Method and device of disposing holes on carbon fiber composite material and meal material which are overlapped

A technology of composite materials and metal materials, which is applied in the field of high-quality hole-making in the laminated assembly of carbon fiber composite materials and metal materials, to reduce production costs and cycle times, improve processing quality and efficiency, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

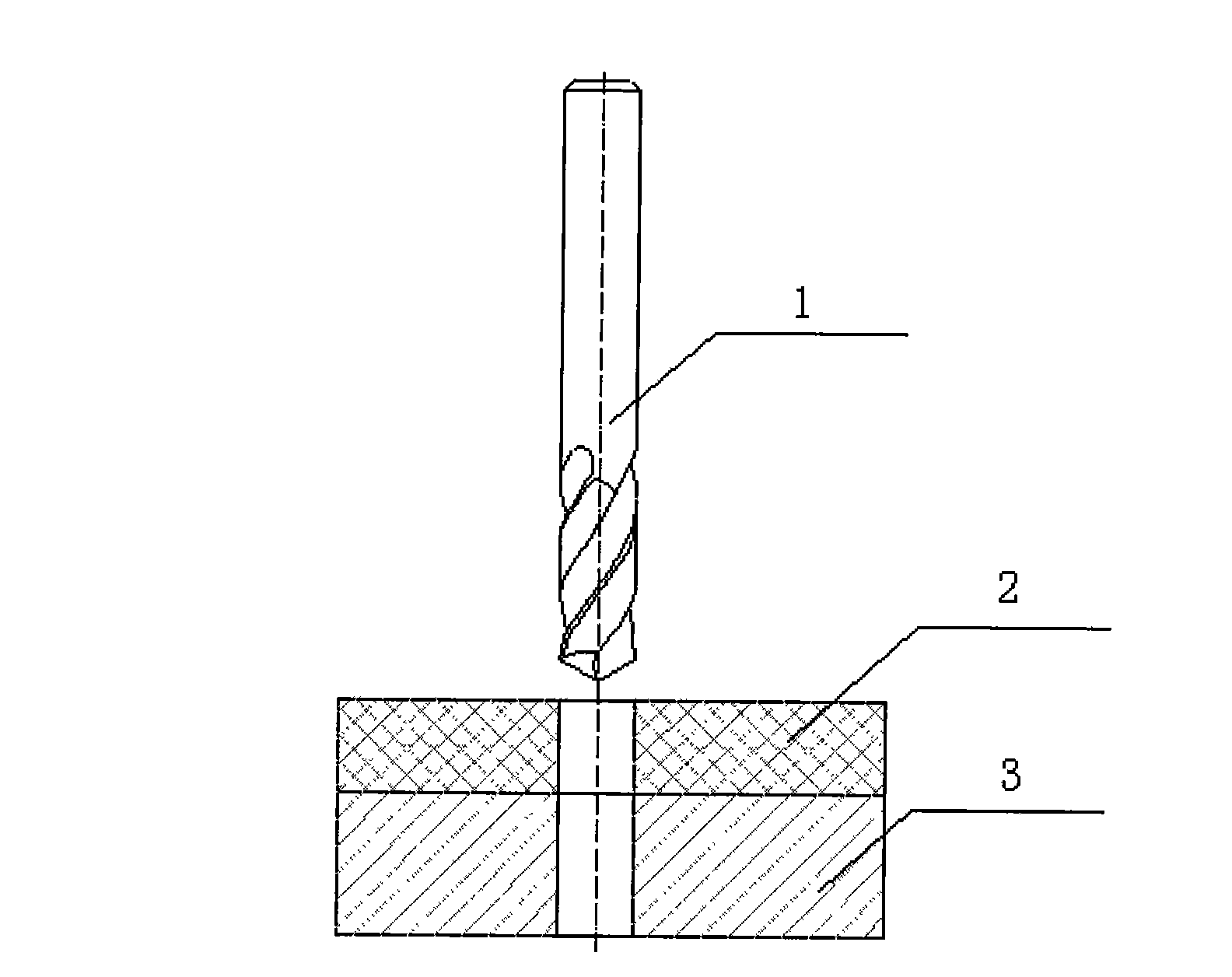

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

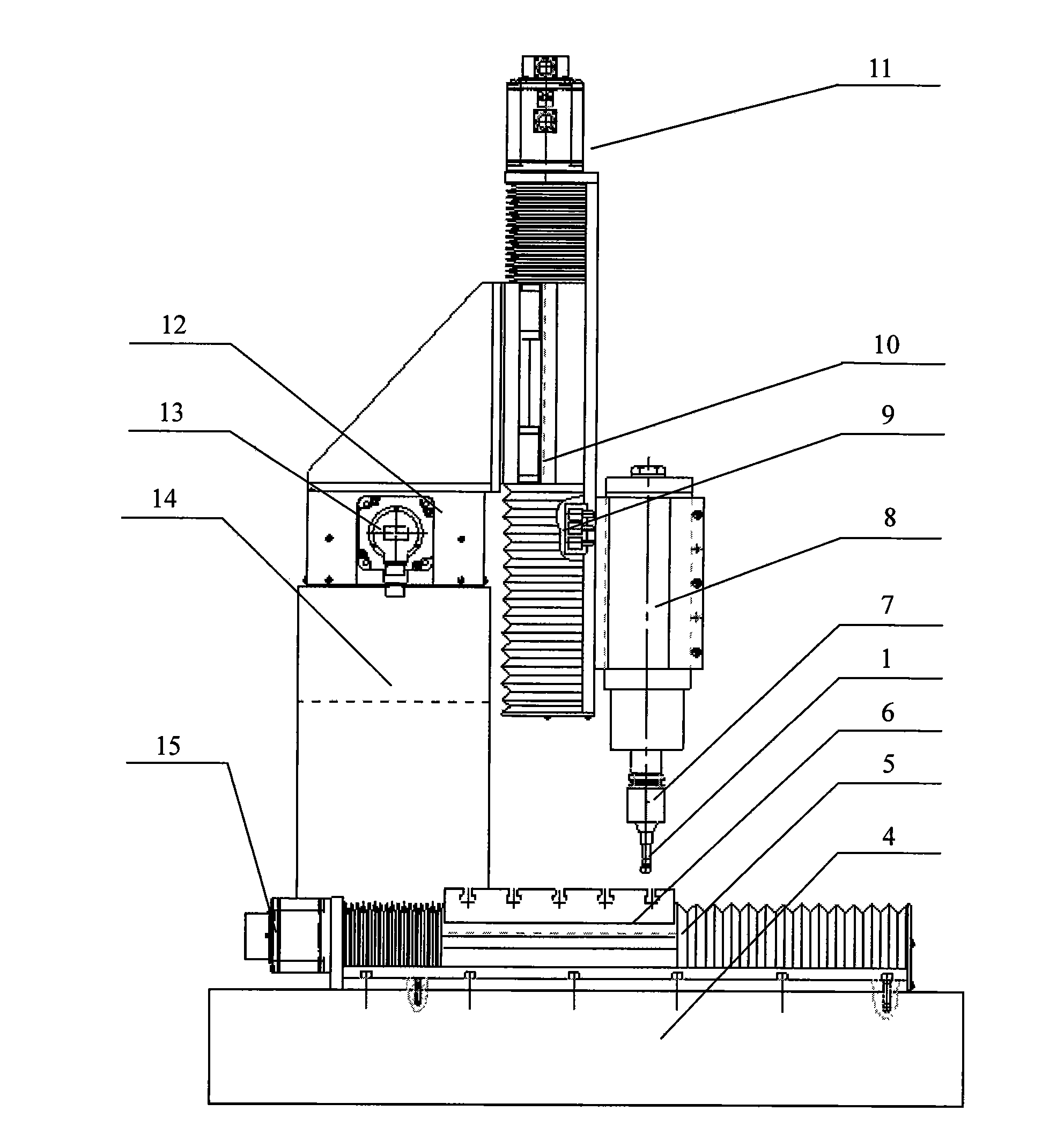

[0020] attached figure 2 is an embodiment of the present invention. Such as figure 2Shown is a schematic diagram of a carbon fiber composite material and metal material