Numerical control machine tool double-shaft synchronization controller

A synchronous control, numerical control machine tool technology, applied in the numerical control field, can solve the problem that the popular numerical control system cannot realize the synchronous control and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

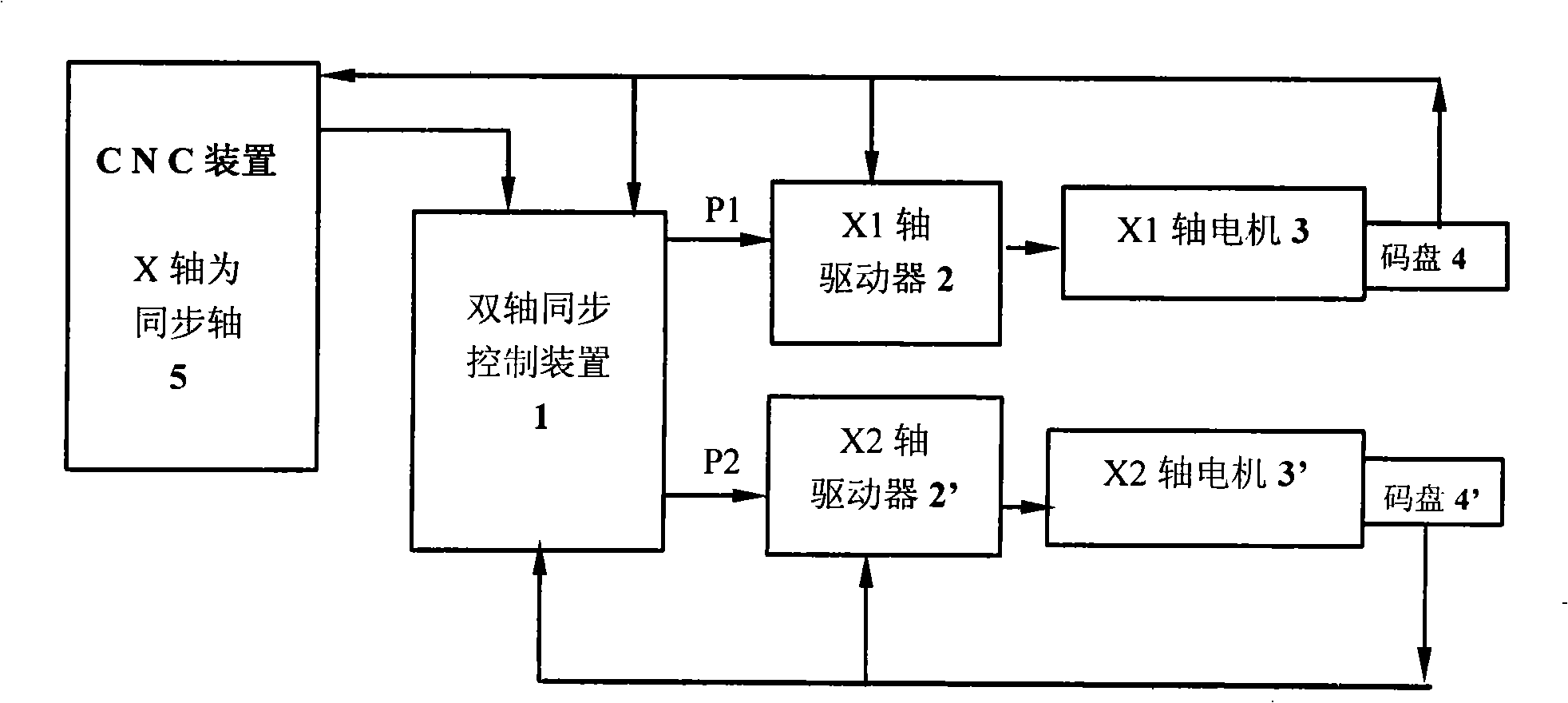

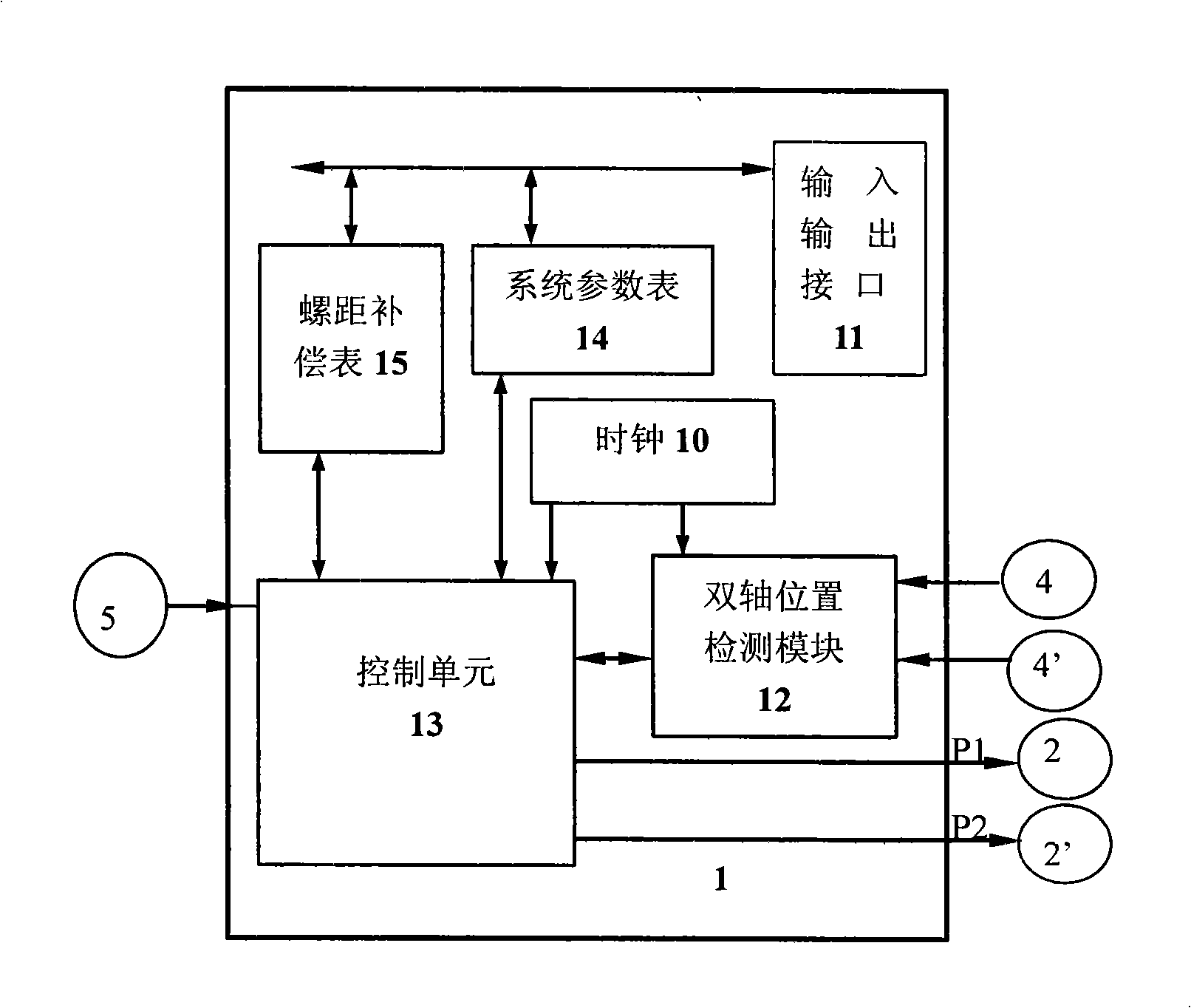

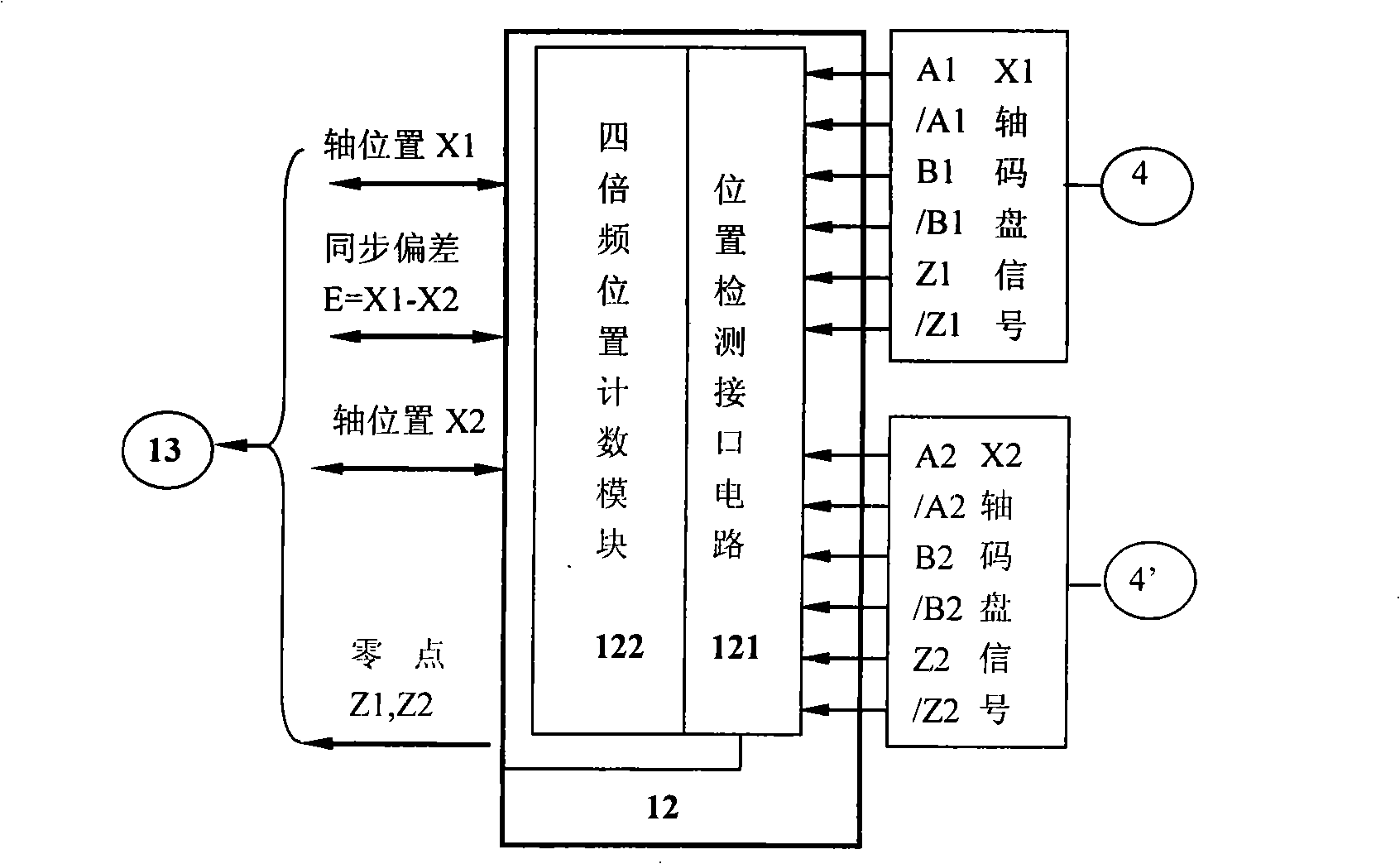

[0033] The basic principle of the dual-axis synchronous control device of the CNC machine tool is: after the synchronous control device receives the CNC pulse command, it forwards it to the two synchronous synchronous axes (X1 axis and X2 axis, X axis is taken as an example in the text) in real time, and at the same time Count the position feedback signals of the two axes, and calculate the position deviation of the two synchronous axes, and adjust the number of pulses of the driven axis (X2 axis) within a certain range according to the deviation, so as to realize the output position of the two motors synchronous control. Below in conjunction with accompanying drawing and example the present invention is described in further detail.

[0034] Such as figure 1As shown, it is a block diagram of the connection between the dual-axis synchronous control device of the CNC machine tool and the numerical control system; after adding the dual-axis synchronous control device 1, for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com