Method for correcting measurement vibration of deformation video of multi-constrained wind tunnel test model

A technology of wind tunnel test and model deformation, applied in video measurement and vibration correction of wind tunnel test model deformation, engineering application field of machine vision measurement technology in high-speed wind tunnel test, can solve the difference of correction results, not fully utilizing measurement features, Problems such as the overall offset of the camera coordinate system cannot be corrected to achieve the effect of simplifying the iterative equation and calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Technical scheme of the present invention is:

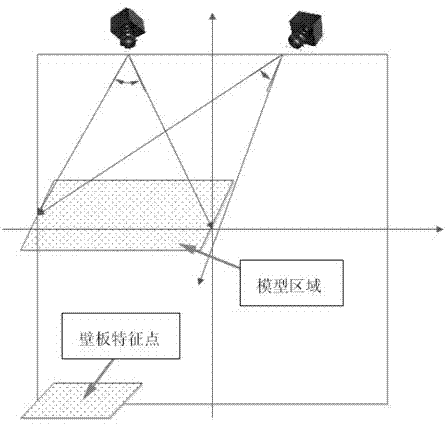

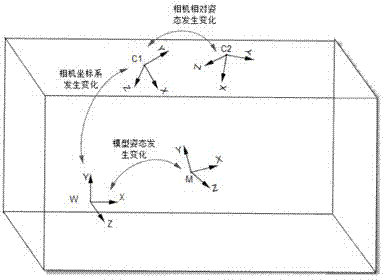

[0020] First, perform intersection imaging on the wind tunnel test model according to the measurement principle of stereo vision; calibrate the system before the test; during the test, it is assumed that internal parameters such as the focal length, distortion, and image principal point of the camera remain fixed; at the same time, it is assumed that Affected by the on-site airflow and vibration, the attitudes of the observation camera and the test model are offset relative to the coordinate system of the test section.

[0021] Second, take the three-dimensional initial coordinates of all characteristic marker points in the zero state of the test model as a reference when the test model is in the static state, and regard the test model fuselage and the test section wall as two independent rigid bodies, and the three-dimensional relative positions of the characteristic marker points during the test The coordinates remain fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com