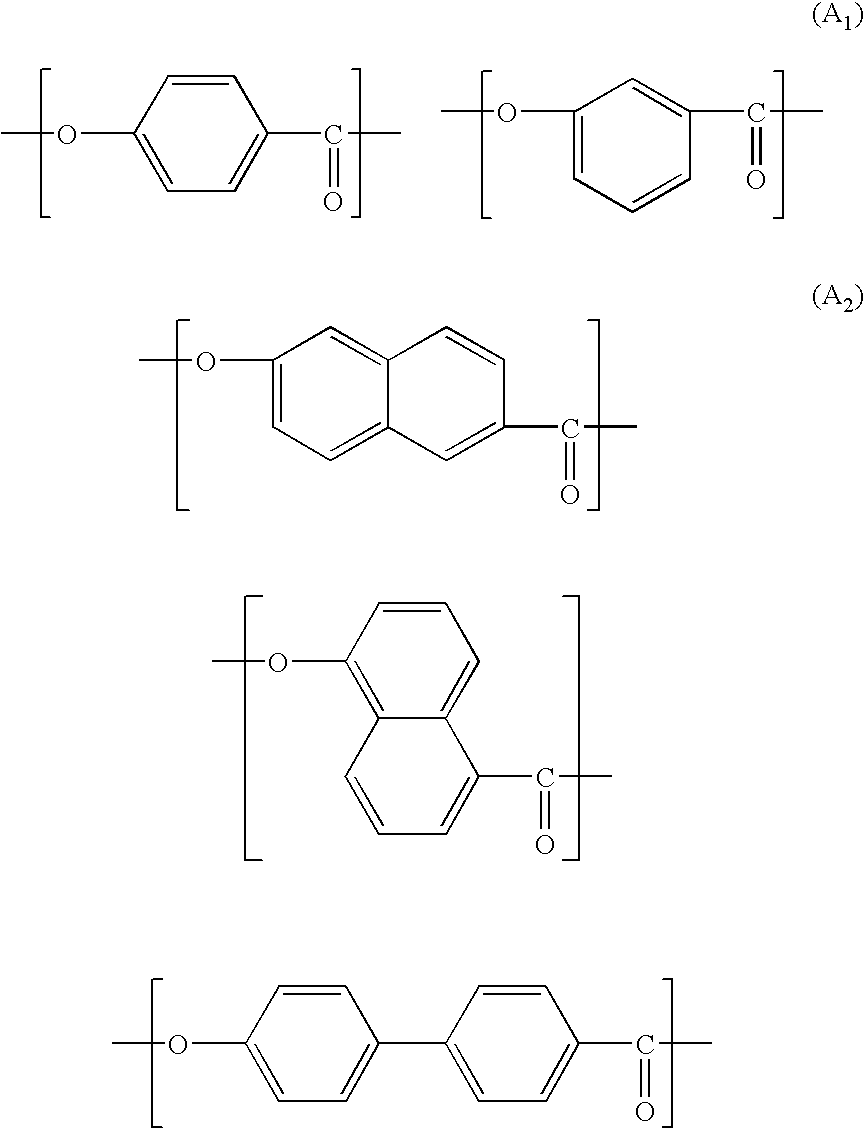

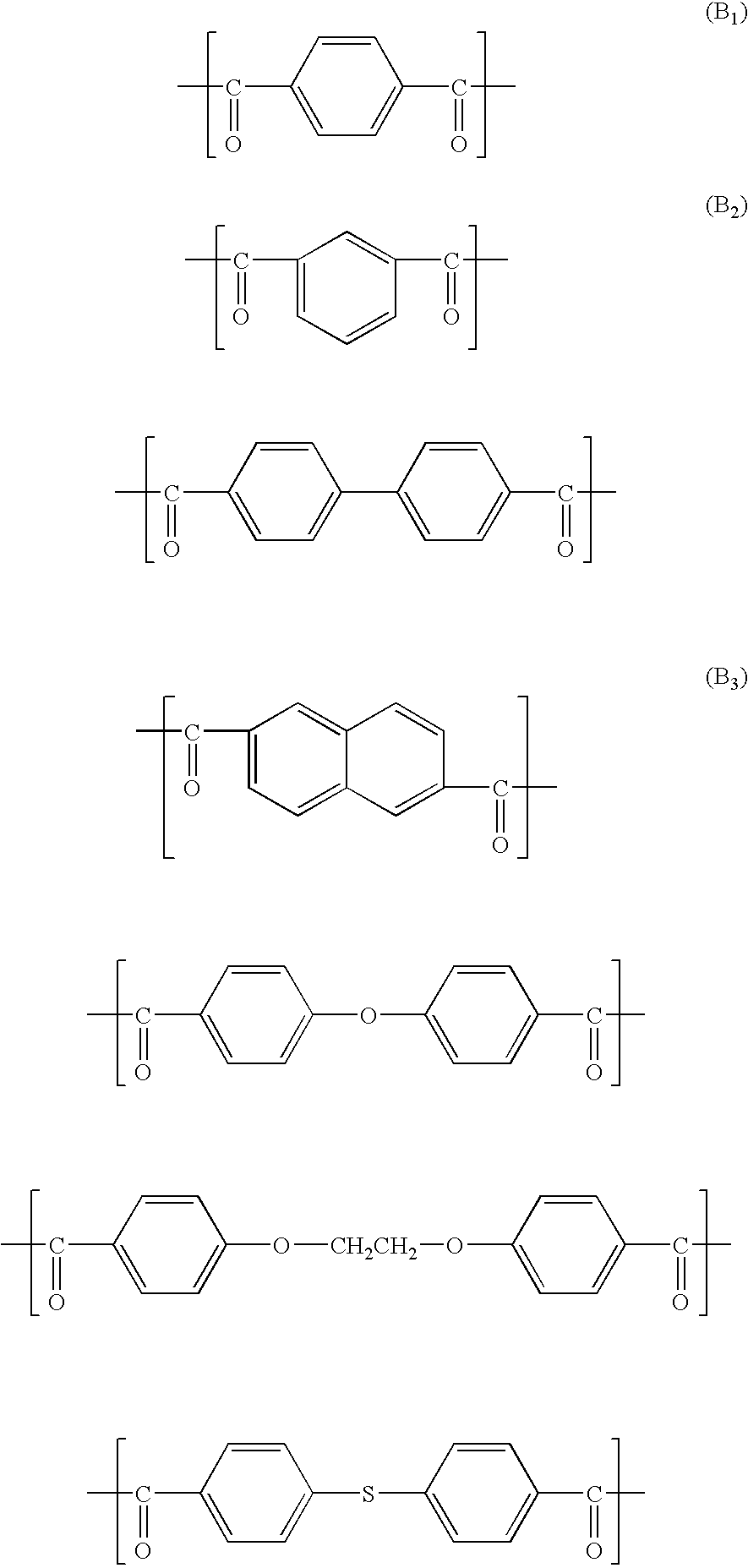

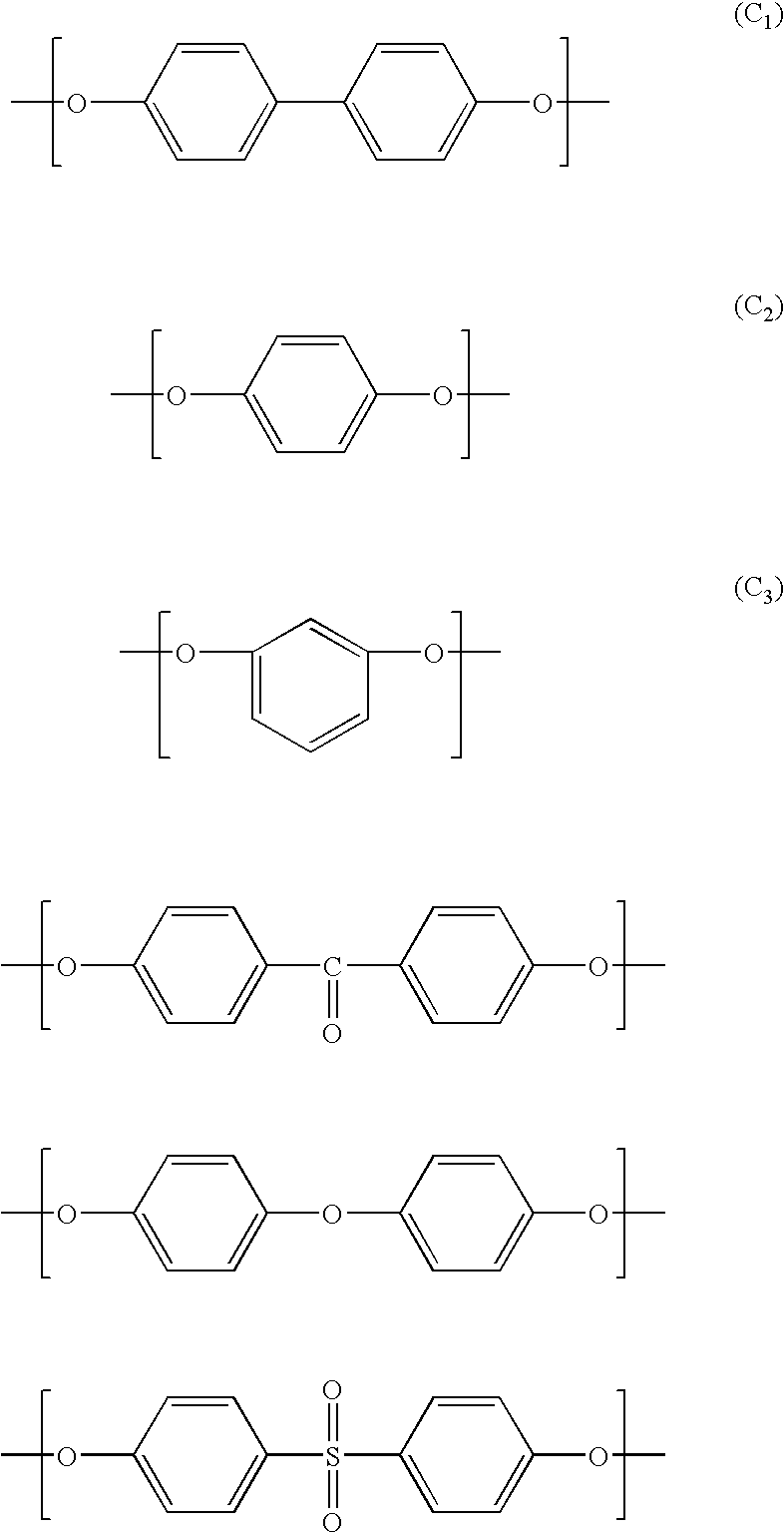

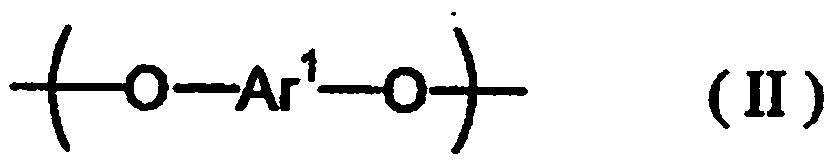

Wholly aromatic liquid crystal polyester resin, molded article, and electrical/electronic component

ActiveCN109563253AHigh melting pointReduce qualityPlastic/resin/waxes insulatorsInsulating bodiesPolymer scienceDielectric loss

To provide a wholly aromatic liquid crystal polyester resin that exhibits excellent heat resistance while having an extremely low dielectric loss tangent. This wholly aromatic liquid crystal polyesterresin is characterized by containing constituent units (I) derived from 6-hydroxy-2-naphthoic acid, constituent units (II) derived from an aromatic diol compound, and constituent units (III) derivedfrom an aromatic dicarboxylic acid compound, with the constituent units (III) containing constituent units (IIIA) derived from terephthalic acid and further containing at least one type selected fromamong constituent units (IIIB) derived from 2,6-naphthalenedicarboxylic acid and constituent units (IIIC) derived from isophthalic acid, and with the compositional ratios of the constituent units satisfying the following conditions: 40 mol.% <=constituent unit (I) <= 80 mol.% 10 mol.% <= constituent unit (II) <= 30 mol.% 3 mol.% <= constituent unit (IIIA) <= 28 mol.% 0 mol.% <= constituent unit (IIIB) <= 9 mol.% 0 mol.% <= constituent unit (IIIC) < 5 mol.% (However, it is not possible for the quantity of both constituent units (IIIB) and constituent units (IIIC) to be 0 mol.%).

