Drilling and lead inserting system for assembling firework

A technology of fireworks and punching needles, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of low insertion and extraction success rate, low technical maturity of technical solutions, and difficulty in application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

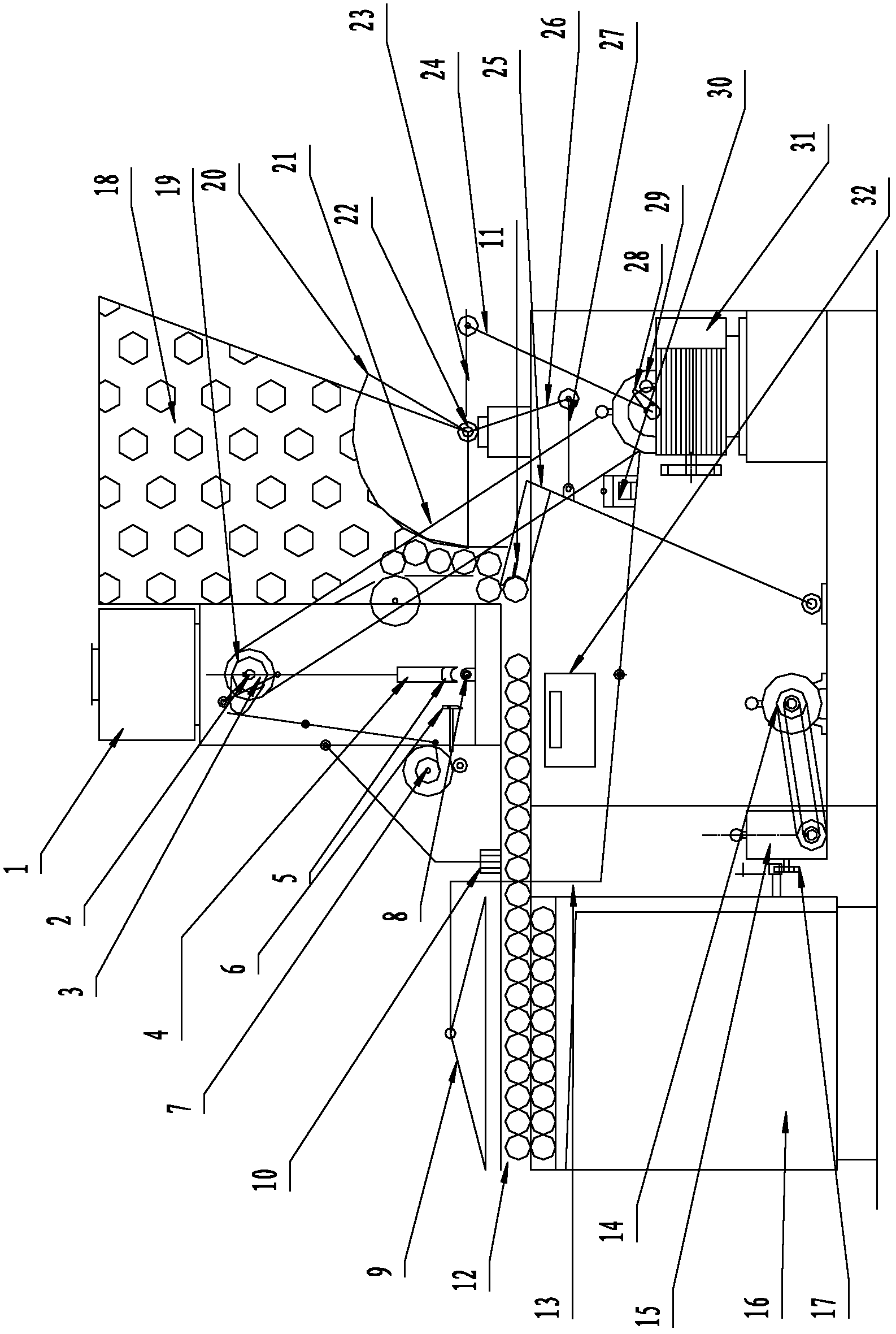

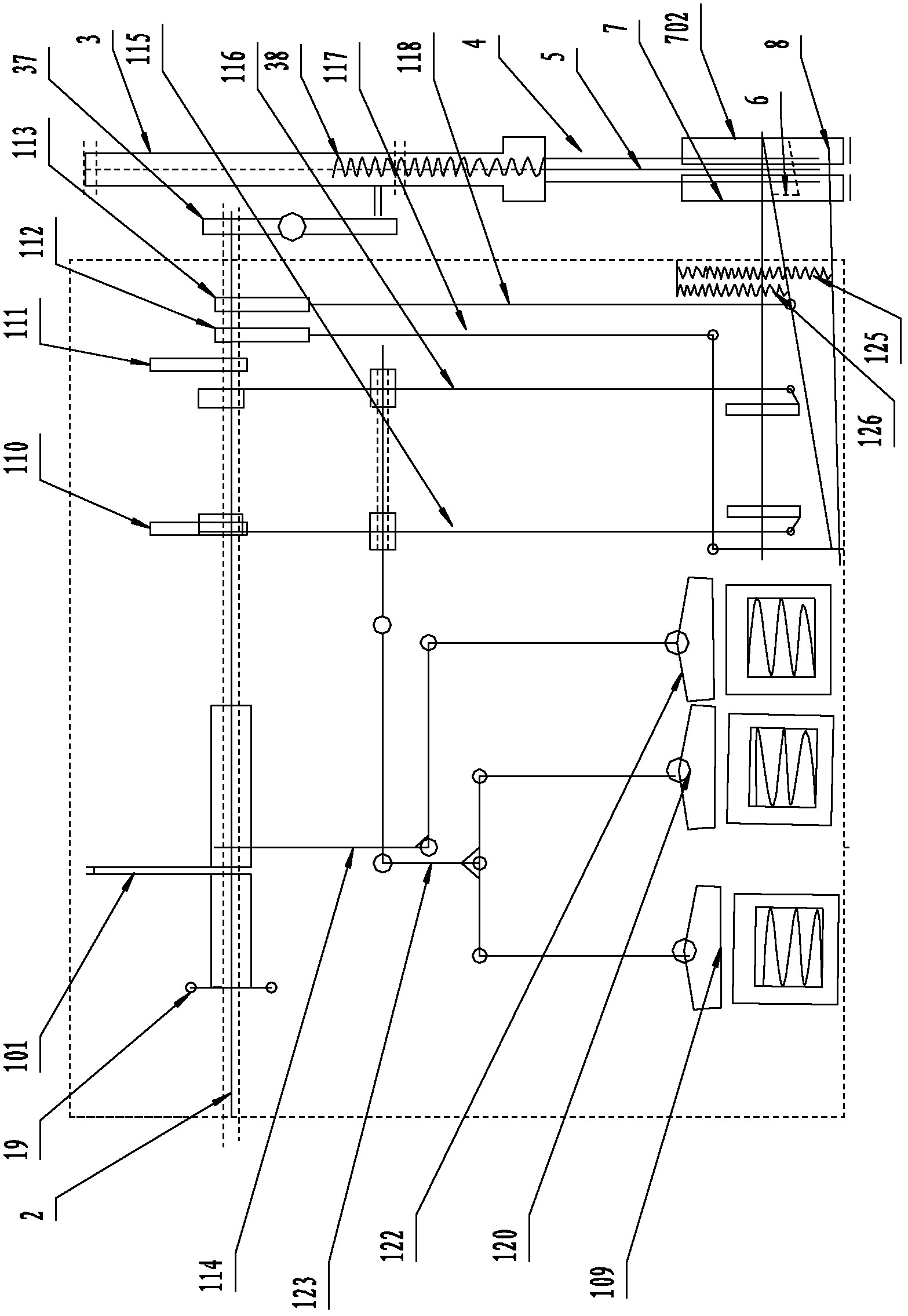

[0020] As a preferred specific structure, the fireworks numerical control assembly machine is composed of a feeding system, a punching and insertion system, a forming system, a numerical control system, and a drive transmission system installed on the frame:

[0021] The feeding system includes a hopper on the upper part of the frame, the lower outlet of the hopper is connected to the conveying lane, the lower outlet of the hopper is equipped with a distribution wheel and a feeding rod, the front end of the feeding rod is installed on the top of the conveying lane, and the upper rubber brush is connected to the feeder. glue device;

