Insulating material with high heat resistance and preparation method thereof as well as prepared cable protection pipe

A technology of cable protection tube and insulating material, which is applied in the field of high heat-resistant insulating material and its preparation method and the obtained cable protection tube, and can solve the problems affecting the accuracy, heat resistance, carrying capacity and heat dissipation of medical equipment affecting aviation flight safety. Low stability, interference with normal functions of electronic devices, etc., to achieve the effect of convenient control, excellent electrical insulation performance, and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

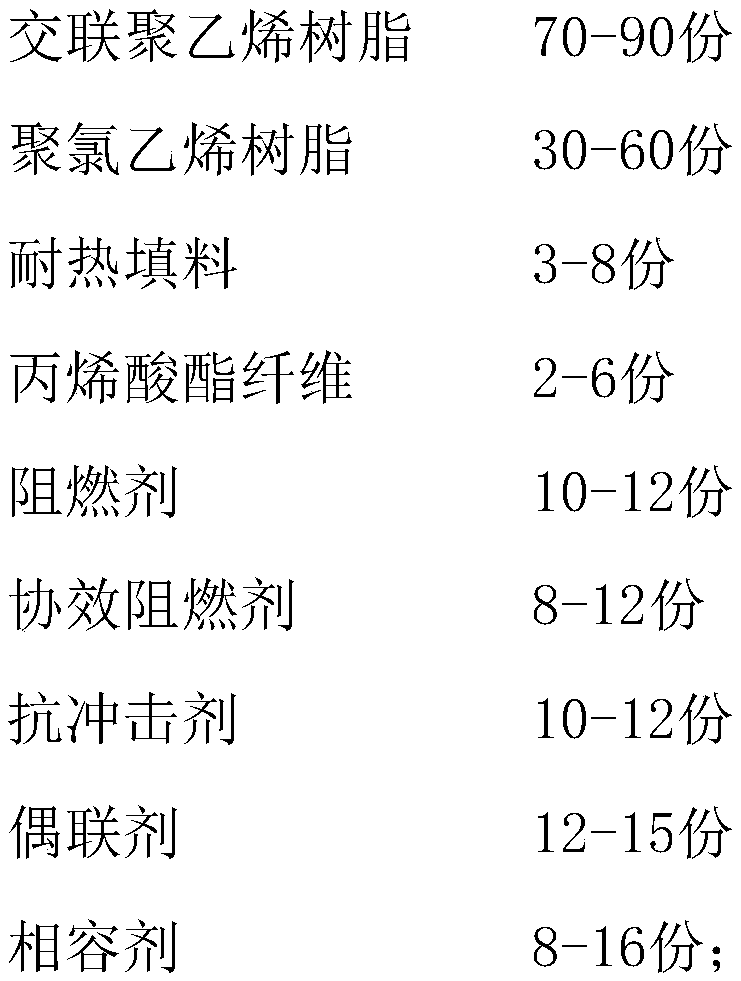

[0044] A high heat-resistant insulating material, comprising the following raw materials in parts by weight:

[0045]

[0046] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 3:6:1.5.

[0047] The flame retardant is decabromodiphenylethane; the synergistic flame retardant is magnesium silicate.

[0048] The anti-impact agent is acrylonitrile-butadiene-styrene copolymer; the coupling agent is pyrophosphate titanate; styrene-acrylonitrile copolymer is grafted with glycidyl methacrylate.

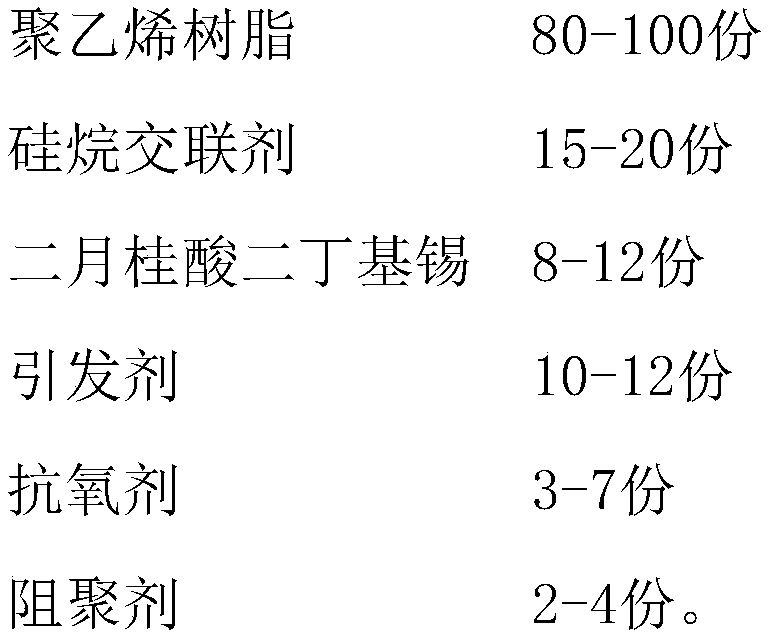

[0049] Described cross-linked polyethylene resin comprises the raw material of following weight portion:

[0050]

[0051] The silane crosslinking agent is γ-aminopropyltriethoxysilane; the initiator is dicumyl hydroperoxide; the antioxidant is three [2.4-di-tert-butylphenyl] phosphorous acid Esters; the polymerization inhibitor is 2-tert-butyl hydroquinone.