Owner:JXTJ NIPPON OIL & ENERGY CORP

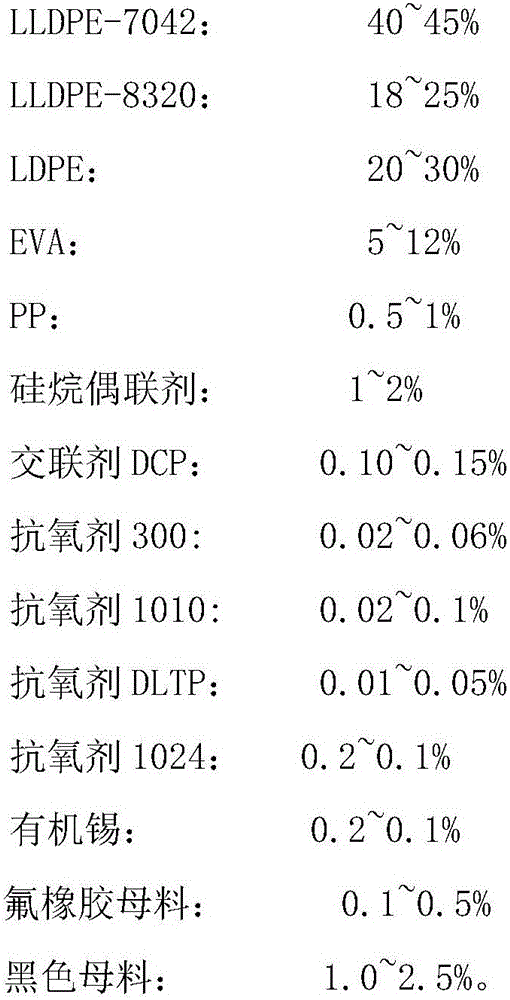

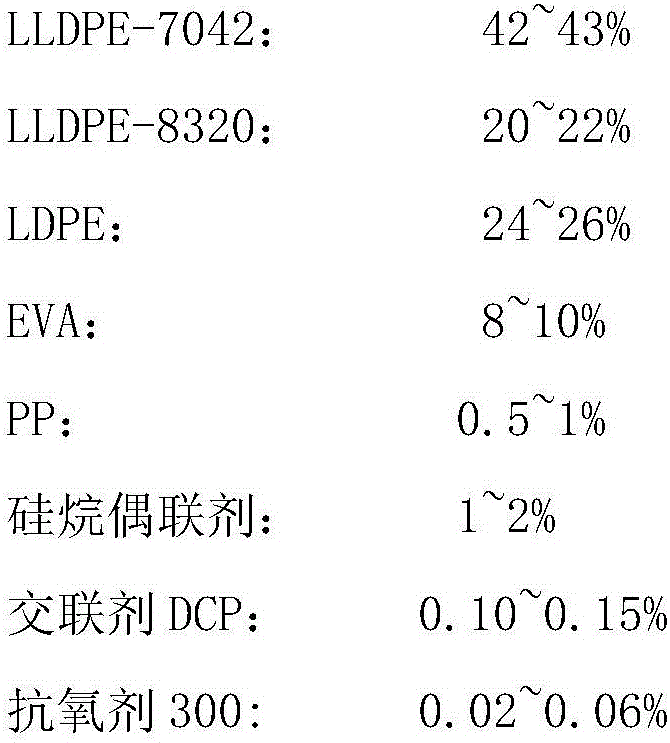

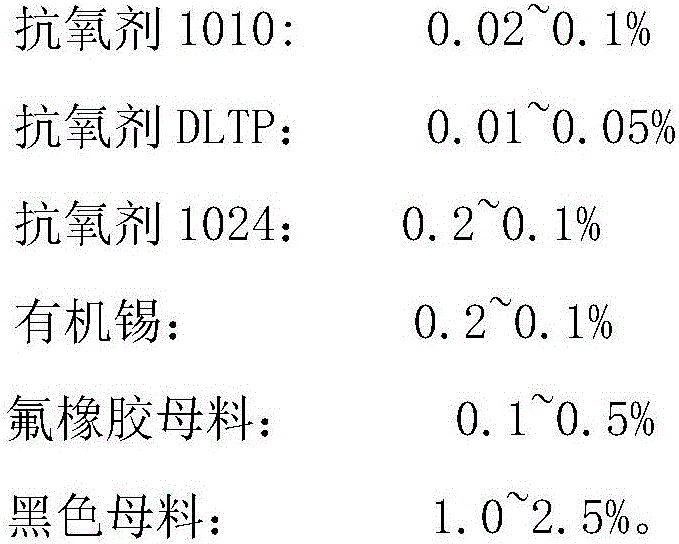

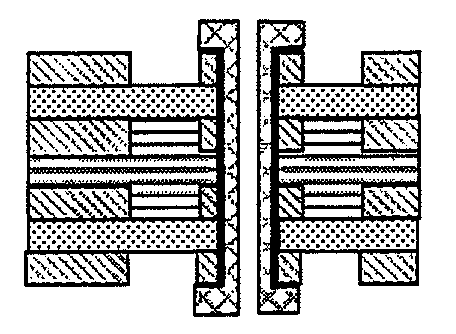

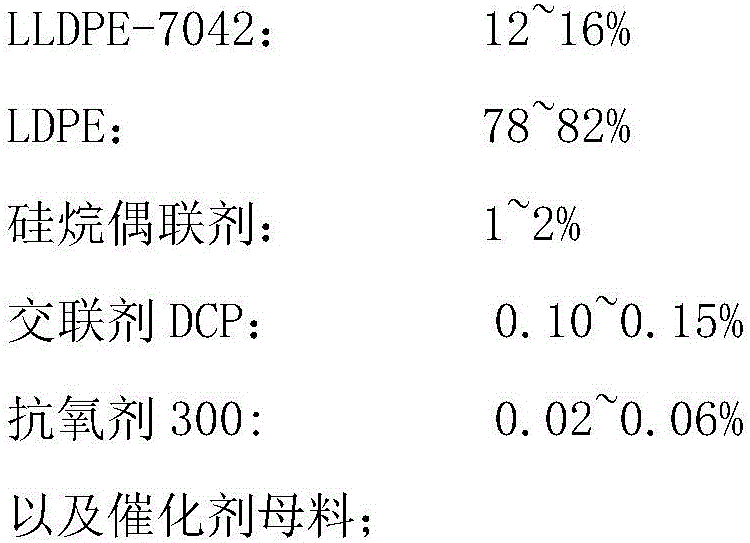

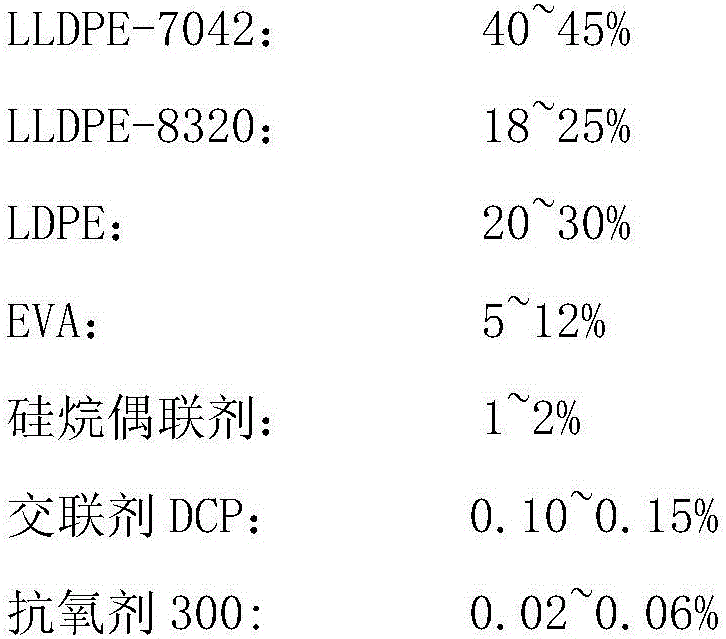

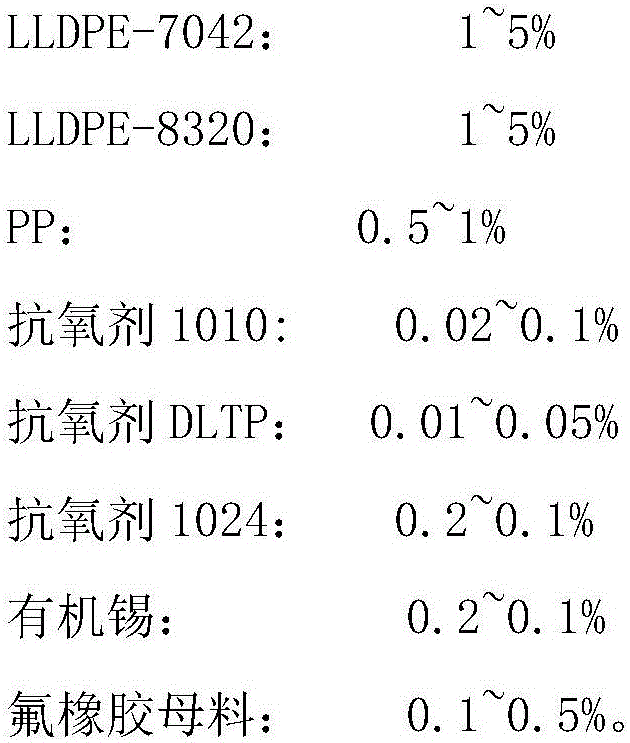

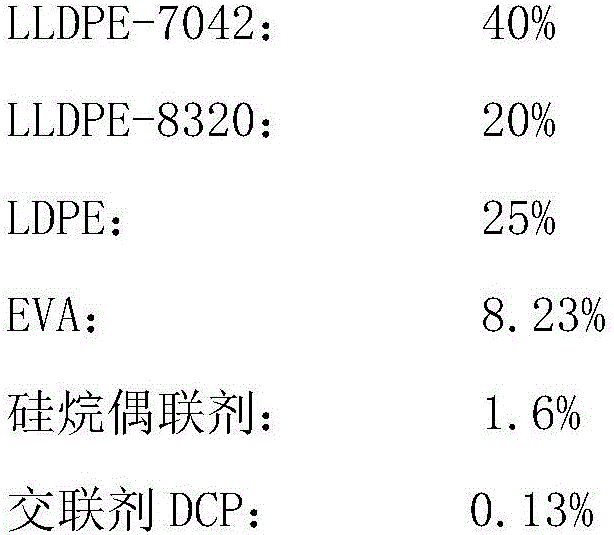

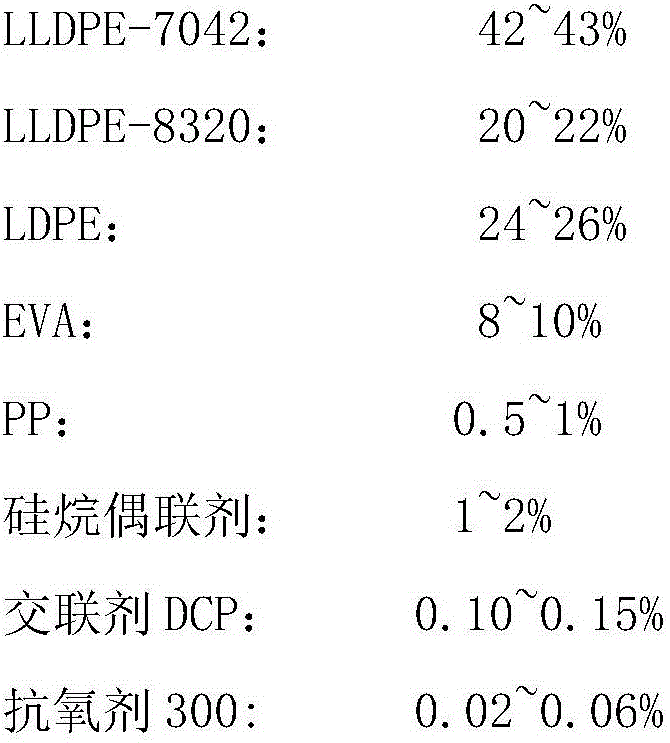

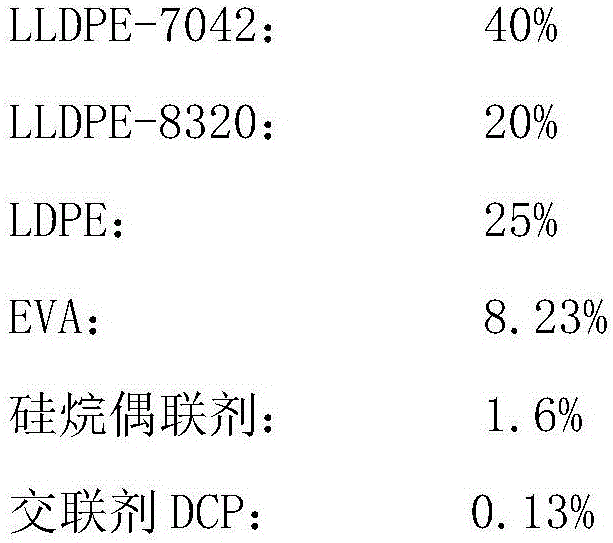

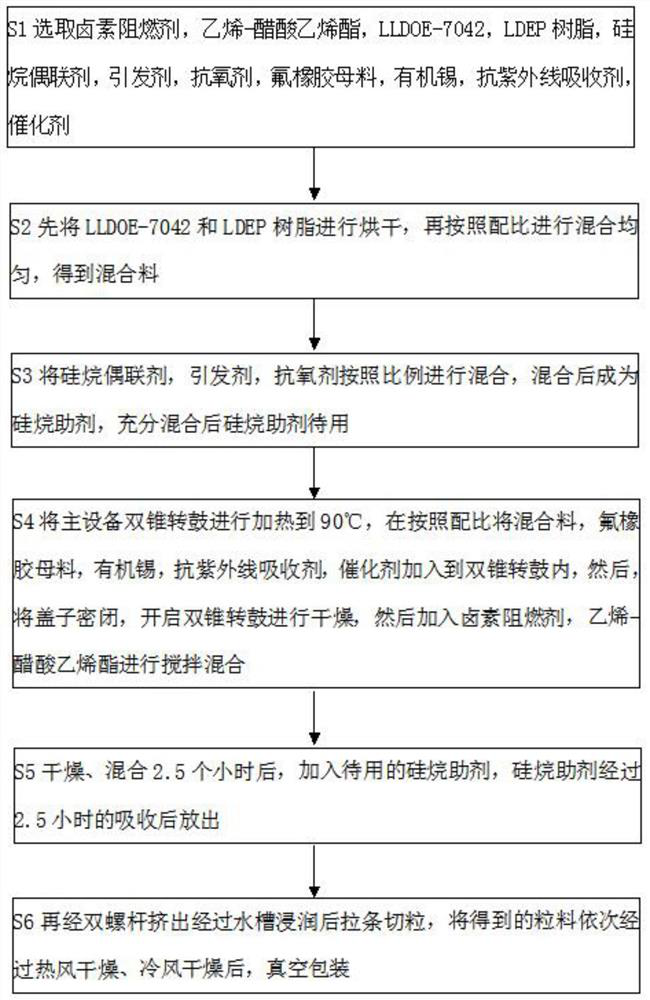

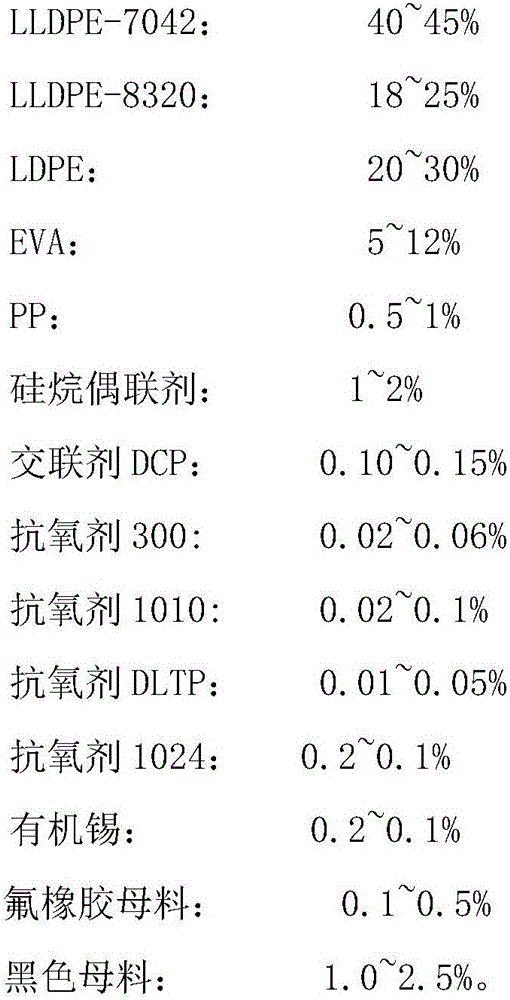

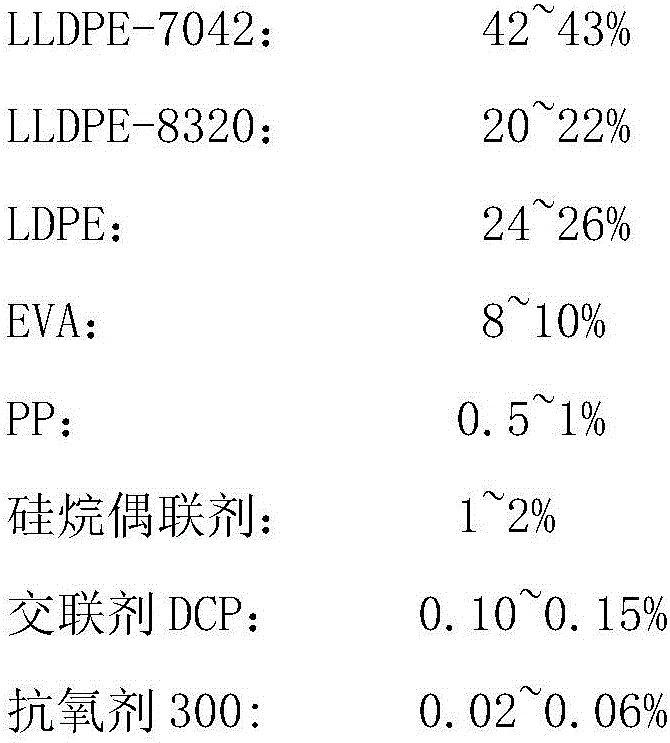

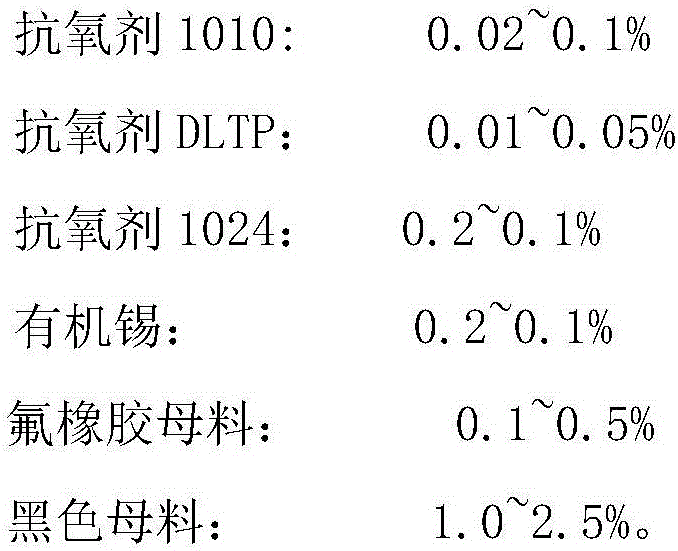

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables through one step

InactiveCN106009224AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsCross-linkSilanes

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below black wires and cables. A method for preparing the insulating material for the 10 kV or below black wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin, fluororubber master batches and black master batches. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

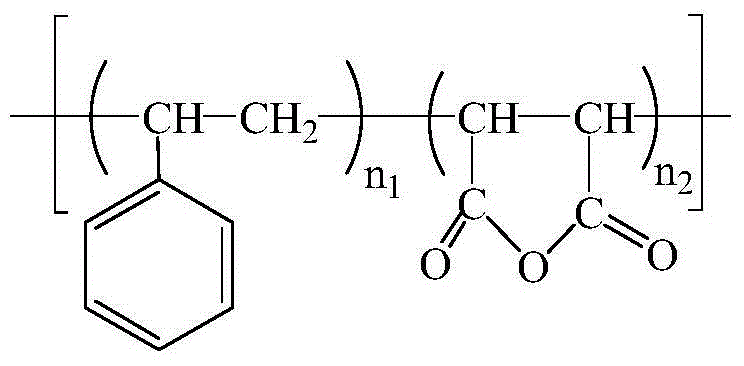

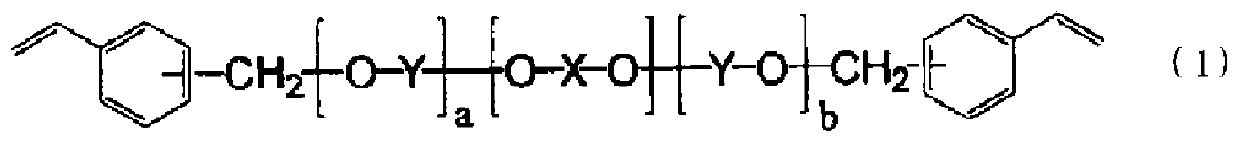

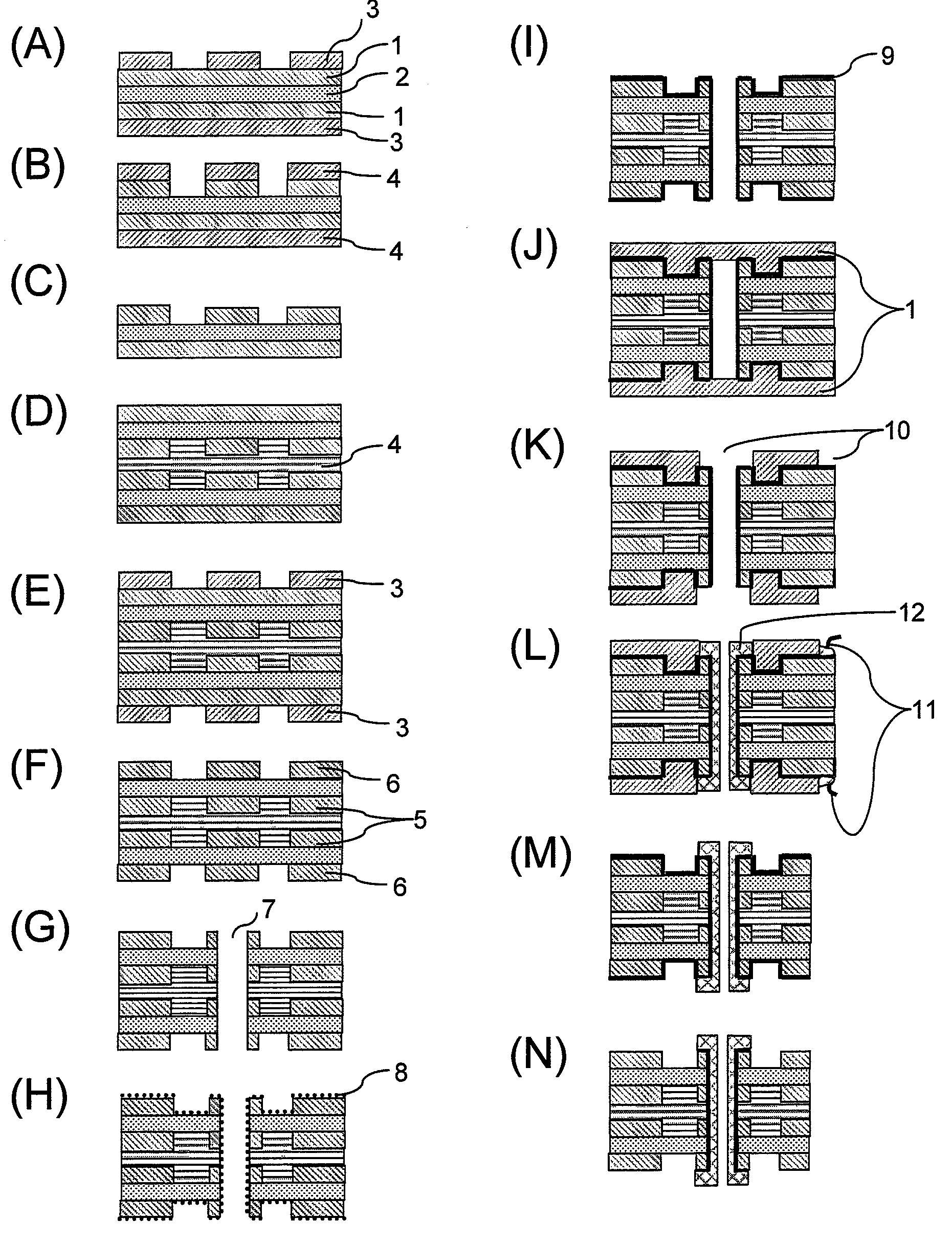

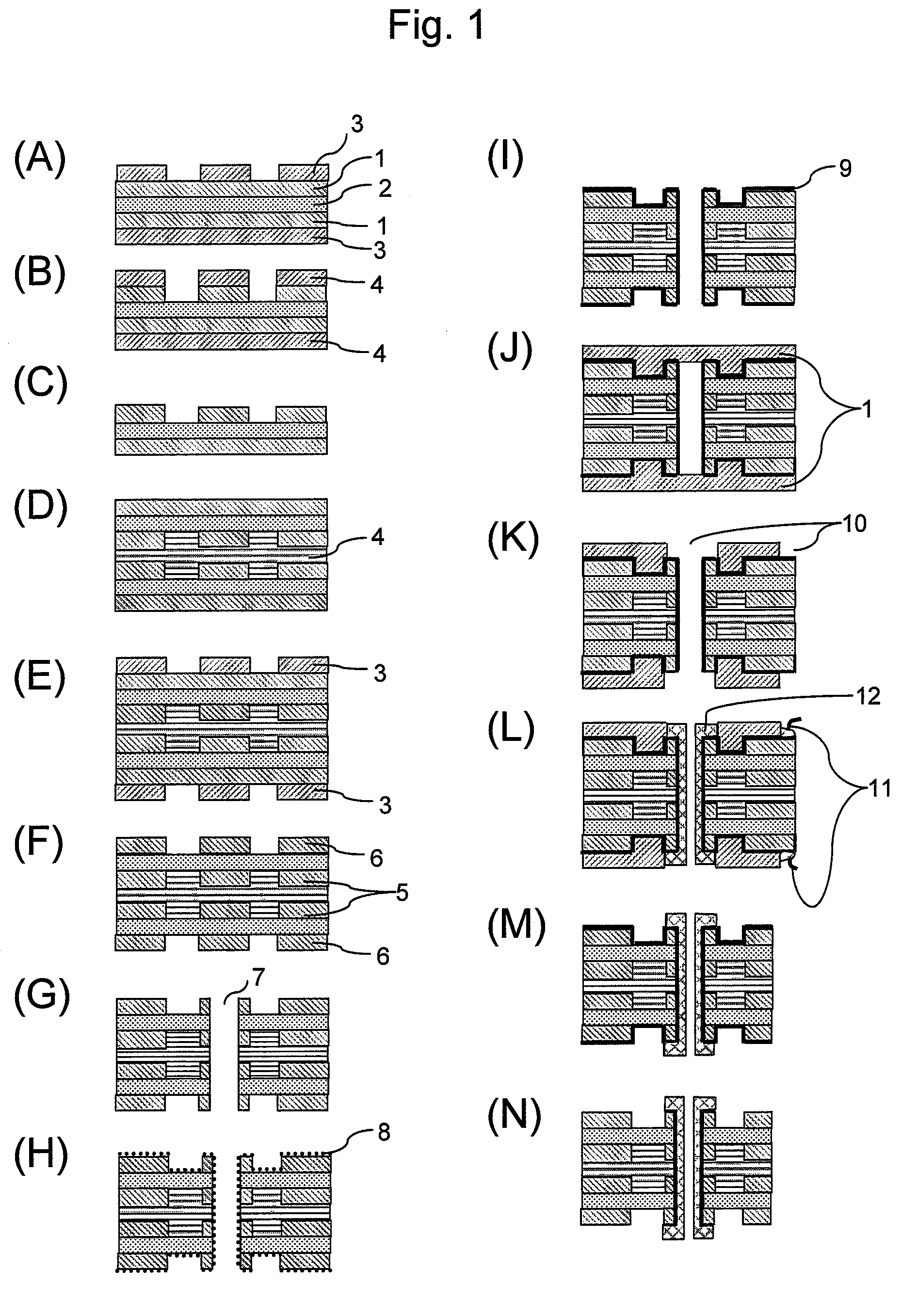

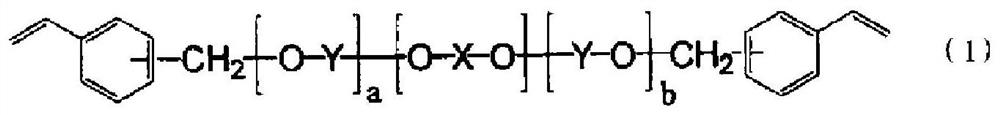

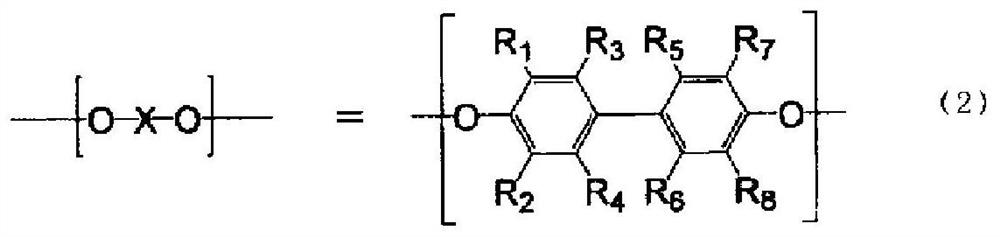

