Glass fiber-reinforced resin molded article

A glass fiber and resin molding technology, applied in the field of glass fiber reinforced resin molded products, can solve the problem of heat generation of resin molded products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

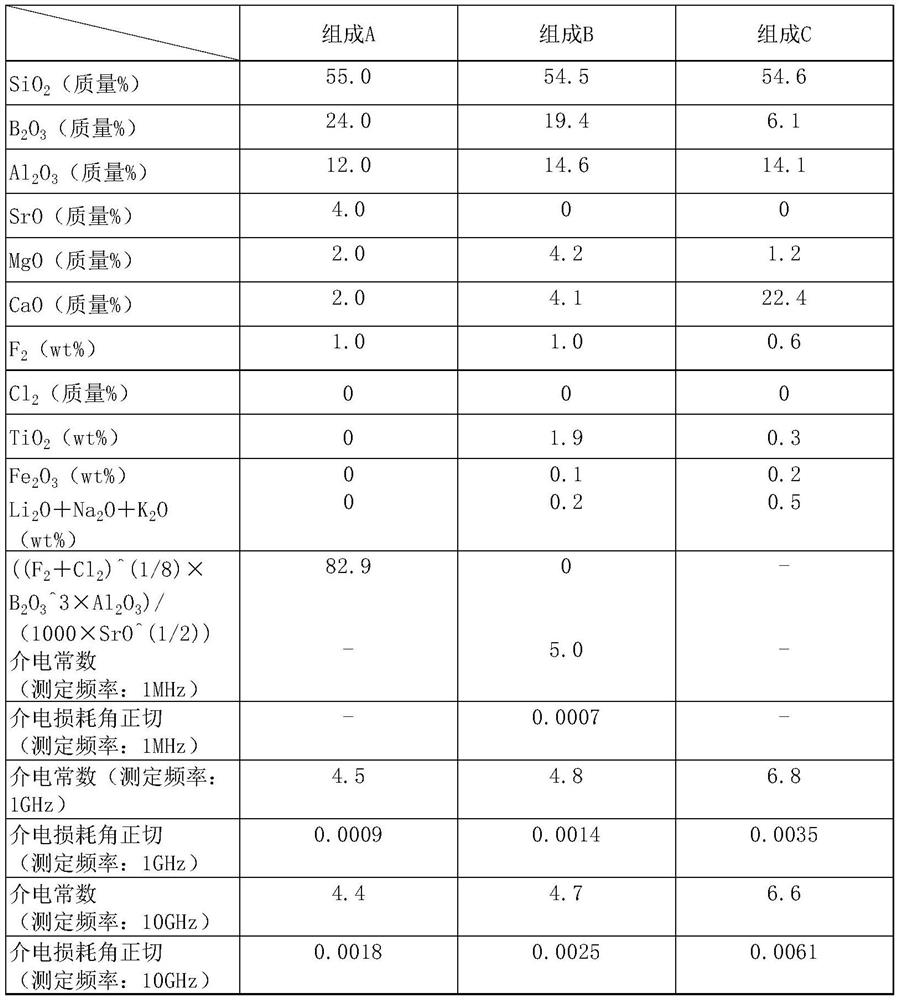

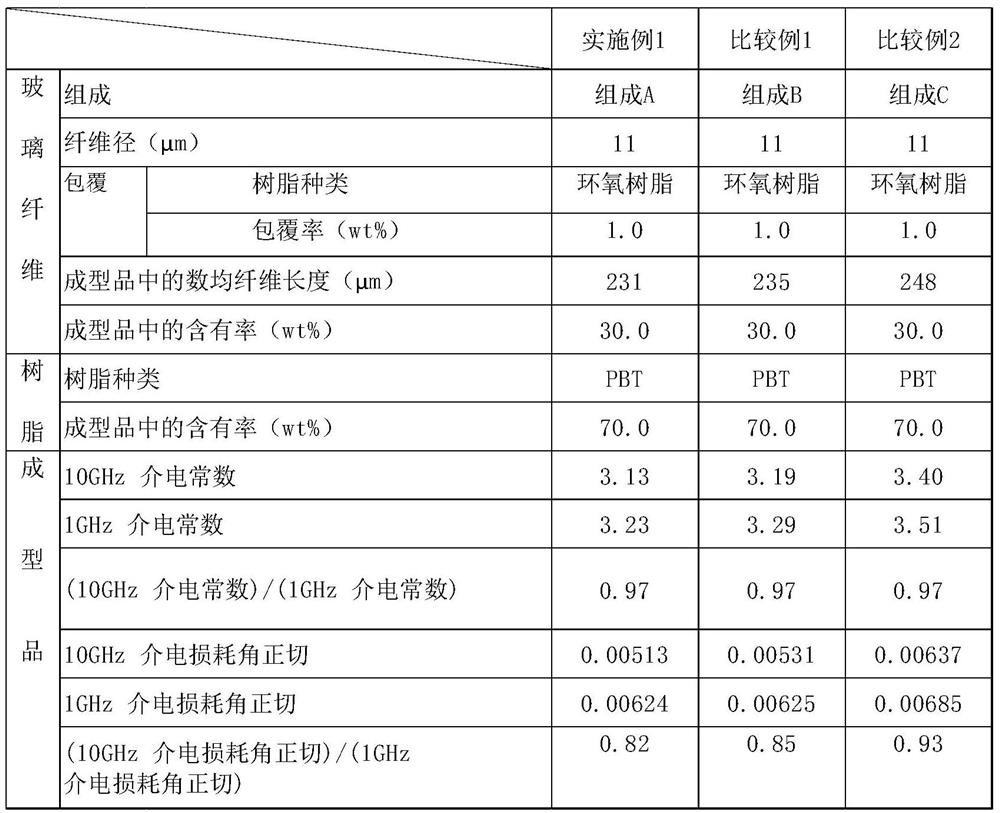

Embodiment 1、 comparative example 1 and comparative example 2

[0140] As shown in Table 2, the number-average fiber length, dielectric constant, and dielectric loss tangent of the glass fiber reinforced resin molded product (a flat plate with a thickness of 1 mm) were evaluated by the method described above. Here, the glass fiber-reinforced resin molded article was obtained as follows: As shown in Table 2, a twin-shaft kneader (manufactured by Toshiba Machine Co., Ltd., trade name: TEM-26SS) was used to prepare the composition A and the composition A respectively. Resin pellets were prepared by kneading glass fiber chopped strands with a fiber length of 3 mm and PBT in B or composition C, and using the obtained resin pellets, an injection molding machine (manufactured by Nisshin Plastic Industry Co., Ltd., trade name: NEX80) by injection molding to obtain the glass fiber reinforced resin molded article.

[0141] Table 2

[0142]

[0143] As shown in Table 2, it can be seen that the glass fiber-reinforced resin molded article of Example ...

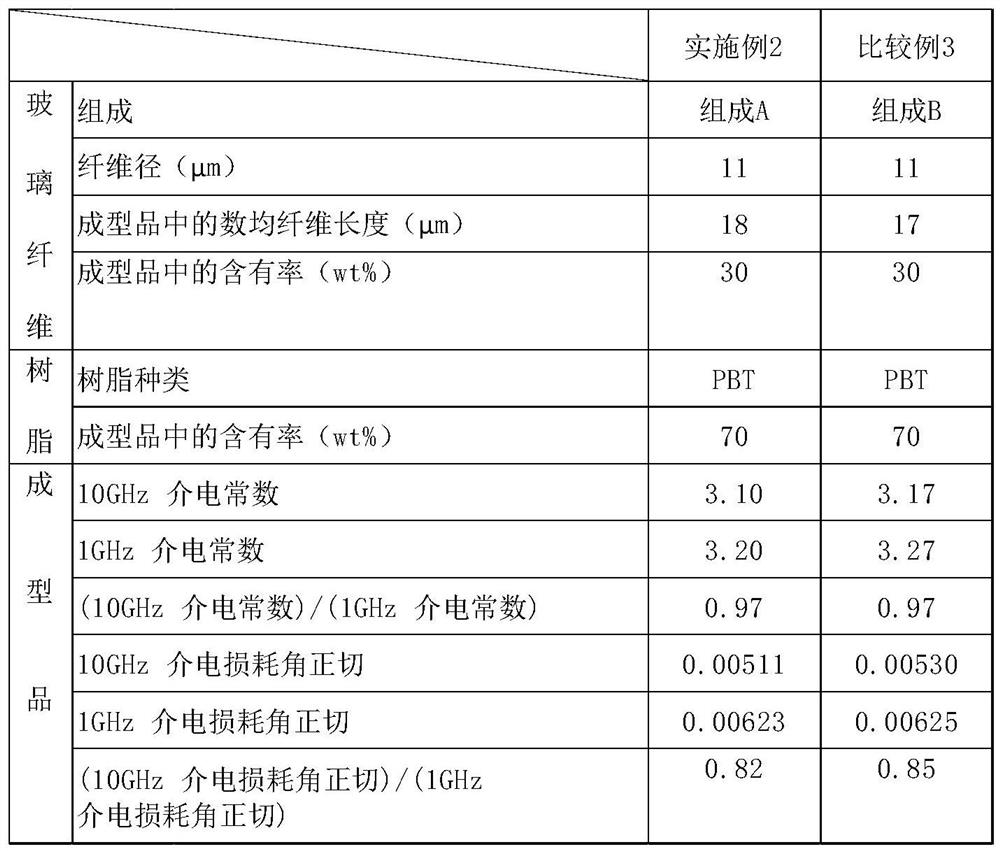

Embodiment 2

[0144] (Example 2, Comparative Example 3)

