Heat distortion compensation method of digial controlled machine tool main driving system

A main drive system, CNC machine tool technology, applied in automatic control devices, metal processing mechanical parts, metal processing and other directions, can solve the problems of poor accuracy stability, many accessory parts, poor accuracy and accuracy stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

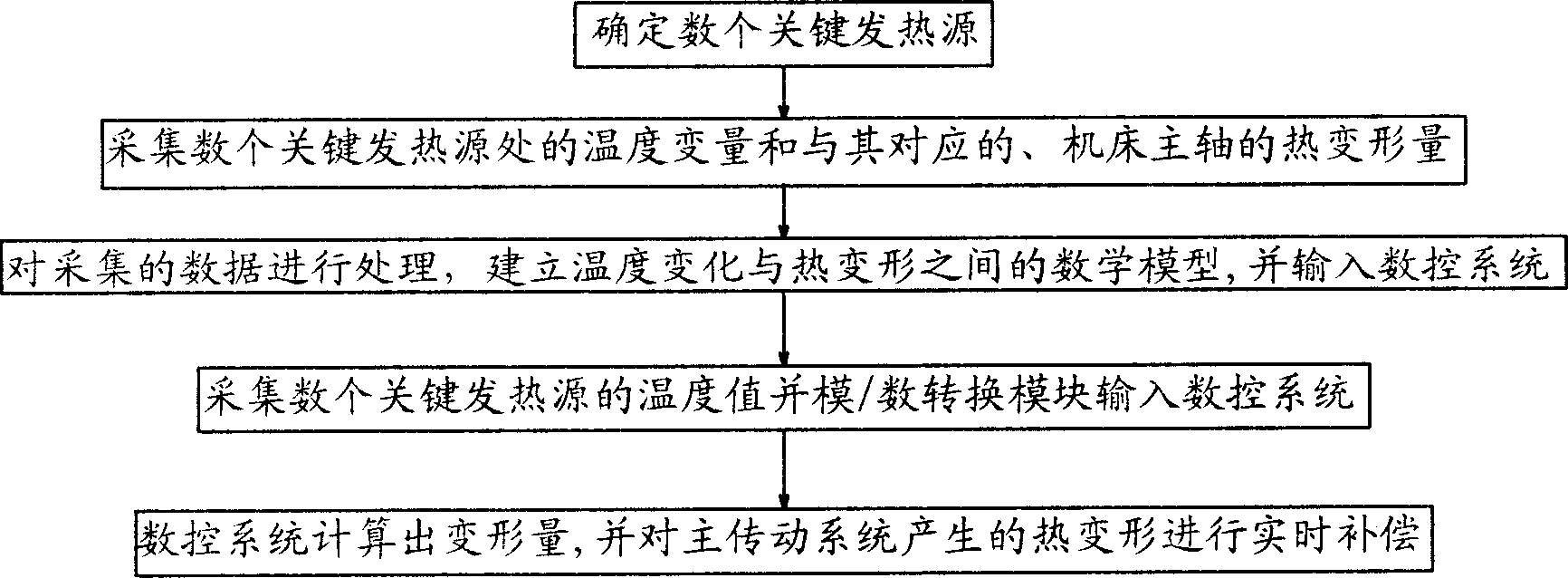

Method used

Image

Examples

Embodiment 1

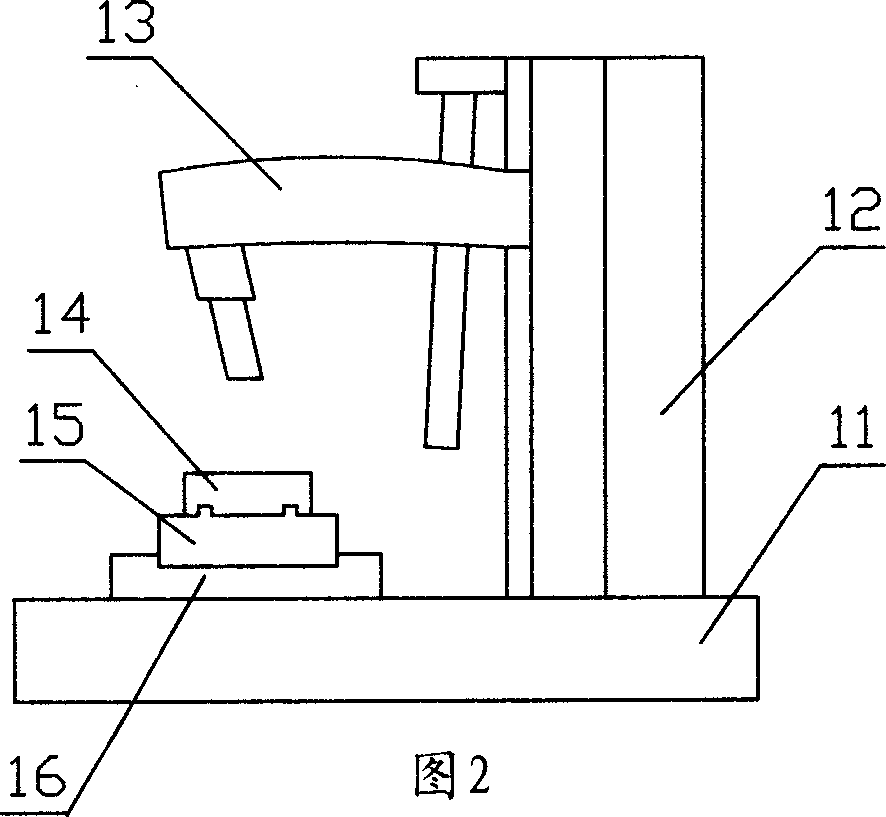

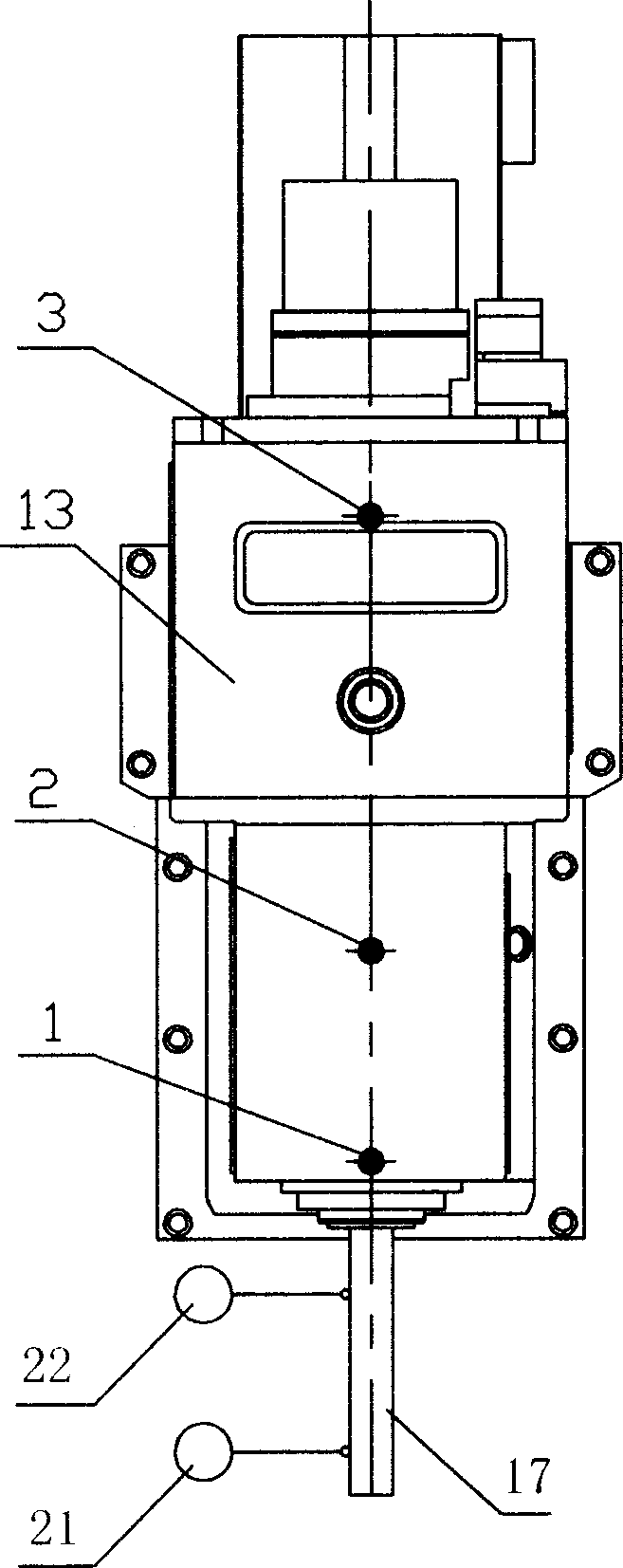

[0131] 2. By setting two temperature sensors 3, 1 (PT100 type platinum thermistor) respectively on the main shaft housing 13 corresponding to the upper and lower bearing pairs of the main shaft, as Figure 5 , as shown in Figure 6, a standard inspection mandrel 17 is installed on the main shaft, and two dial gauges 23 and 24 with a distance of 250 mm are respectively installed in the YZ plane, and the contacts of the dial gauge are aligned with the center of the standard inspection mandrel 17 Line and align to zero, install a dial indicator 25 on the end face of the main shaft, respectively collect the temperature variables at the two key heat sources and the corresponding thermal deformation of the machine tool main shaft in the Y direction and Z direction at this moment;

[0132] After starting the machine tool, the machine tool spindle starts to run step by step from low speed to high speed. At a fixed time interval, check and record the two temperature variables and the the...

Embodiment 2

[0142] 2. By setting the three temperature sensors 1, 3, 5 respectively on the lower bearing pair corresponding to the main shaft, the upper bearing pair and the main shaft case of the gearbox, such as Figure 5 , as shown in Figure 6, a standard inspection mandrel 17 is installed on the main shaft, and two dial gauges 23 and 24 with a distance of 250 mm are respectively installed in the YZ plane, and the contacts of the dial gauge are aligned with the center of the standard inspection mandrel 17 line and zero, a dial indicator 25 is installed on the end face of the main shaft, and the temperature variables at the three key heat sources and the corresponding thermal deformations of the main shaft of the machine tool in the Y direction and Z direction are collected respectively; Embodiment one is identical;

[0143] 3. Use the method of multiple linear regression to process the temperature variable and thermal deformation collected in step (2), and establish the mathematical re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com