Phase-Separation-Controlled Polybutadiene Resin Composition and Printed Wiring Board Using the Resin Composition

ActiveUS20080090478A1Well formedSmall dielectric constantPrinted circuit aspectsSynthetic resin layered productsHeat resistanceHalf-life

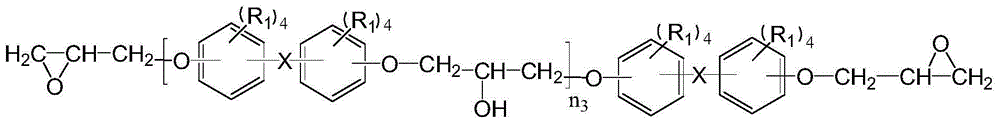

It is an objective of this invention to obtain: a composition superior in processability, dielectric properties, heat resistance, and adhesiveness by controlling phase separation of a 1,2-polybutadiene resin composition without deterioration of dielectric properties exhibited in high-frequency regions; and a multilayer printed wiring board using the same. This invention relates to a polybutadiene resin composition, comprising: a crosslinking component (A) comprising repeating units represented by the following formula (1) and having a number average molecular weight of 1000 to 20000; a radical polymerization initiator (B), the one-minute half-life temperature of which is 80° C. to 140° C.; and a radical polymerization initiator (C), the one-minute half-life temperature of which is 170° C. to 230° C.; wherein 3 to 10 parts by weight of the component (B) and 5 to 15 parts by weight of the component (C) are contained relative to 100 parts by weight of the component (A). The invention also relates to a prepreg, a laminate, and a printed wiring board, which are produced using the same.

