Organosilane crosslinked polyethylene wires and cables of 10 kV or below and preparation method thereof

A silane cross-linking, wire and cable technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of large gaps, achieve high insulation resistance, improve mechanical properties, and good thermal denaturation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

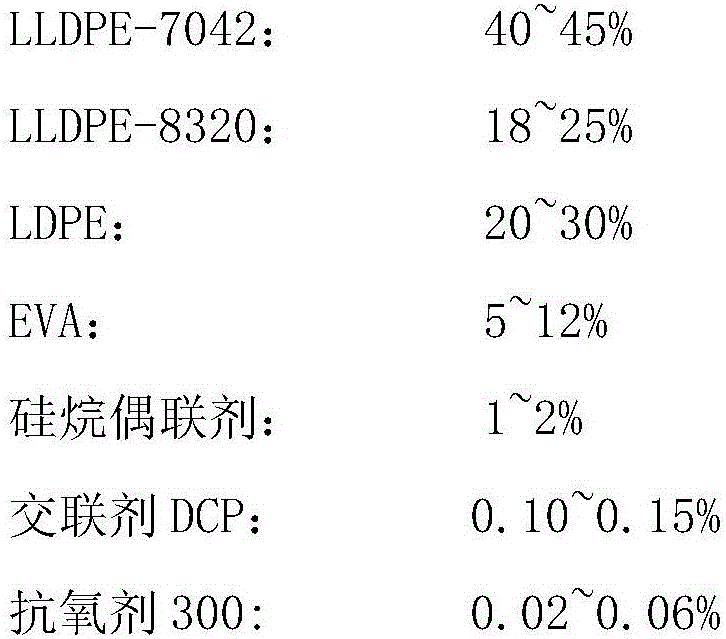

[0045] 10kV and below silane cross-linked polyethylene wire and cable, the wire and cable include insulating material and wires arranged in the insulating material, the insulating material is prepared from the following components by weight percentage:

[0046]

[0047]

[0048] Two-step method for preparing 10kV and below silane cross-linked polyethylene wire and cable. The preparation of insulating materials is mainly composed of two parts, one is the preparation of the catalyst masterbatch, and the other is the preparation of the finished product.

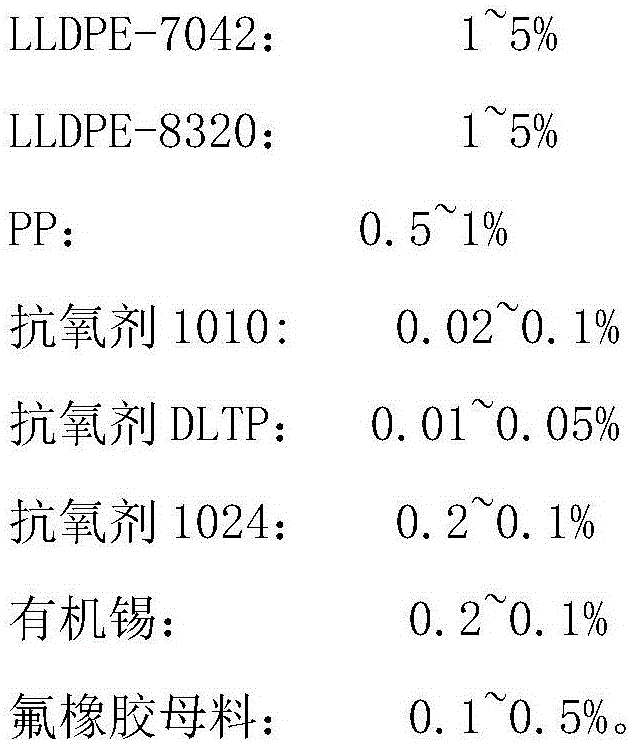

[0049] 1. Preparation of catalyst masterbatch: The catalyst masterbatch accounts for 5% of the total material composition, and the specific formula is as follows:

[0050]

[0051] Stir the above materials (total 50 kg) in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then pour them into the hopper of the extruder (extruder temperature: 140~180°C), after twin-screw extrusion After...

Embodiment 2

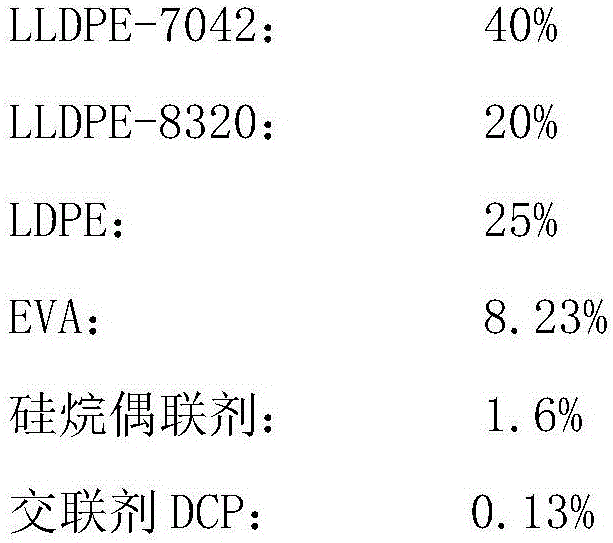

[0061] 10kV and below silane cross-linked polyethylene wire and cable, the wire and cable include insulating material and wires arranged in the insulating material, the insulating material is prepared from the following components by weight percentage:

[0062]

[0063] The insulating material mentioned above was prepared by the two-step method of Example 1.

Embodiment 3

[0065] 10kV and below silane cross-linked polyethylene wire and cable, the wire and cable include insulating material and wires arranged in the insulating material, the insulating material is prepared from the following components by weight percentage:

[0066]

[0067]

[0068] A method for preparing silane cross-linked polyethylene wires and cables of 10kV and below in one step. The preparation of insulating materials is mainly composed of two parts, one is the preparation of catalyst masterbatch, and the other is the preparation of finished products.

[0069] 1. Preparation of catalyst masterbatch: The catalyst masterbatch accounts for 5% of the total material composition, and the specific formula is as follows:

[0070]

[0071] Stir the above materials (total 50 kg) in the mixer, first stir at low speed for 1 minute and then at high speed for 3 minutes, then pour them into the hopper of the extruder (extruder temperature: 140~180°C), after twin-screw extrusion A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com