Dynamic compensation method of abrasion of grinding wheel of numerical control horizontal shaft surface grinding machine

A dynamic compensation, surface grinder technology, applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc. Give full play to CNC technology and other issues to achieve the effect of simplifying calculation problems and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The content of the present invention will be further described below with an embodiment.

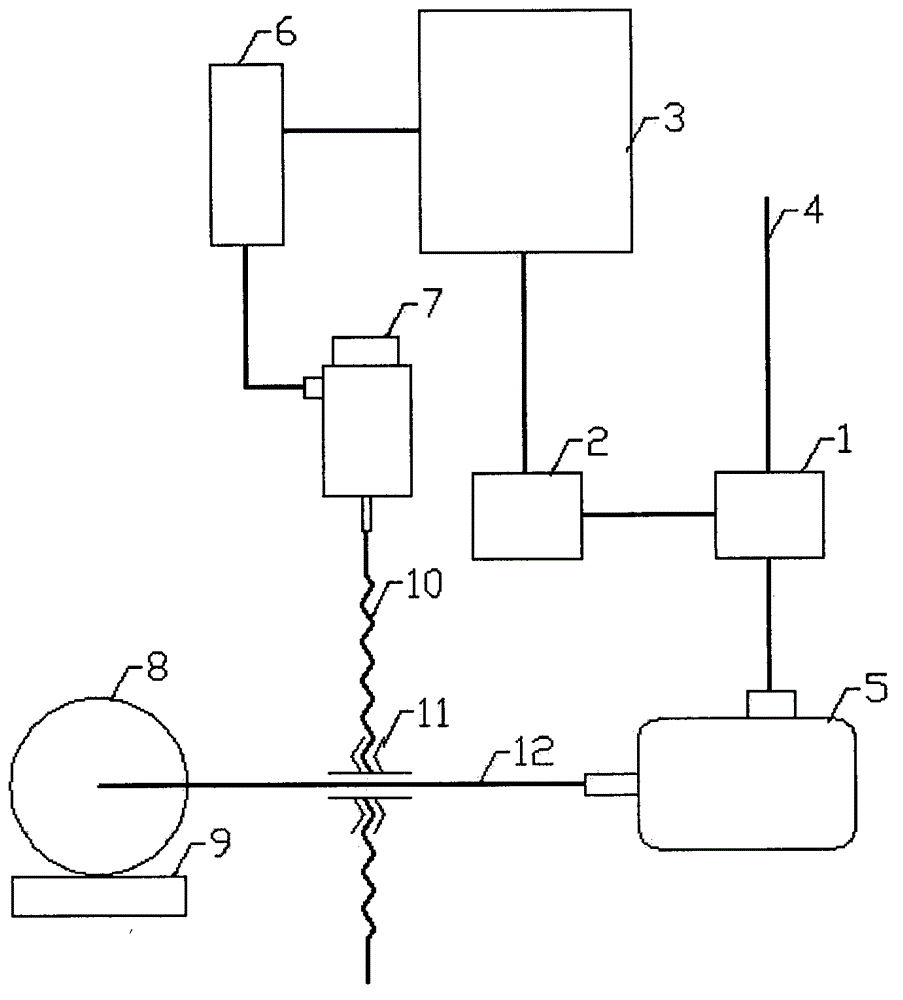

[0094] A common CNC surface grinder with horizontal axis and rectangular table. The vertical moving axis of the grinding wheel is the Y axis. The Y axis is controlled by the servo motor 7 through the reducer to rotate the ball screw 10. The ball screw drives the screw nut and the grinding wheel supporting mechanism connected with the nut. 11 Move up and down; the horizontal movement axis of the worktable is the Z axis, the Z axis is controlled by the servo motor through the reducer to rotate the ball screw, the ball screw drives the screw nut and the sliding seat connected to the nut to move, and the sliding seat supports the workbench for horizontal movement. Movement; the longitudinal movement axis of the workbench is the X-axis, and the X-axis is pushed by the push rod of the hydraulic cylinder to move the workbench on the sliding seat to move longitudinally; the motor of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com