Owner:HITACHI CHEM CO LTD

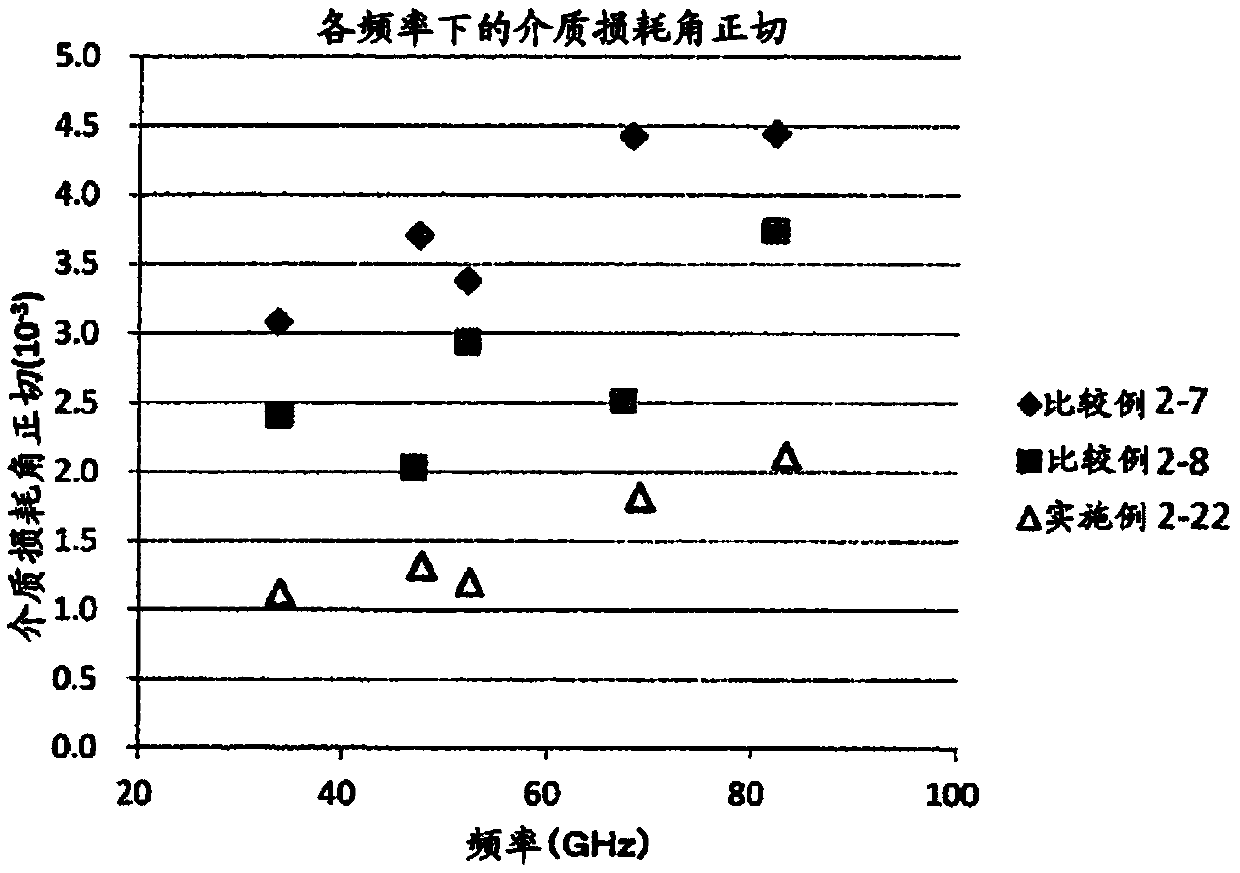

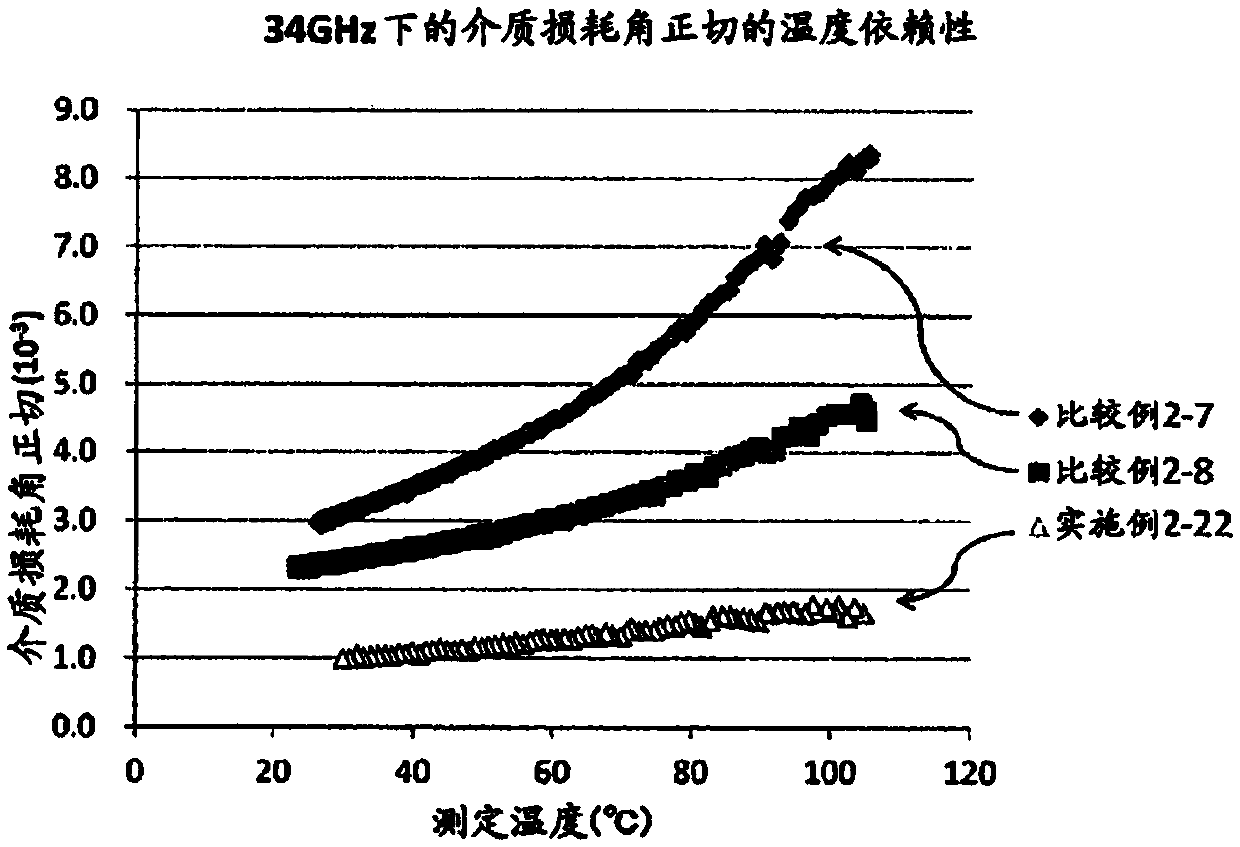

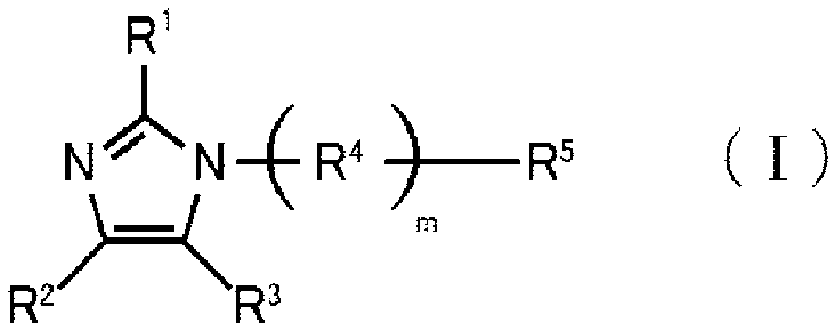

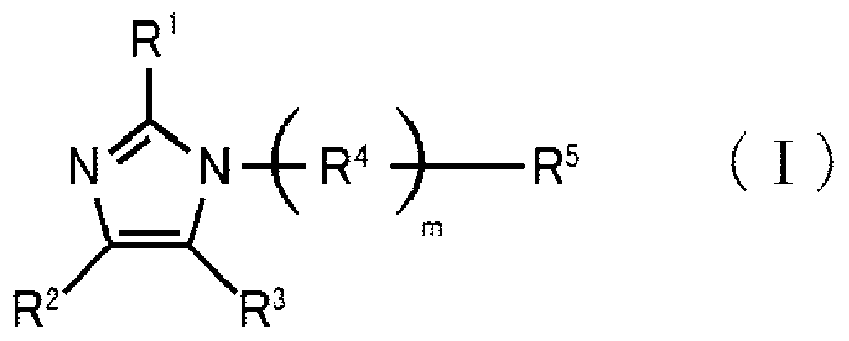

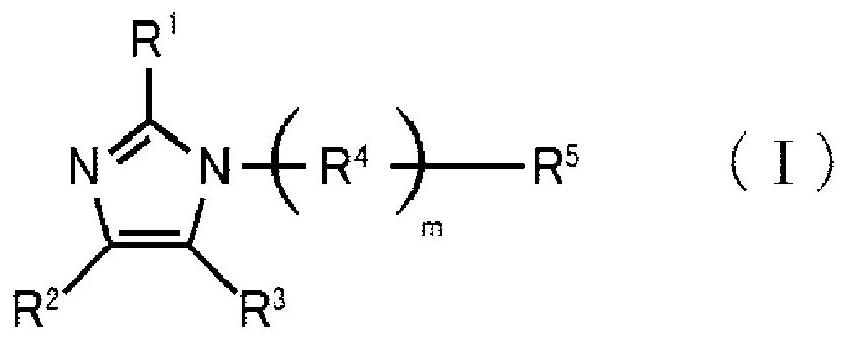

Resin composition, thermosetting film using same, resin cured product, laminate, printed wiring board and semiconductor device

ActiveCN109923176AHigh bonding strengthLow dielectric constantCircuit susbtrate materialsMetal layered productsEpoxySide chain

Provided are: a thermosetting film which has excellent bonding strength to a metal foil contained in wiring lines of a printed wiring board and a substrate material such as a polyimide, while exhibiting dielectric characteristics in a high frequency region, specifically, a low dielectric constant (epsilon) and a low dielectric loss tangent (tan(delta)) in a frequency region of 1-100 GHz; and a resin composition which is used for the production of this thermosetting film. A resin composition which contains (A) an epoxy resin, (B) a resin that has a dielectric loss tangent (tan(delta)) of less than 0.005 in a frequency region of 1-100 GHz and (C) an imidazole compound wherein a side chain having an alkyl group with 5 or more carbon atoms is present at the 1-position of a heterocyclic ring.

Owner:NAMICS CORPORATION

Composite microwave dielectric material, printed circuit board base material made of it and manufacturing method thereof

ActiveCN106800733BSmall coefficient of thermal expansionSmall dielectric loss tangentDielectric materialsCircuit susbtrate materialsExpansion factorMicrowave

The invention discloses a composite microwave dielectric material. The composite microwave dielectric material is prepared from the following components in parts by weight: 25 to 35 parts of a fluorine-containing polymer and 20 to 70 parts of microwave dielectric ceramic powder. According to the composite microwave dielectric material, fluororesin is adopted as a carrier material and blended with the microwave dielectric ceramic powder, and the dielectric loss angle tangent of a composite material and a high-frequency circuit substrate can be reduced; a radiation crosslinking technology is adopted to perform crosslinking processing on the fluorine-containing polymer to further reduce the coefficient of thermal expansion of the material; the expansion factor of a printed circuit board base material is close to the expansion factor of hole copper; the circuit fault problem in the process of use are avoided; and the irradiation crosslinking also improves the mechanical performance of the printed circuit board base material.

