Trajectory regeneration compensation method of numerical control machine error

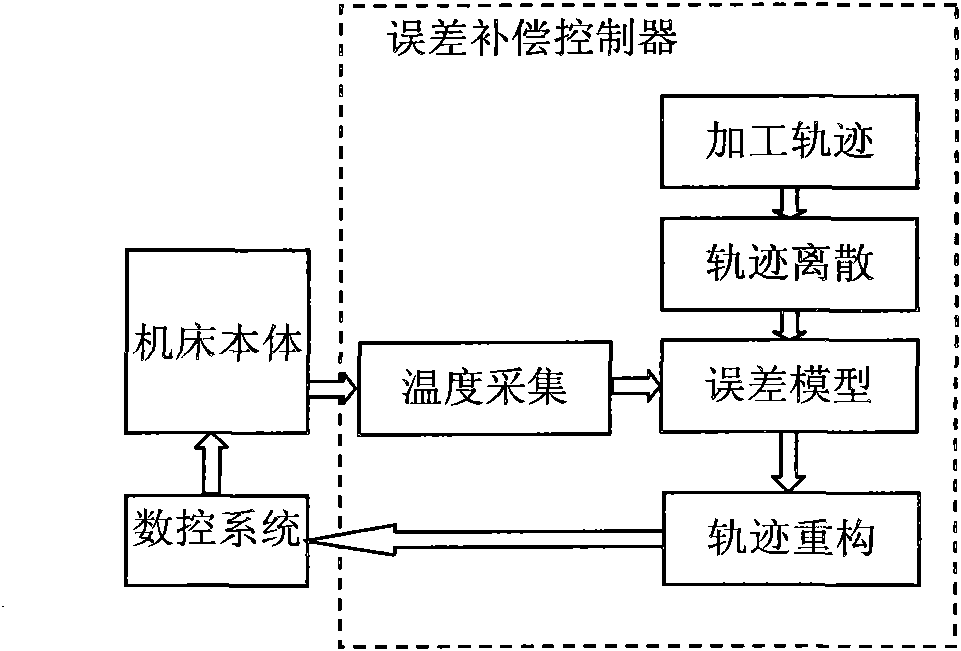

A technology of numerical control machine tool and compensation method, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of limited compensation error, complex calculation and processing, and consumption of computing resources, so as to compensate thermal error, improve machining accuracy, Modular good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

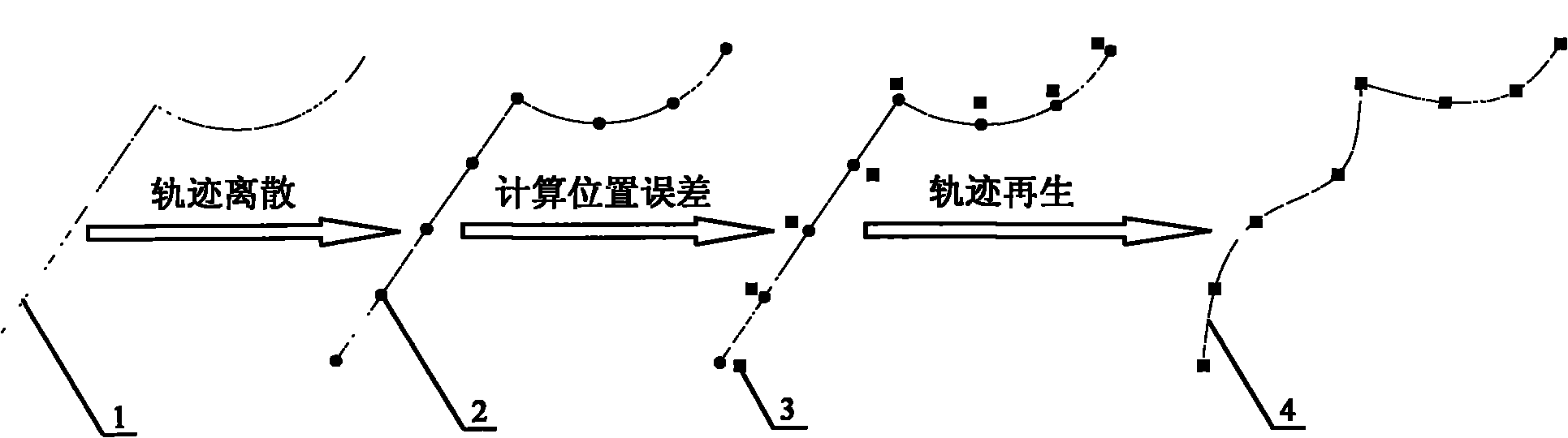

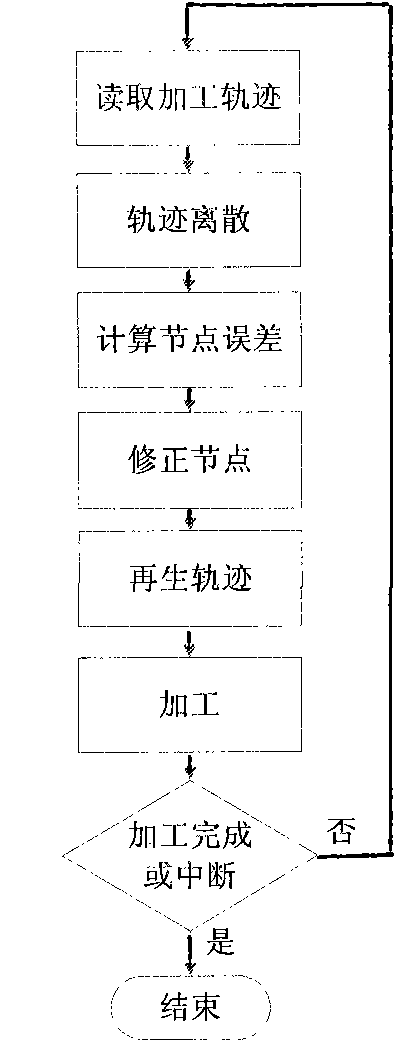

Method used

Image

Examples

Embodiment

[0047] A typical implementation example of the present invention is as follows:

[0048] 1. Obtain the geometric error and thermal error data, and use the least square method to establish the machine tool error model;

[0049] The CNC milling machine 4300C is selected as the experimental machine tool. The overall geometric error of the machine tool is measured by a laser interferometer, mainly measuring the positioning error and repetitive positioning error of the three axes. The thermal error mainly measures the overall thermal deformation of the machine tool caused by the heating of the machine tool spindle. The thermal deformation is collected by three CCD laser displacement sensors (LK-150H), and the temperature is collected by thermocouples. Measure the thermal deformation data of the Z-axis, X-axis, and Y-axis from the temperature field data of the machine tool at a spindle speed of 5000 rpm when the CNC milling machine is unloaded. Data sampling is performed every 0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com