[0145] As shown in Table 3, the number-average fiber length, dielectric constant, and dielectric loss tangent of the glass fiber reinforced resin molded product (a flat plate with a thickness of 1 mm) were evaluated by the method described above. Here, the glass fiber-reinforced resin molded article was obtained by mixing each of the above-mentioned composition A with a twin-shaft kneader (manufactured by Toshiba Machine Co., Ltd., trade name: TEM-26SS) as shown in Table 3. Cut fibers with a fiber length of 0.030 mm, or cut fibers with a fiber length of 0.030 mm having the above-mentioned composition B (it should be noted that the cut fibers with the above-mentioned composition B can have a fiber length in the range of 0.001 to 0.300 mm), and PBT Kneading was carried out to form resin pellets, and the obtained resin pellets were used to perform injection molding with an injection molding machine (manufactured by Nissin Plastic Indust...

Embodiment 3、 comparative example 4

[0149] As shown in Table 4, the number-average fiber length, dielectric constant, and dielectric loss tangent of the glass fiber reinforced resin molded product (a flat plate with a thickness of 1 mm) were evaluated by the method described above. Here, the glass fiber-reinforced resin molded article was produced as follows: As shown in Table 4, a twin-shaft kneader (manufactured by Toshiba Machinery Co., Ltd., trade name: TEM-26SS) was used to pair the components having the composition A or the composition A respectively. In B, glass fiber chopped strands with a fiber length of 3 mm and PEEK were kneaded to form resin pellets, and the obtained resin pellets were used for injection molding machine (manufactured by Nisshin Plastic Industry Co., Ltd., trade name: NEX80). The above glass fiber reinforced resin molded article was obtained by injection molding.

[0150] Table 4

[0151]

[0152] As shown in Table 4, it can be seen that the glass fiber reinforced resin molded art...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com