Owner:上海安缔诺科技有限公司

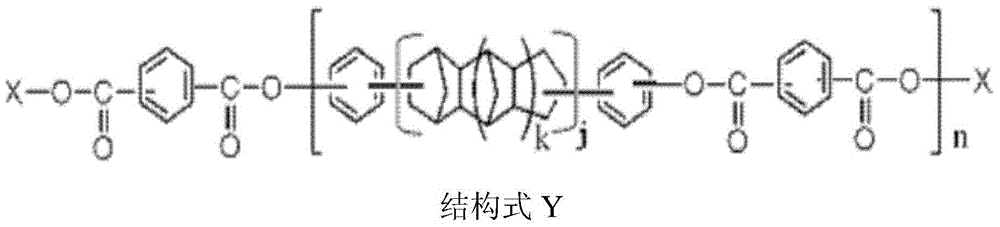

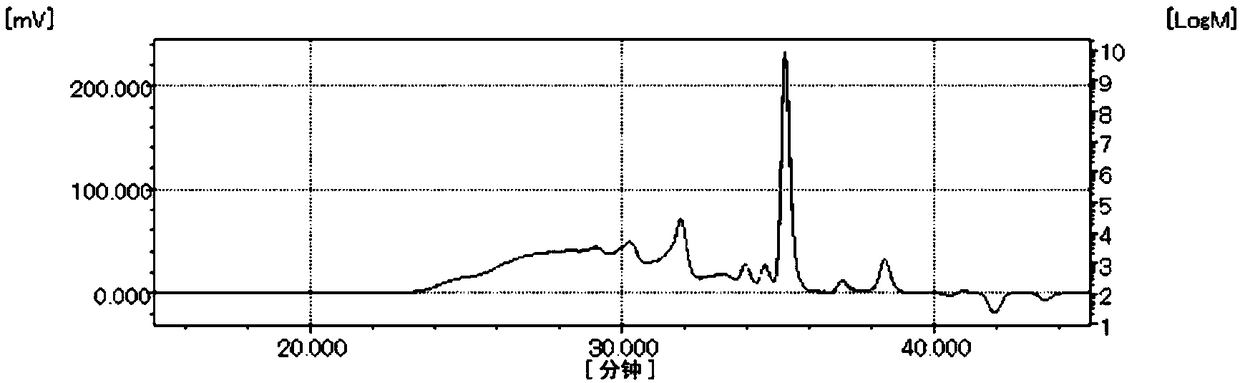

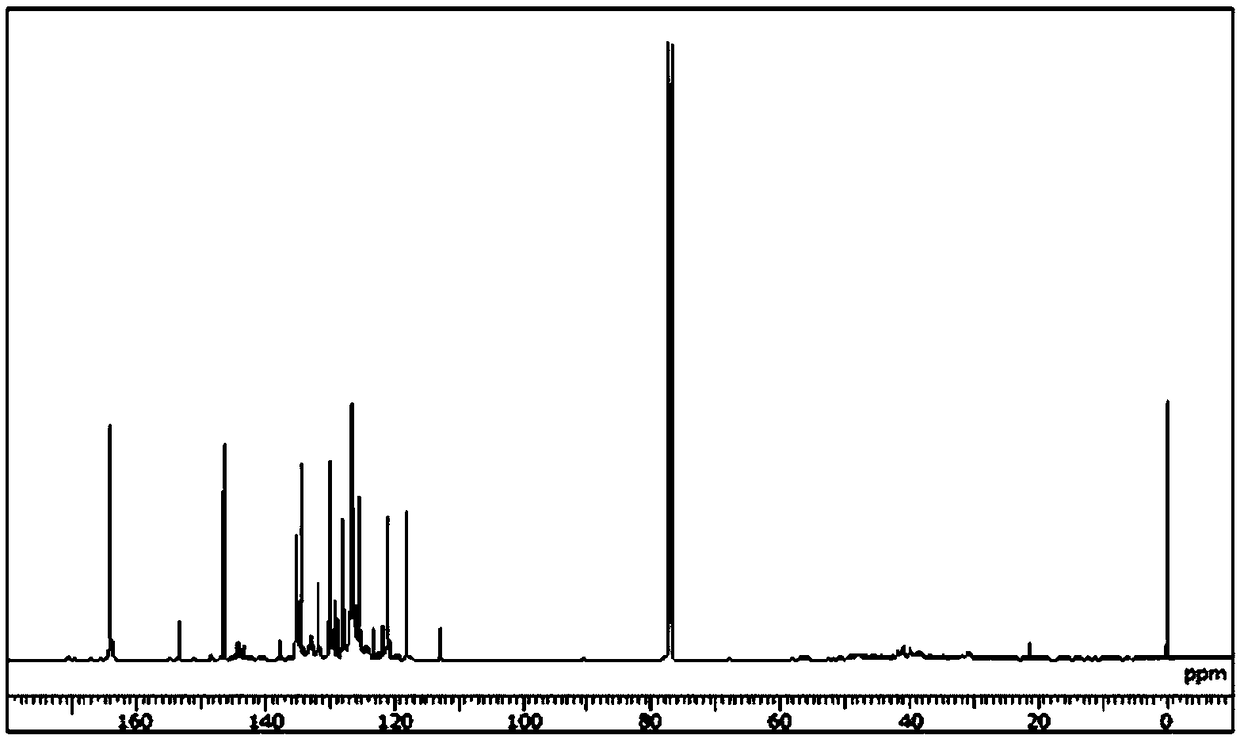

Active ester resin and cured product thereof

ActiveCN109415483ACuring shrinkage is smallSmall dielectric lossSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceSimple aromatic ring

Provided are: an active ester resin having low cure shrinkage and also having a low loss tangent in a cured product; a curable resin composition containing same; a cured product thereof; a printed wiring board; and a semiconductor sealing material. An active ester resin, a curable resin composition containing same, a cured product thereof, a printed wiring board, and a semiconductor sealing material, said active ester resin being characterized by having, as essential reactive raw materials thereof: (A) a phenolic hydroxyl group-containing compound; (B) a polynaphthol resin having a molecular structure whereby a naphthol compound (b) is nodular at a structural site ([alpha]) containing an aromatic ring or a cyclo ring; and (C) an aromatic polycarboxylic acid or an acid halide thereof.

Owner:DIC CORP

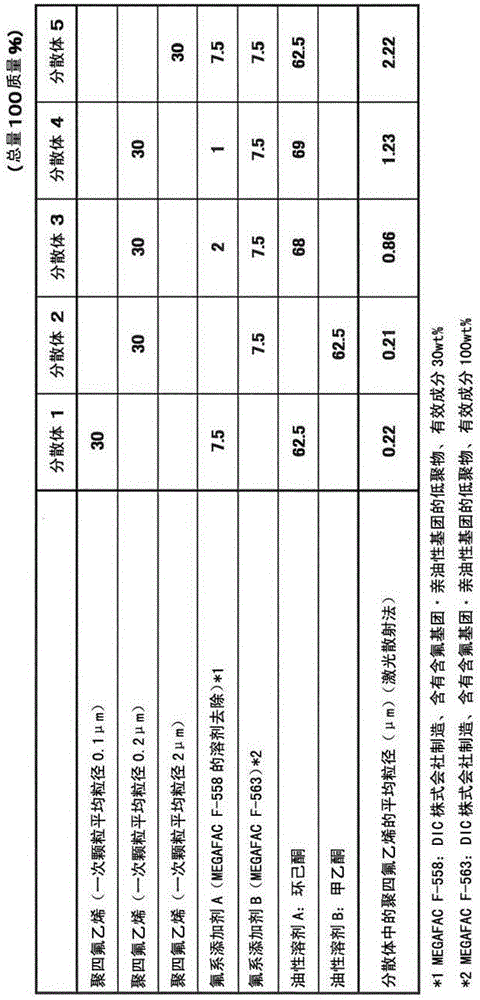

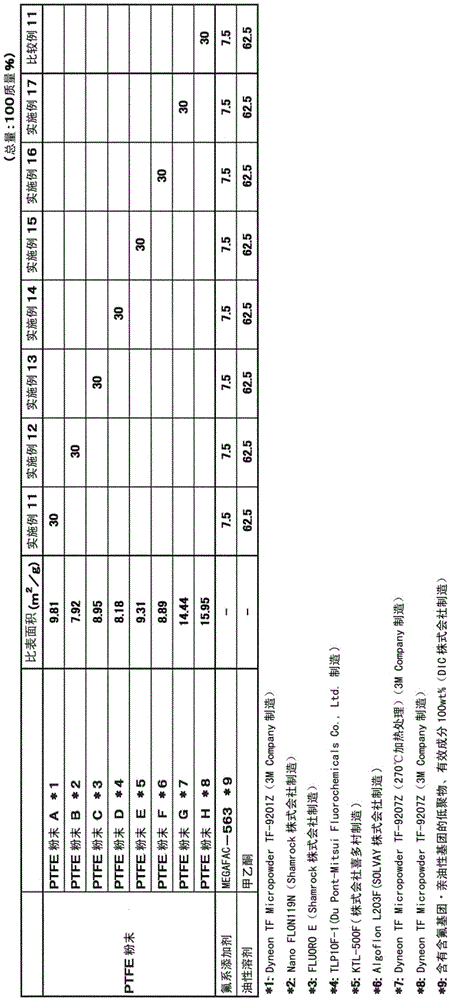

Polytetrafluoroethylene oil-based solvent type dispersion, epoxy resin composition containing polytetrafluoroethylene and cured material thereof

The invention relates to a polytetrafluoroethylene oil-based solvent type dispersion, an epoxy resin composition containing polytetrafluoroethylene and a cured material thereof. In the invention, the polytetrafluoroethylene oil-based solvent type dispersion is used to provide a PTFE oil-based solvent type dispersion having a micro particle size, low viscosity and excellent stability in storage. The polytetrafluoroethylene oil-based solvent type dispersion is characterized by comprising polytetrafluoroethylene having the specific surface area of less than 15m<2> / g and a fluorine type additive being 0.1-50wt% relative to the quality of the polytetrafluoroethylene and at least containing a fluorine-contained group and a lipophilic group. The epoxy resin composition containing the polytetrafluoroethylene oil-based solvent type dispersion having excellent dispersity is used to provide an epoxy resin composition containing the polytetrafluoroethylene and being suitable for an electronic substrate material, an insulation material, a bonding material and the like having a low relative dielectric constant and a low dielectric loss angle tangent, and a cured material thereof.

Owner:MITSUBISHI PENCIL CO LTD

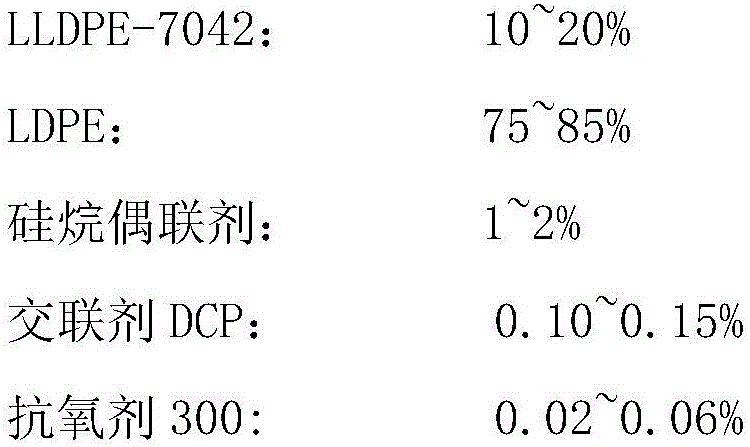

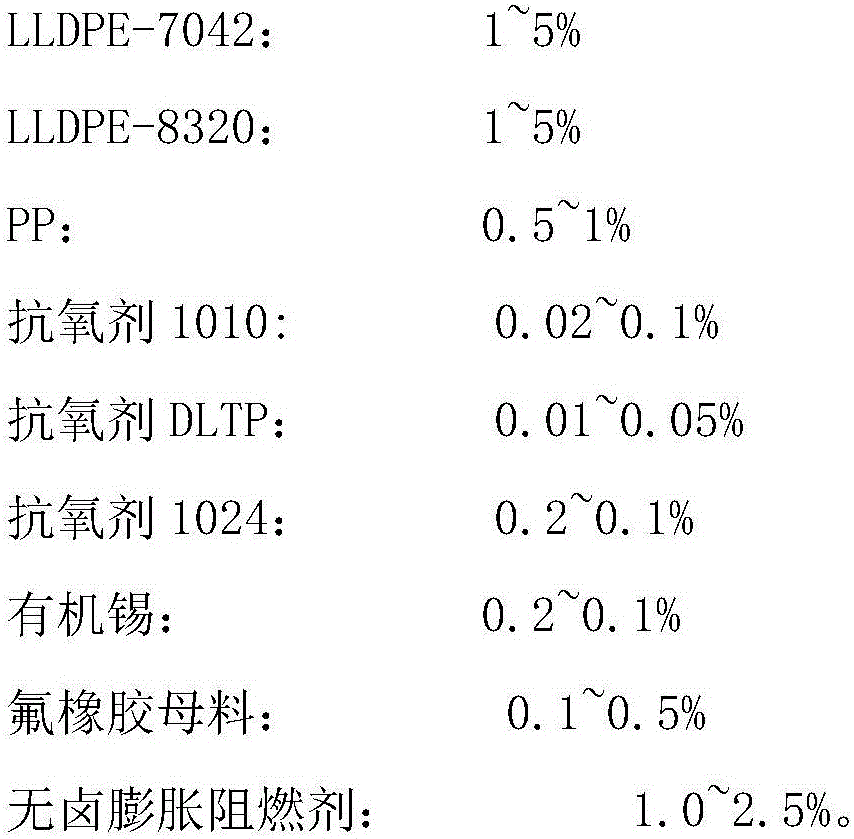

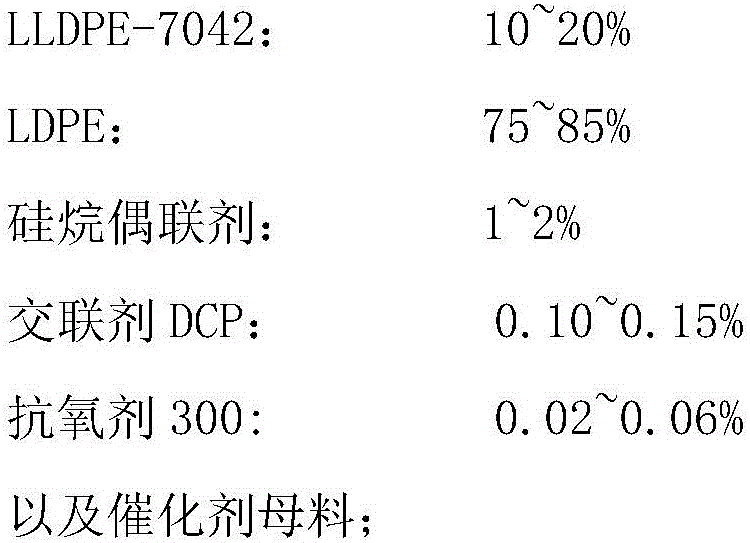

Non-halogen flame-retardant polyethylene sheath insulating material and preparation method thereof

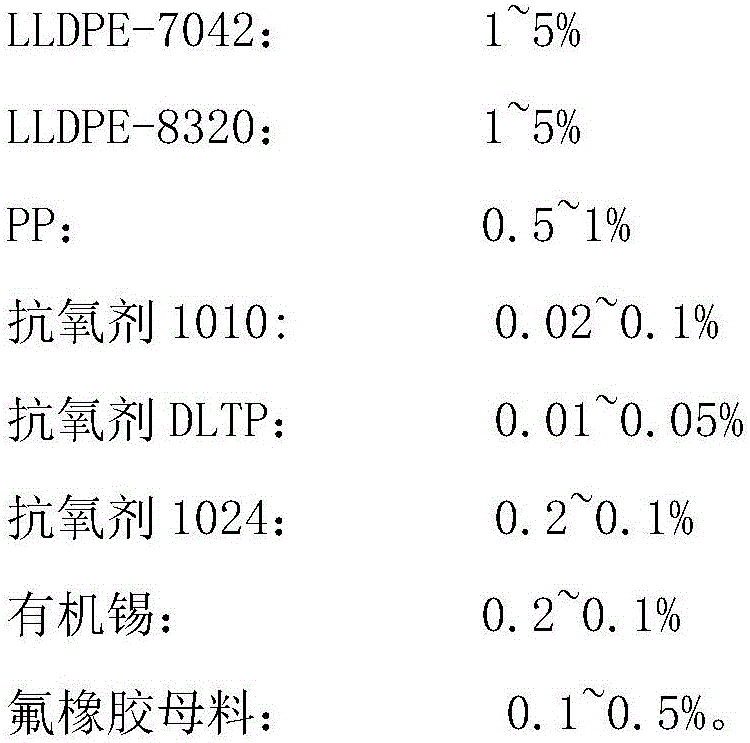

InactiveCN106084409AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolymer science