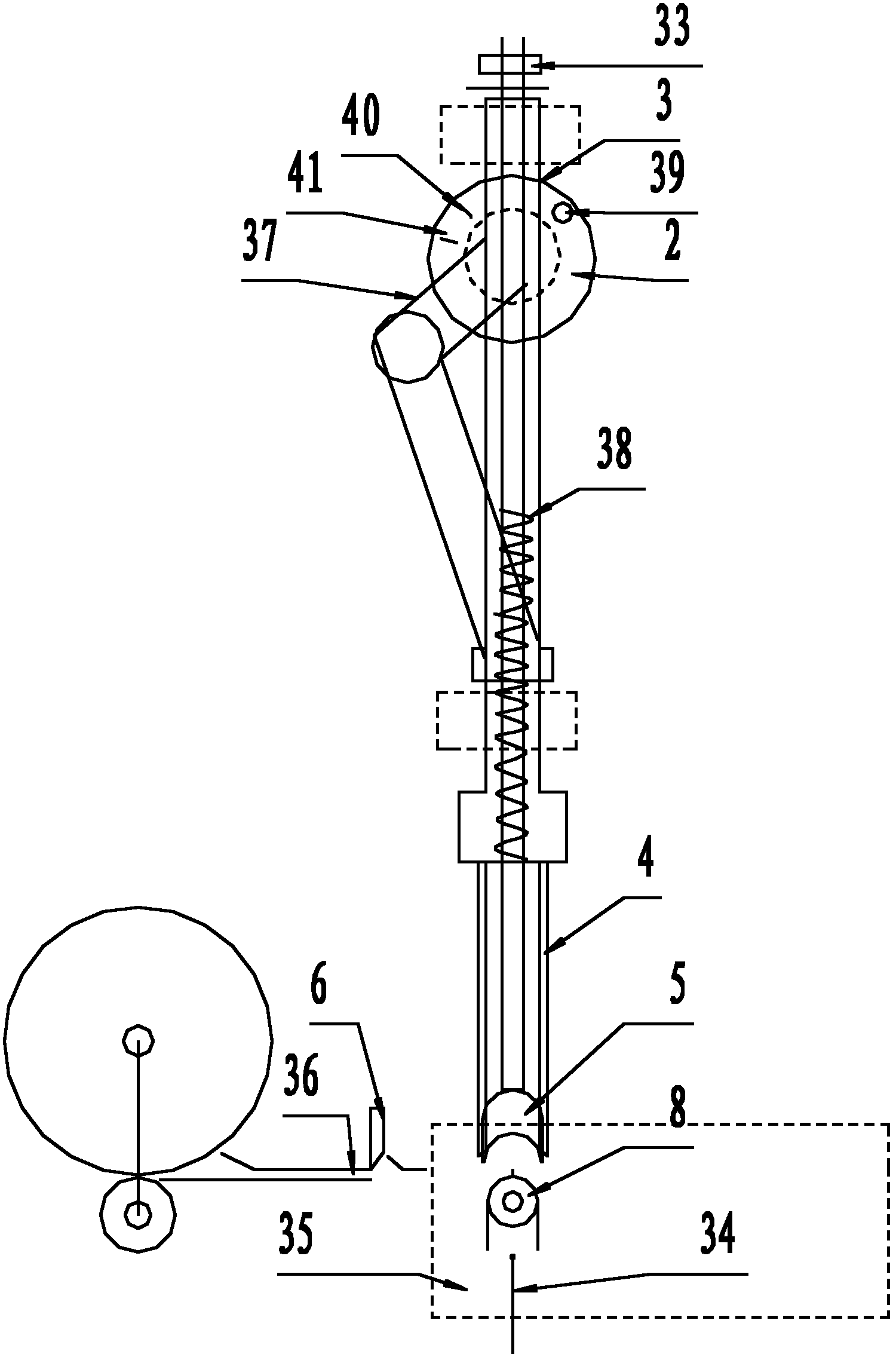

[0022] The perforating and inserting system device is above the conveying lane, including a needle bar that can move back and forth up and down; the lower end of the needle bar is equipped with a "∏"-shaped perforating and inserting device composed of two perforating needles parallel to each other. There is a guide groove on the opposite inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com