Resin composition, thermosetting film using same, resin cured product, laminate, printed wiring board and semiconductor device

A technology of resin composition and resin cured product, which is applied in the direction of printed circuit, printed circuit parts, circuit substrate materials, etc., and can solve the problems of insufficient bonding strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

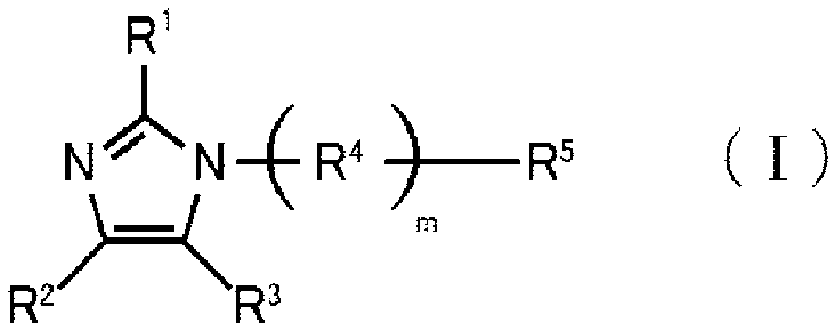

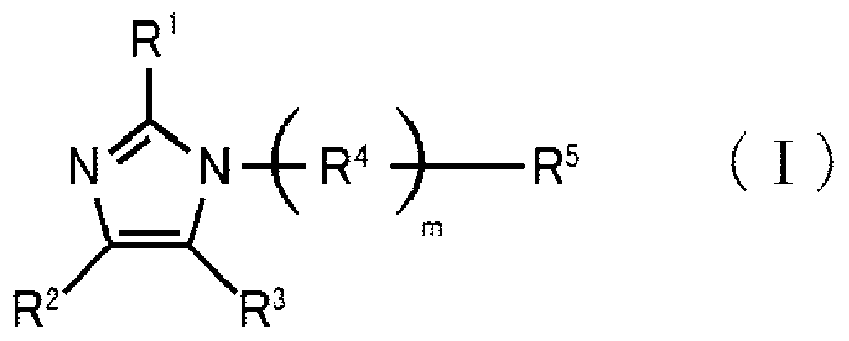

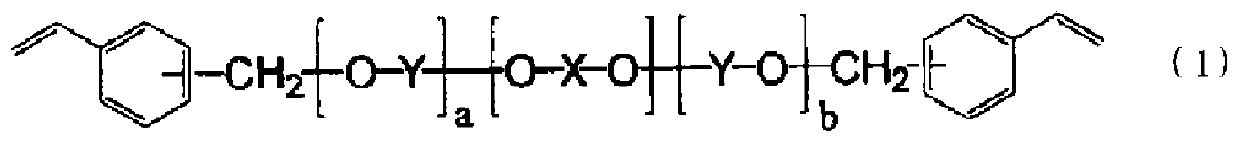

Method used

Image

Examples

Embodiment 1~11

[0107] (Examples 1-11, Comparative Examples 1-4)

[0108] According to the formula shown in the following table, measure the specified amount of each resin (A-1, A-2, A-3, B-1, B-2, B-3, B-4 and B- 5) and a specified amount of toluene. Next, after heating and dissolving the mixture of the resin and toluene using a heating stirrer, it was cooled to room temperature. Next, predetermined amounts of imidazole compounds and the like (C-1, C'-1, C'-2, C'-3, and C'-4) are thrown into the mixture. Then, the obtained mixture of (A) component, (B) component, and (C) or (C') component was stirred and mixed with a self-rotating or revolving mixer (MAZERUSTAR (trade name), manufactured by Kurabo Bosho Co., Ltd.) 3 minutes, thereby preparing a resin composition. However, in Example 11, fused spherical silica filler (manufactured by Ronsen Co., Ltd. MP-15EF, average particle diameter: 1.5 μm) was also added to the resin composition as an inorganic filler, and then, using a bead mill, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com