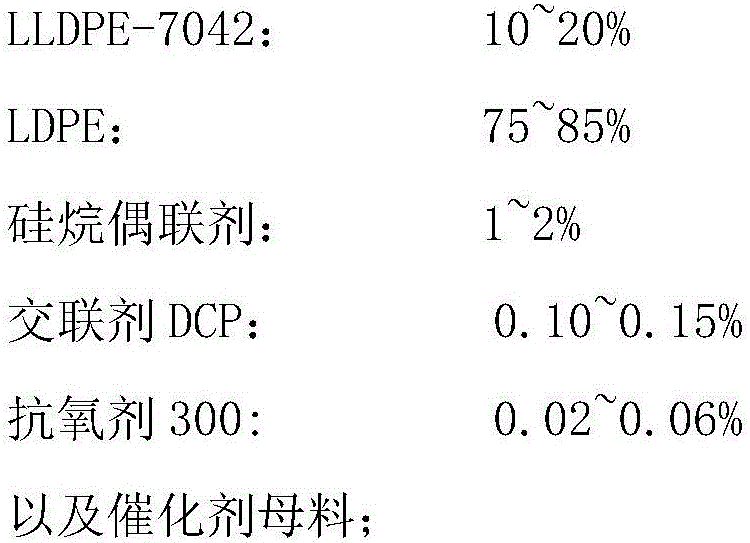

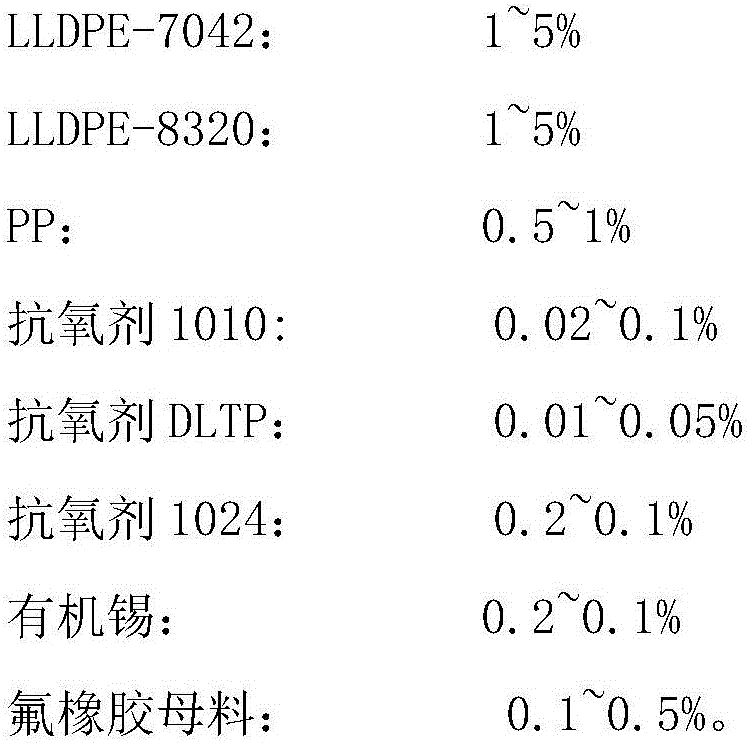

The invention relates to the field of insulating materials, in particular to a non-halogen flame-retardant polyethylene sheath insulating material and a preparation method thereof. The non-halogen flame-retardant polyethylene sheath insulating material is prepared from components as follows: LLDPE-7042 (linear low density polyethylene-7042), LDPE (low-density polyethylene), a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and a catalyst masterbatch, wherein the catalyst masterbatch comprises components as follows: LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluororubber masterbatch and a non-halogen intumescent flame retardant. The material is mainly applied to an insulating layer of a cable and is mainly used for replacing a current PVC (polyvinyl chloride) material, the insulating property of the material is superior to that of PVC, and the silane insulating material is non-toxic and harmless while PVC can release toxic and harmful gas when a wire is on fire caused by aging and the like.

Owner:浙江太湖远大新材料股份有限公司

Method of manufacturing a flexible printed circuit assembly

InactiveUS8015701B2Reduce assembly thicknessSmall dielectric loss tangentPrinted circuit assemblingDielectric materialsFluorocarbonDielectric layer

A flexible printed circuit assembly with a fluorocarbon dielectric layer and an adhesive layer with reduced thickness. The flexible printed circuit assembly includes a first dielectric layer and a signal trace disposed on the first dielectric layer. An adhesive layer with a thickness smaller than a height of the signal trace is disposed on the first dielectric layer, so that only a portion of a side surface of the signal trace is covered. A second dielectric layer made of fluorocarbon is disposed on the adhesive layer, covering a remaining portion of the side surface of the signal trace and a top surface of the signal trace.

Owner:INT BUSINESS MASCH CORP +1

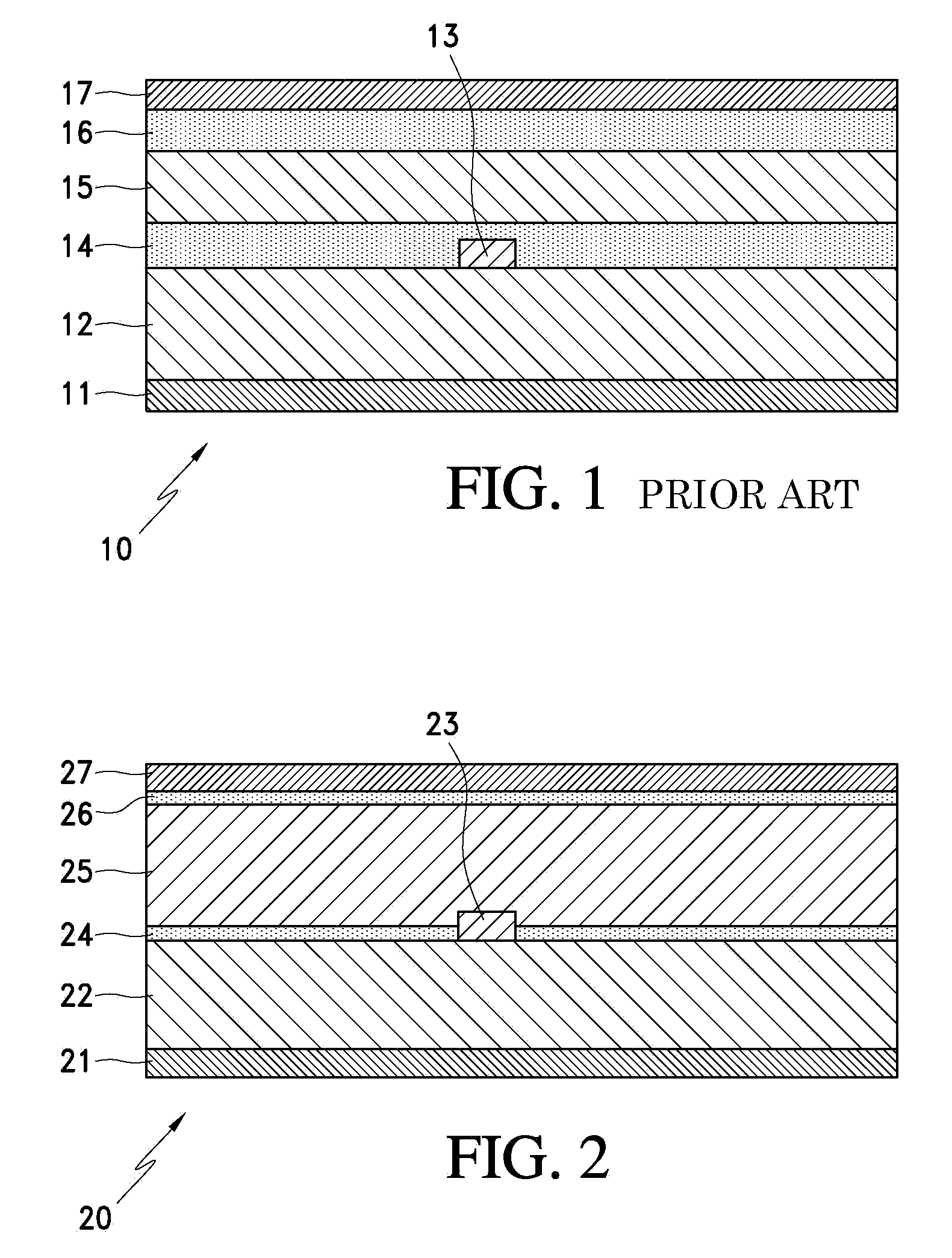

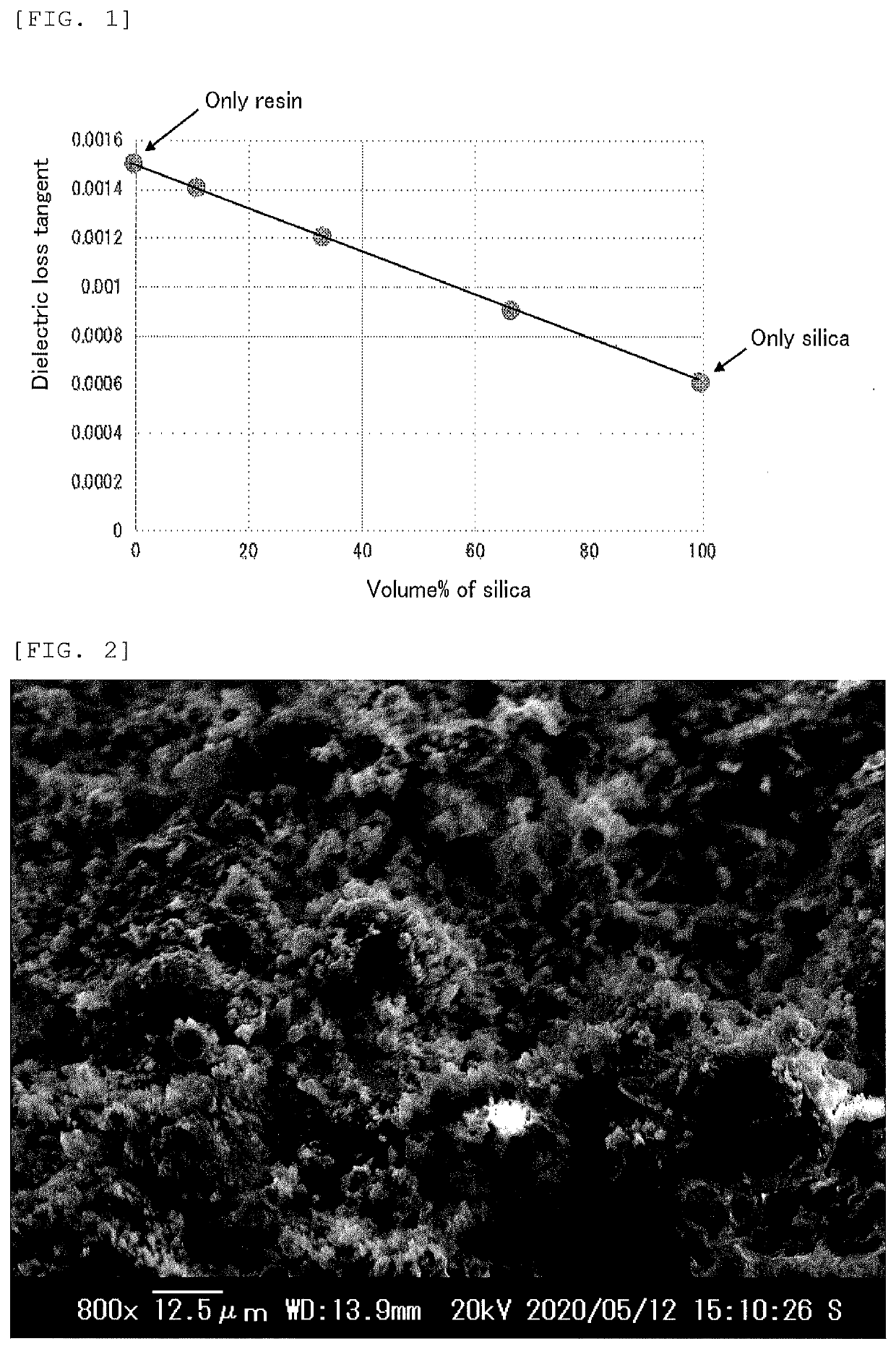

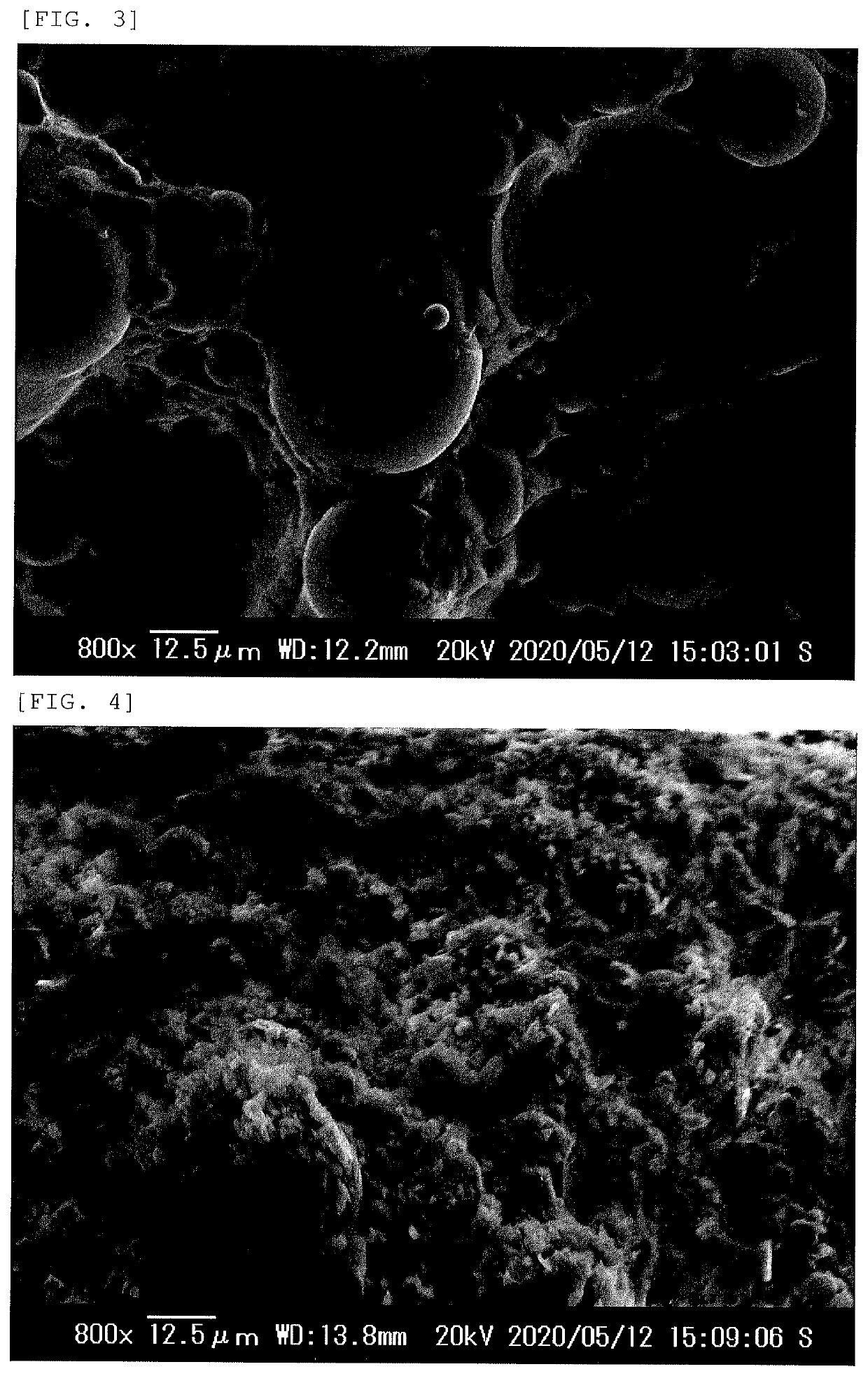

Low dielectric silica powder, resin composition containing the silica powder, and method for manufacturing low dielectric silica powder