laminated assembly hole making device. The hole making tool 1 is installed on the handle 7, the handle 7 is installed on the electric spindle 8, the electric spindle is held on the vertical feed slide 10, and the vertical feed slide 10 is driven by the vertical feed motor 11 to make the The hole tool 1 makes a vertical feed motion; the tool drilling motion is driven by the electric spindle 8 .

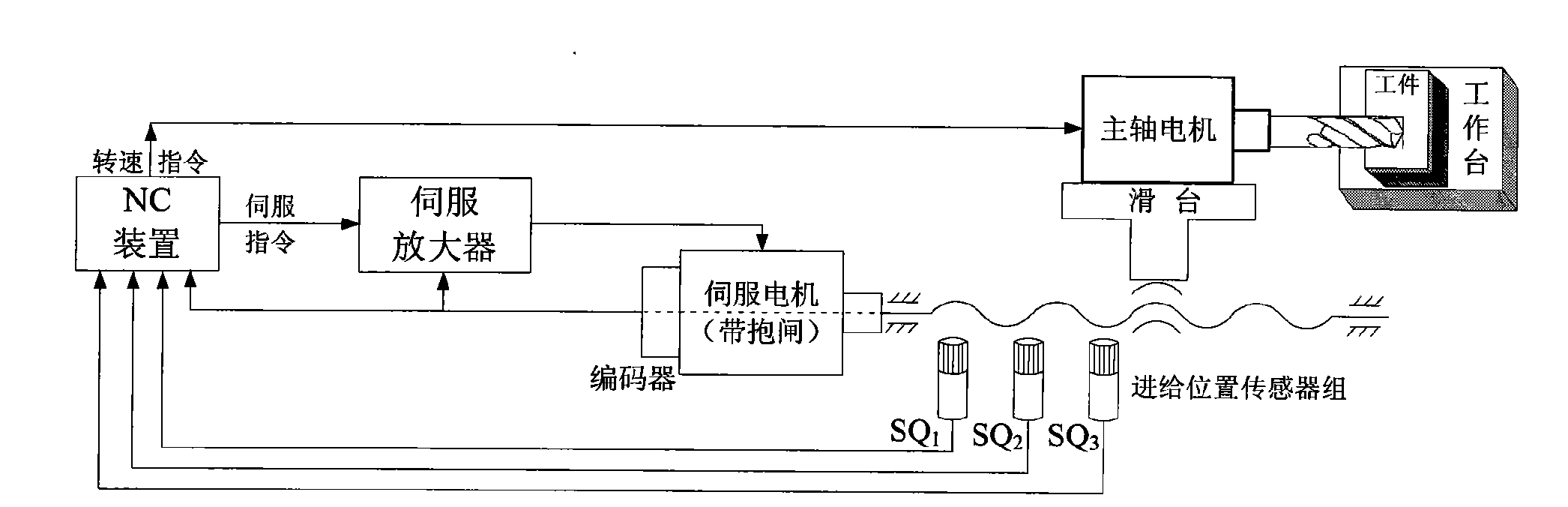

[0021] as attached image 3 And attached Figure 4 As shown, the numerical control system for the feed motion of the drilling device is composed of a numerical control system, a servo amplifier, a feed servo motor, a feed position sensor group, and a feed motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com