Flame-retardant silane crosslinked polyethylene insulating material and preparation method thereof

A technology of cross-linked polyethylene and insulating materials, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problem that the cable material or structure cannot meet the needs of the industry, and the high temperature resistance and flame retardancy of the cable cannot meet the requirements , Corrosion of the cable structure, etc., to achieve the effects of improving environmental stress crack resistance and heat aging resistance, good thermal denaturation resistance, and reducing cold flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

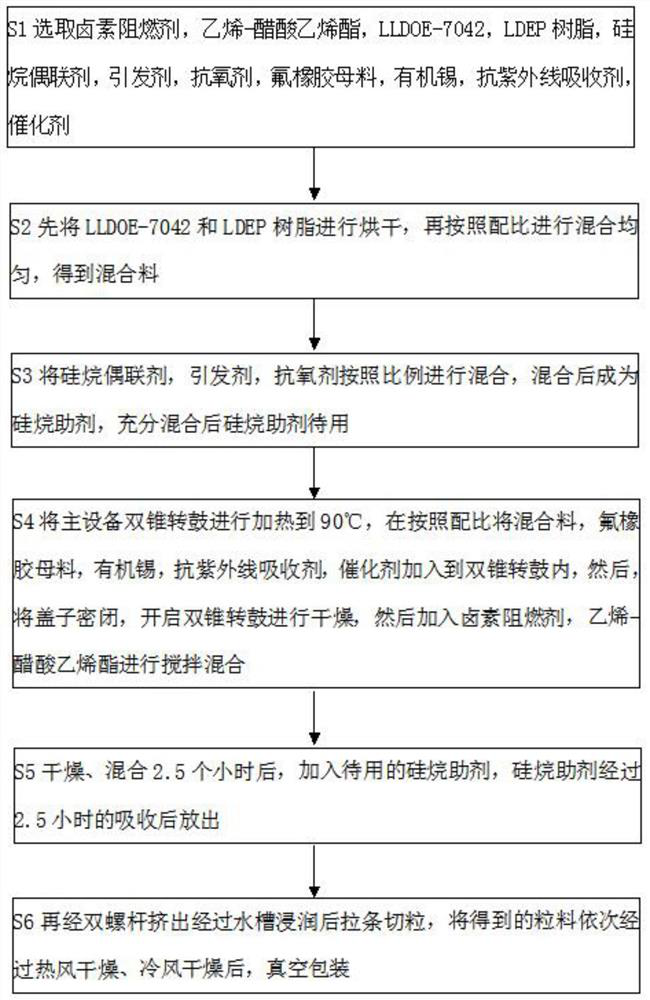

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0022] refer to figure 1 , a flame-retardant silane cross-linked polyethylene insulating material, the insulating material is prepared from the following components by weight percentage: halogen flame retardant: 4-6%, ethylene-vinyl acetate: 4-7%, LLDOE- 7042: 8-15%, LDEP resin: 75-85%, silane coupling agent: 1-2%, initiator: 0.1-0.3%, antioxidant: 0.2-0.4%, fluororubber masterbatch: 0.1-0.5 %, organotin: 0.2-0.5%, anti-ultraviolet absorber 0.4-1%, catalyst 2-3%.

[0023] In the present invention, the insulating material is specifically: halogen flame retardant: 5%, ethylene-vinyl acetate: 5%, LLDOE-7042: 9%, LDEP resin: 75%, silane coupling agent: 1.5%, Initiator:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com