PendingUS20210371666A1Small dielectric loss tangentIncrease production capacityPigmenting treatmentSilicaPolymer scienceDielectric loss

The present invention is a low dielectric silica powder, which has an average particle size of 0.1 to 30 μm and a dielectric loss tangent of 0.0005 or less at 10 GHz. An object is to provide: a silica powder with an extremely small dielectric loss tangent; a resin composition containing the same; and a method for manufacturing a silica powder with a low dielectric loss tangent and strong adhesion at the interface to resin.

Owner:SHIN ETSU CHEM IND CO LTD

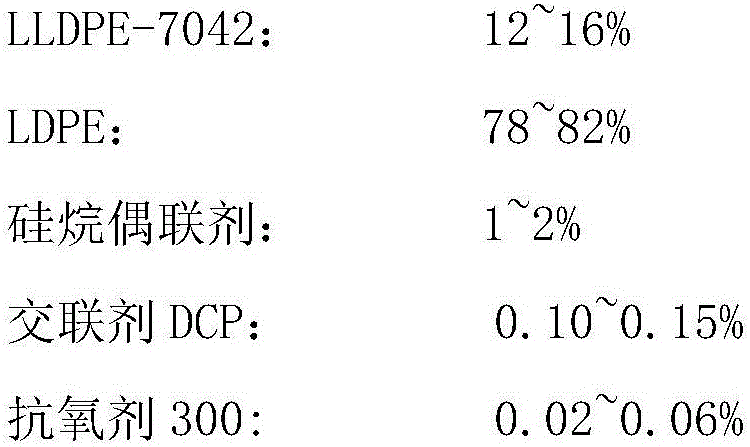

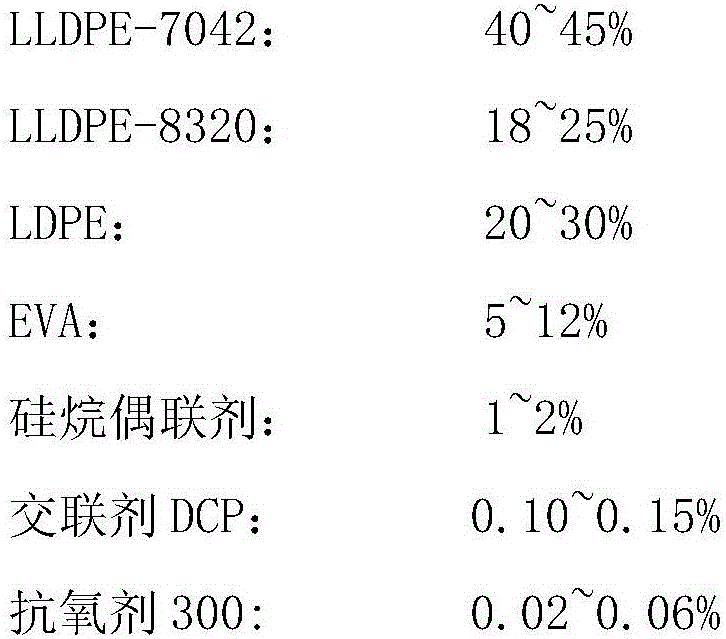

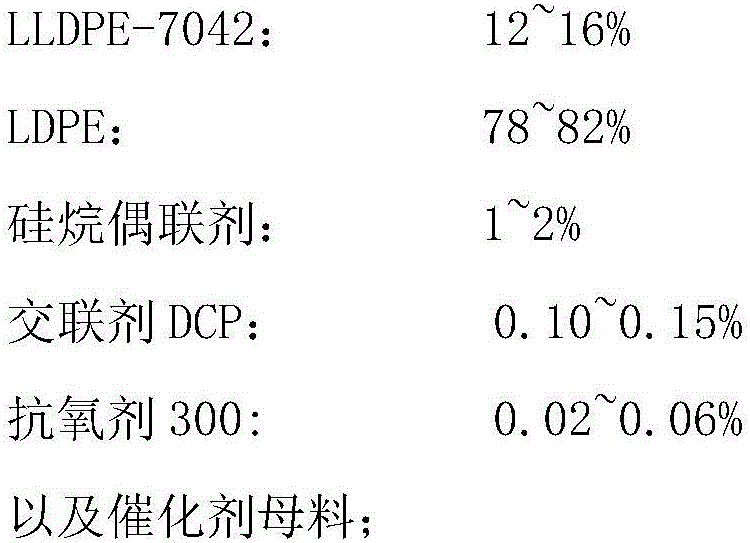

Method for preparing silane crosslinked polyethylene insulation material for electric wires and cables by two-step way

InactiveCN106188742AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsClimate change adaptationLow-density polyethyleneLinear low-density polyethylene

The invention relates to the field of insulation materials, in particular to a silane crosslinked polyethylene insulation material for electric wires and cables. A method for preparing the silane crosslinked polyethylene insulation material for electric wires and cables by a two-step way mainly comprises two steps of 1, preparation of a catalyst master batch; 2, preparation of a finished product. The insulation material is prepared from the following components of LLDPE (linear low density polyethylene)-7042, LDPE (low density polyethylene), a silane coupling agent, a crosslinking agent DCP, an antioxidant 300 and the catalyst master batch; the catalyst master batch comprises the following components of LLDPE-7042, LLDPE-8320, PP (polypropylene), an antioxidant DLTP, an antioxidant 1024, organic tin and a fluororubber master batch. The insulation material has the advantages that the insulation material is mainly used for insulation layers of cables, and is mainly used for replacing the existing PVC (polyvinyl chloride) material; the insulation property is better than the insulation property of PVC, and the poisonous and harmful gas will be released by the PVC when the electric wire is aged and catches a fire, but the silane insulation material has no poison and harm.

Owner:浙江太湖远大新材料股份有限公司

Phase-separation-controlled polybutadiene resin composition and printed wiring board using the resin composition

ActiveUS8097545B2Small dielectric constantImprove the level ofPrinted circuit aspectsSynthetic resin layered productsHeat resistanceHalf-life

It is an objective of this invention to obtain: a composition superior in processability, dielectric properties, heat resistance, and adhesiveness by controlling phase separation of a 1,2-polybutadiene resin composition without deterioration of dielectric properties exhibited in high-frequency regions; and a multilayer printed wiring board using the same.This invention relates to a polybutadiene resin composition, comprising: a crosslinking component (A) comprising repeating units represented by the following formula (1) and having a number average molecular weight of 1000 to 20000; a radical polymerization initiator (B), the one-minute half-life temperature of which is 80° C. to 140° C.; and a radical polymerization initiator (C), the one-minute half-life temperature of which is 170° C. to 230° C.; wherein 3 to 10 parts by weight of the component (B) and 5 to 15 parts by weight of the component (C) are contained relative to 100 parts by weight of the component (A). The invention also relates to a prepreg, a laminate, and a printed wiring board, which are produced using the same.

Owner:HITACHI CHEM CO LTD

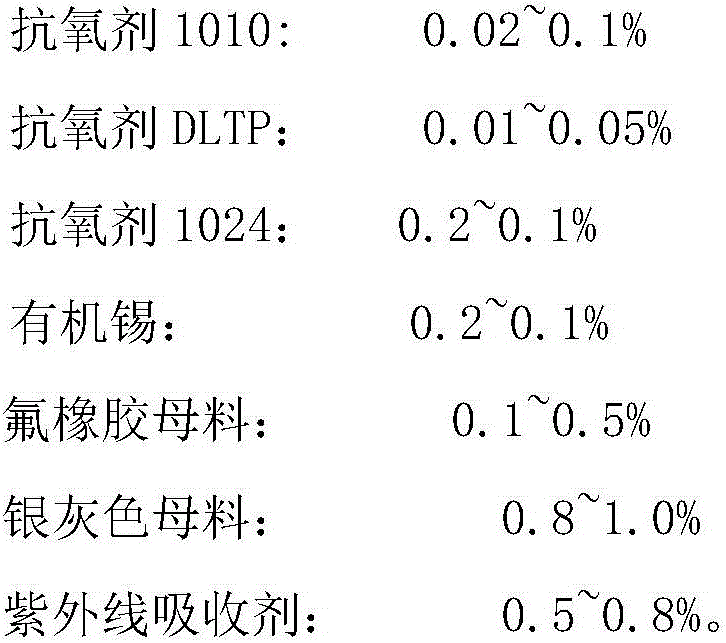

Method for preparing silane crosslinking polyethylene insulating material for 10 kV or below wires and cables through one step

InactiveCN106009234AImprove insulation performanceReduce quality problemsPlastic/resin/waxes insulatorsCross-linkMasterbatch

The invention relates to the field of insulating materials, in particular to a silane crosslinking polyethylene insulating material for 10 kV or below wires and cables. A method for preparing the insulating material for the 10 kV or below wires and cables through one step mainly comprises the two steps of catalyst master batch preparation and finished product preparation. The insulating material is prepared from, by weight, LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organotin and fluororubber master batch. The insulating material is mainly used for insulating layers of the cables and mainly replaces a current PVC material, the insulating property is superior to that of PVC, PVC can emit toxic and harmful gases when the wires fire due to aging and the like, but the silane insulating material is poisonless and harmless.

Owner:浙江太湖远大新材料股份有限公司

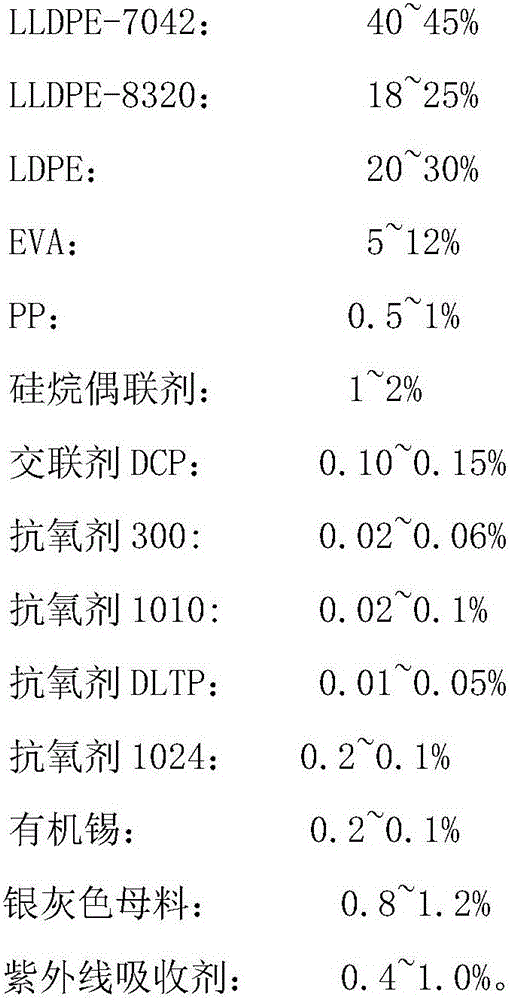

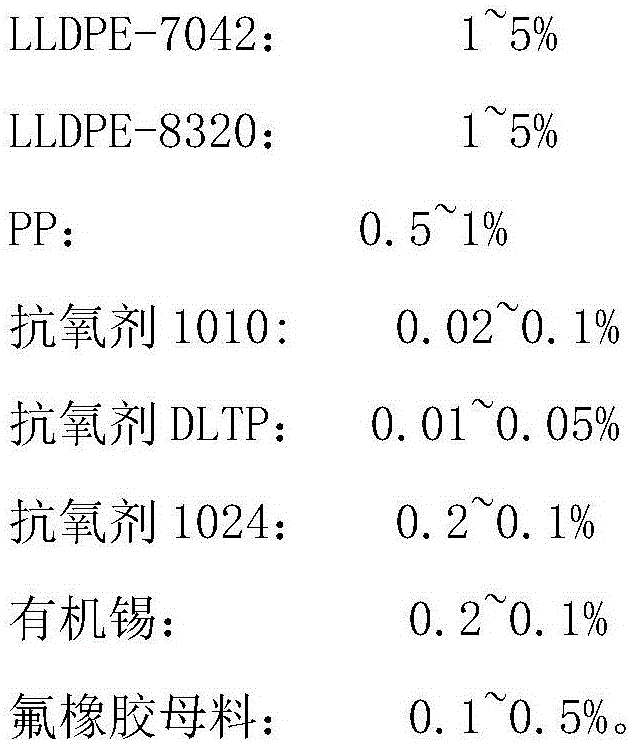

Silane cross-linked polyethylene insulation material for 10 kV and below silver-gray wires and cables, and preparation method thereof

InactiveCN106084440AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsInsulation layerPolymer science

