Active ester resin and cured product thereof

A technology of active ester and resin, which is applied in the field of curable resin composition and active ester resin, can solve the problems of low dielectric constant, dielectric loss tangent, and unsatisfactory market requirements, and achieve low curing shrinkage and dielectric loss The effect of low tangent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

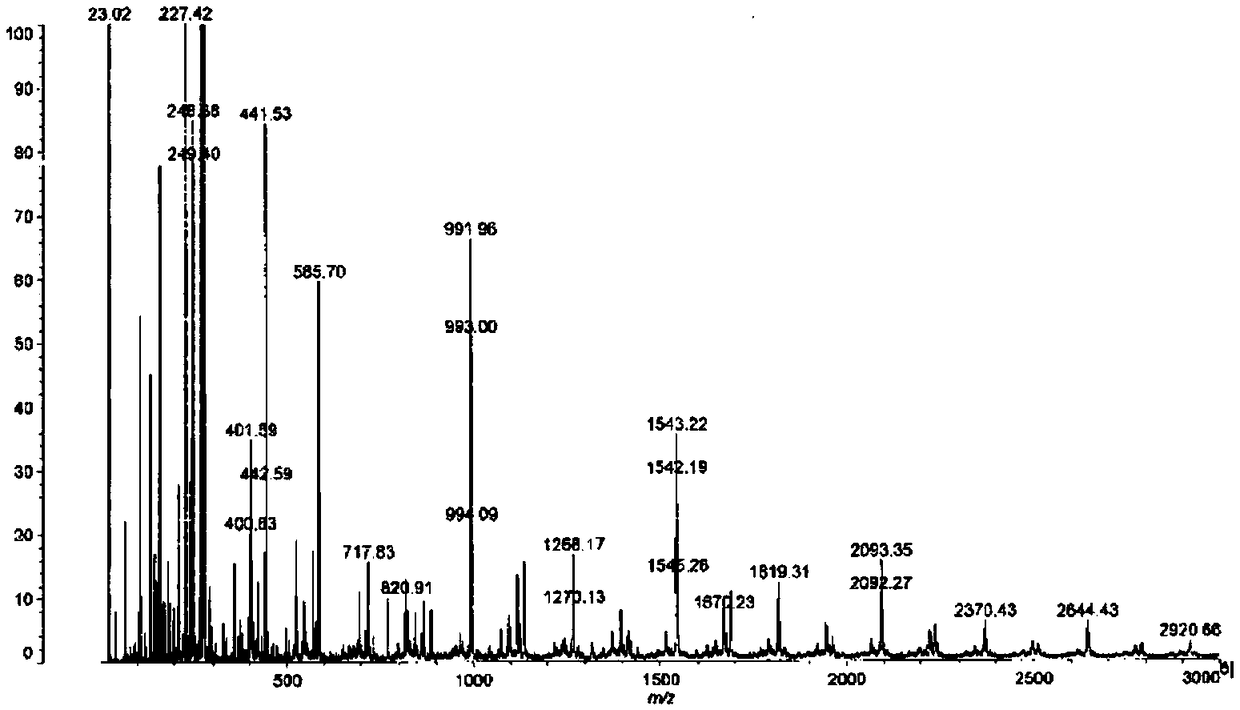

Embodiment 1

[0156] The manufacture of embodiment 1 active ester resin (1)

[0157] In a flask equipped with a thermometer, a dropping funnel, a condenser, a fractionating tube, and an agitator, 433 parts by mass of 1-naphthol, 108 parts by mass of toluene, 99 parts by mass of dicyclopentadiene, and p-toluenesulfonic acid monohydrate 27 parts by mass. It heated up to 130 degreeC, stirring the content of the flask, and stirred at 130 degreeC for 2 hours, and made it react. After completion of the reaction, 12 parts by mass of a 49% sodium hydroxide aqueous solution was added for neutralization, 200 parts by mass of toluene was added, and 100 parts by mass of water was washed three times. Toluene and the like were distilled off under heating and reduced pressure to obtain 522 parts by mass of a mixture (1) containing unreacted 1-naphthol and polynaphthol resin (B-1). The hydroxyl equivalent weight of the obtained mixture (1) was 234 g / equivalent.

[0158] 141 parts by mass of isophthaloyl...

Embodiment 2

[0159] The manufacture of embodiment 2 active ester resin (2)

[0160] In a flask equipped with a thermometer, a dropping funnel, a condenser, a fractionating tube, and an agitator, 404 parts by mass of 1-naphthol, 500 parts by mass of toluene, 96 parts by mass of p-xylylenedimethanol, and p-toluenesulfonic acid monohydrate 6 parts by mass. It heated up to 120 degreeC, stirring the content of the flask, and stirred at 120 degreeC for 1 hour, and made it react. After completion of the reaction, 4 parts by mass of a 49% sodium hydroxide aqueous solution was added for neutralization, and then 400 parts by mass of toluene was added, followed by washing with 200 parts by mass of water three times. Toluene and the like were distilled off under heating and reduced pressure to obtain 448 parts by mass of a mixture (2) containing unreacted 1-naphthol and polynaphthol resin (B-2). The hydroxyl equivalent weight of the obtained mixture (2) was 170 g / equivalent.

[0161] 141 parts by m...

Embodiment 3

[0162] The manufacture of embodiment 3 active ester resins (3)

[0163] In a flask equipped with a thermometer, a dropping funnel, a condenser, a fractionating tube, and an agitator, 404 parts by mass of 1-naphthol, 560 parts by mass of toluene, 150 parts by mass of dimethylolbiphenyl, and one p-toluenesulfonic acid Hydrate 6 mass parts. It heated up to 120 degreeC, stirring the content of the flask, and stirred at 120 degreeC for 1 hour, and made it react. After completion of the reaction, 4 parts by mass of a 49% sodium hydroxide aqueous solution was added for neutralization, and then 400 parts by mass of toluene was added, followed by washing with 200 parts by mass of water three times. Toluene and the like were distilled off under heating and reduced pressure to obtain 510 parts by mass of a mixture (3) containing unreacted 1-naphthol and polynaphthol resin (B-3). The hydroxyl equivalent weight of the obtained mixture (3) was 189 g / equivalent.

[0164] 141 parts by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com