[0052] A method for preparing a high heat-resistant ins...

Embodiment 2

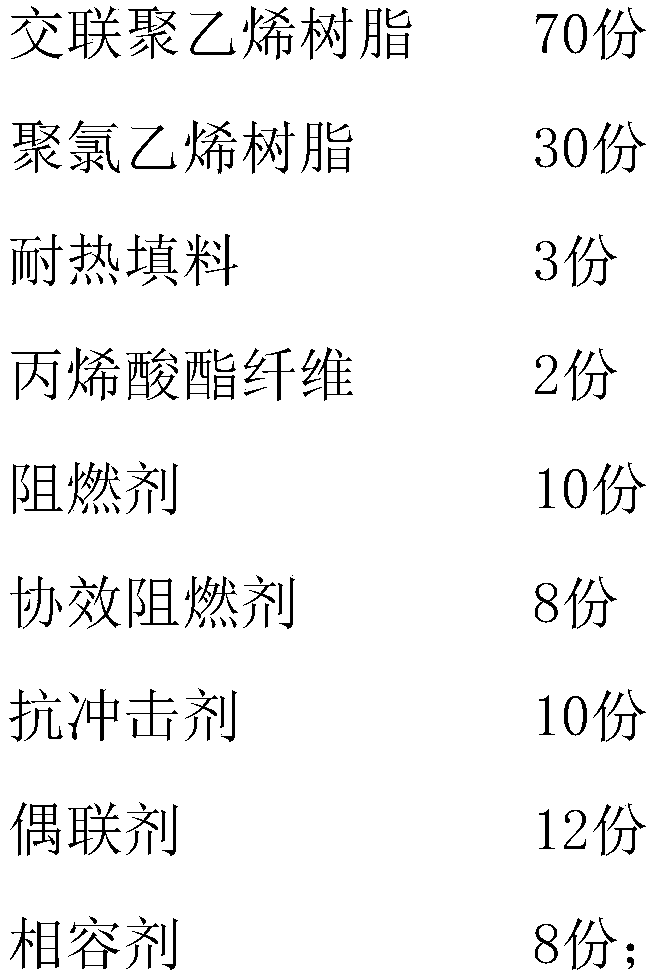

[0057] A high heat-resistant insulating material, comprising the following raw materials in parts by weight:

[0058]

[0059] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 4:5:1.6.

[0060] The flame retardant is tetrabromobisphenol A or 1,2-bis(tetrabromophthalimide)ethane; the synergistic flame retardant is zinc oxide.

[0061] The anti-impact agent is styrene-butadiene-styrene copolymer; the coupling agent is vinyl tris (β-methoxyethoxy) silane; hydrogenated styrene-butadiene-styrene copolymer grafted with glycidyl methacrylate.

[0062] Described cross-linked polyethylene resin comprises the raw material of following weight portion:

[0063]

[0064] The silane crosslinking agent is 3-glycidyl etheroxypropyl trimethoxysilane; the initiator is dicumyl peroxide; the antioxidant is tetrakis[β-(3,5-ditertiary Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; The polymerization inhibitor...

Embodiment 3

[0070] A high heat-resistant insulating material, comprising the following raw materials in parts by weight:

[0071]

[0072]

[0073] The heat-resistant filler is a mixture of calcium carbonate, lignocellulose and magnesium silicide in a weight ratio of 5:4:1.8.

[0074] The flame retardant is decabromodiphenyl ether or 2,4,6-tribromophenyl allyl ether; the synergistic flame retardant is antimony trioxide.

[0075] The anti-impact agent is methyl methacrylate-butadiene-styrene copolymer; the coupling agent is vinyltriethoxysilane or methyltriethoxysilane; ethylene-acrylic acid-methyl ester Glycidyl methacrylate.

[0076] Described cross-linked polyethylene resin comprises the raw material of following weight portion:

[0077]

[0078] The silane crosslinking agent is vinyltrimethoxysilane; the initiator is dicumyl peroxide; the antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] pentaerythritol ester; the polymerization inhibitor i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com