The invention relates to the field of insulation materials, in particular to a silane cross-linked polyethylene insulation material for 10 kV and below silver-gray wires and cables, and a preparation method thereof. The insulation material is prepared by the following components: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a crosslinking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluorine rubber master batch, a UV absorber and a silver-gray master batch. The material is mainly used in an insulation layer of the cable to replace the current main PVC materials, and is better than PVC in insulation property, PVC emits toxic and harmful gases when the wires fire due to aging, while the silane insulation material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Organosilane crosslinked polyethylene wires and cables of 10 kV or below and preparation method thereof

InactiveCN106009226AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to the field of insulating materials, in particular to silane crosslinked polyethylene wires and cables of 10kV and below and a preparation method thereof. The insulating material of the wire and cable is prepared from the following components by weight percentage: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, silane coupling agent, crosslinking agent DCP, antioxidant 300, antioxidant 1010, antioxidant DLTP, antioxidant 1024, organic tin, fluorine rubber masterbatch. The present invention mainly replaces the current PVC material, and its insulation performance is better than that of PVC. However, PVC will release toxic and harmful gases when the wires are aging and catch fire, while the silane insulating material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

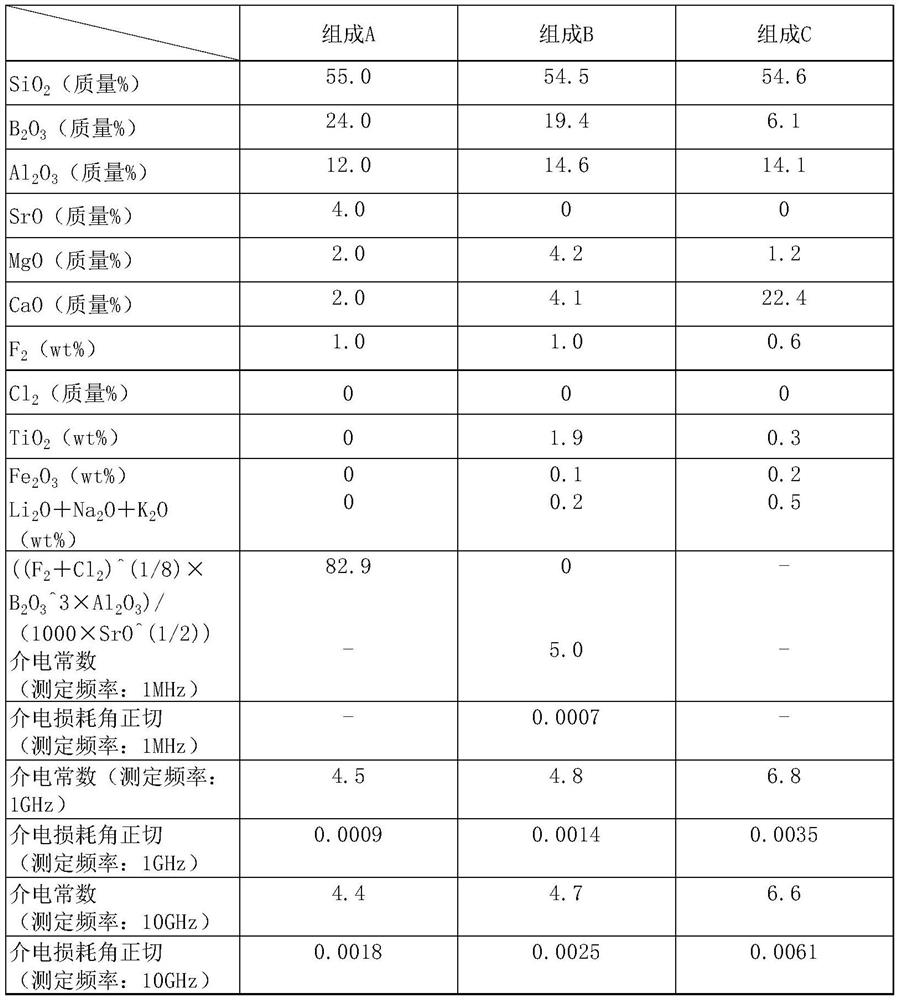

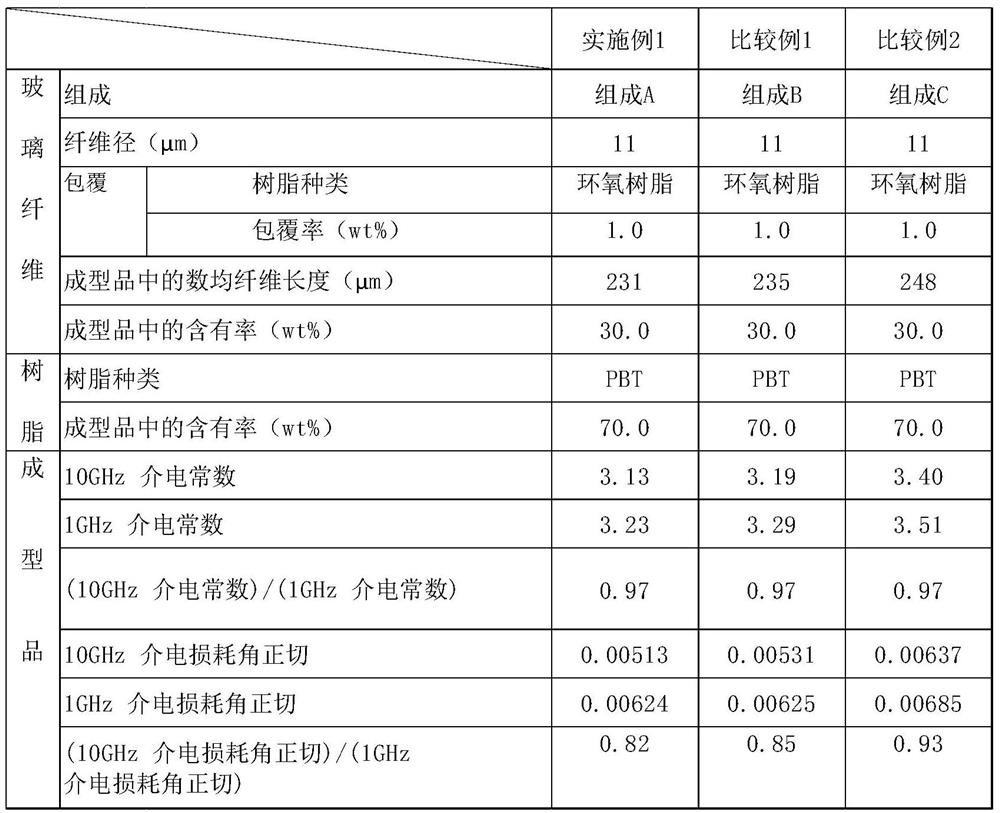

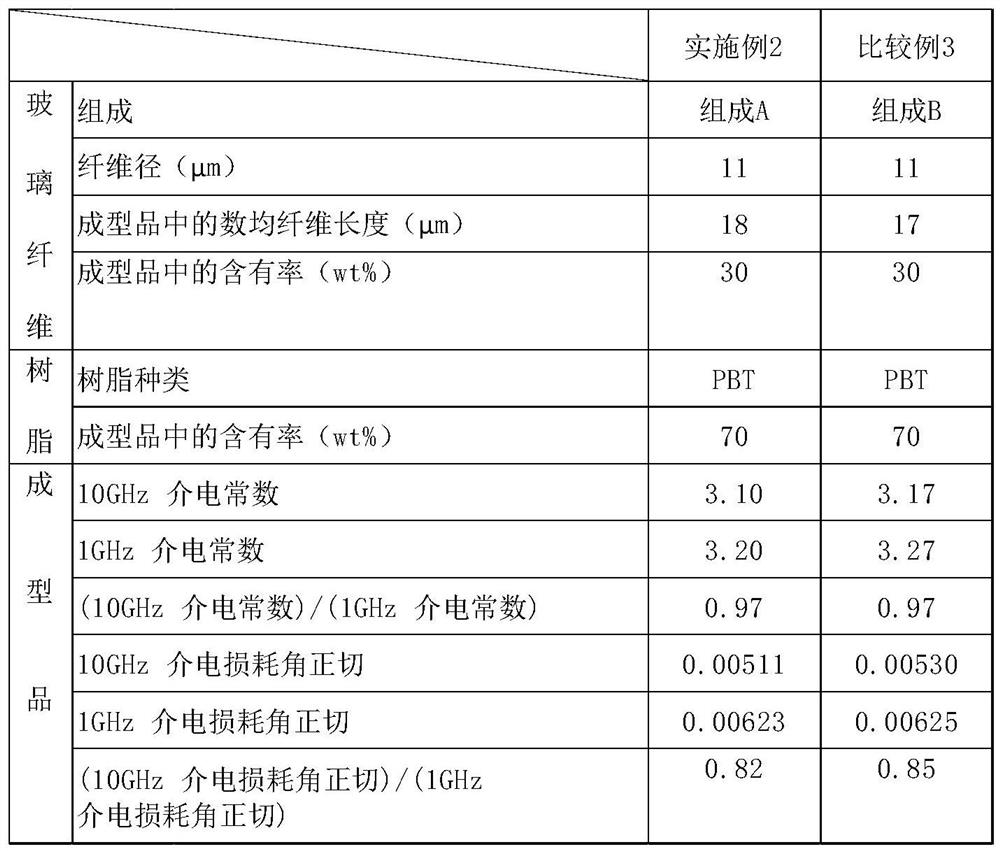

Glass fiber-reinforced resin molded article

Provided is a glass fiber-reinforced resin molded article having a low dielectric constant and a low dielectric loss tangent, especially a low dielectric loss tangent, in the high-frequency region of 10 GHz and above. The glass fiber-reinforced resin molded article contains glass fibers in a range of 10-90 mass% and resin in a range of 90-10 mass% relative to the total weight of the glass fiber-reinforced resin molded article. The glass fibers have a composition that includes SiO2 in a range of 52.0-59.5 mass%, B2O3 in a range of 17.5-25.5 mass%, Al2O3 in a range of 9.0-14.0 mass%, SrO in a range of 0.5-6.0 mass%, MgO in a range of 1.0-5.0 mass%, CaO in a range of 1.0-5.0 mass%, and a total of F2 and Cl2 in a range of 0.1-2.5 mass% relative to the total weight of the glass fibers. The glass fibers have a number average fiber length of 1-10,000 [mu]m.

Owner:NITTO BOSEIKI CO LTD

Flame-retardant silane crosslinked polyethylene insulating material and preparation method thereof

PendingCN113563657AGood heat denaturation resistanceStrong overload resistancePlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

The invention discloses a flame-retardant silane crosslinked polyethylene insulating material and a preparation method thereof. The flame-retardant silane crosslinked polyethylene insulating material is prepared from the following components in percentage by weight: 4%-6% of a halogen flame retardant, 4%-7% of ethylene-vinyl acetate, 8%-15% of LLDOE-7042, 75%-85% of LDEP resin, 1%-2% of a silane coupling agent, 0.1-0.3% of an initiator, 0.2-0.4% of an antioxidant, 0.1-0.5% of fluororubber master batch, 0.2-0.5% of organic tin, 0.4-1% of an anti-ultraviolet light absorber and 2-3% of a catalyst. The material provided by the invention has the advantages of good thermal denaturation resistance, strong overload resistance, improved mechanical properties at high temperature, enhanced chemical stability and solvent resistance, reduced cold flow property, and high insulation resistance.

Owner:浙江太湖远大新材料股份有限公司

Resin composition, thermosetting film using same, resin cured product, laminated board, printed circuit board and semiconductor device

ActiveCN109923176BHigh bonding strengthLow dielectric constantCircuit susbtrate materialsMetal layered productsEpoxyMetallic foil

The present invention provides a substrate having excellent adhesive strength to substrate materials such as metal foil and polyimide contained in the wiring of a printed circuit board, and has dielectric properties in a high-frequency region, specifically, a frequency of 1 to 100 GHz. A thermosetting film exhibiting a low dielectric constant (ε) and a low dielectric loss tangent (tanδ) in the region, and a resin composition used for producing the thermosetting film. The resin combination includes (A) an epoxy resin, (B) a resin having a dielectric loss tangent (tanδ) of less than 0.005 in the frequency range of 1 to 100 GHz, and (C) a carbon atom number in the 1-position of a heterocyclic ring. An imidazole compound having a side chain of an alkyl group having 5 or more.

Owner:NAMICS CORPORATION

Silane crosslinking polyethylene insulating material electric wire cable and preparation method thereof

InactiveCN106046501AReduce quality problemsGood heat denaturation resistancePlastic/resin/waxes insulatorsCross-linkMasterbatch

The invention relates to the field of insulating material electric wire cables, in particular to a silane crosslinking polyethylene insulating material electric wire cable and a preparation method thereof. The electric wire cable comprises an insulating material and a wire; the insulating material is prepared from LLDPE-7042, LDPE, a silane coupling agent, a cross-linking agent DCP, an antioxidant 300 and catalyst masterbatch; the catalyst masterbatch is prepared from LLDPE-7042, LLDPE-8320, PP, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin and fluororubber masterbatch. According to the silane crosslinking polyethylene insulating material electric wire cable and the preparation method thereof, the insulating material mainly replaces an existing PVC material, the insulating property is superior to that of the PVC, the PVC can release poisonous and harmful gas when a fire breaks out due to the fact that an electric wire is aged, but the silane insulating material is nontoxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Silane cross-linked polyethylene insulation material for 10 kV and below black wires and cables, and preparation method thereof

InactiveCN106084439AImprove insulation performanceStable speedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to the field of insulation materials, in particular to a silane cross-linked polyethylene insulation material for 10 kV and below black wires and cables, and a preparation method thereof. The insulation material is prepared by the following components in percentage by weight: LLDPE-7042, LLDPE-8320, LDPE, EVA, PP, a silane coupling agent, a crosslinking agent DCP, an antioxidant 300, an antioxidant 1010, an antioxidant DLTP, an antioxidant 1024, organic tin, a fluorine rubber masterbatch and a black masterbatch. The material is mainly used in an insulation layer of the cable to replace the current main PVC materials, and is better than PVC in insulation property, PVC emits toxic and harmful gases when the wires fire due to aging, and the silane insulation material is non-toxic and harmless.

Owner:浙江太湖远大新材料股份有限公司

Resin composition

A resin composition including a thermoplastic resin and / or a thermosetting resin, and a glass component dispersed in the thermoplastic resin and / or the thermosetting resin, when a residue after ashing of the resin composition is subjected to an ICP analysis, a calcium content in the resin composition is 0% to 27% by mass with respect to 100% by mass of a metal content in the resin composition and a calcium content in the glass component is 0% to 27% by mass with respect to 100% by mass of the metal content in the glass component.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com