Automatic micro-droplet array screening system using method with pico-liter-scale precision

A micro-droplet and drive system technology, applied in chemical instruments and methods, laboratory equipment, laboratory containers, etc., can solve problems such as difficult to use screening systems, difficult to industrialize instruments, difficult to realize automation, etc., to achieve improved Throughput, reduced risk of cross-contamination, effect on reduced sample/reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

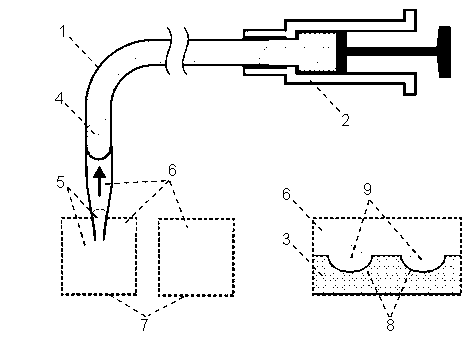

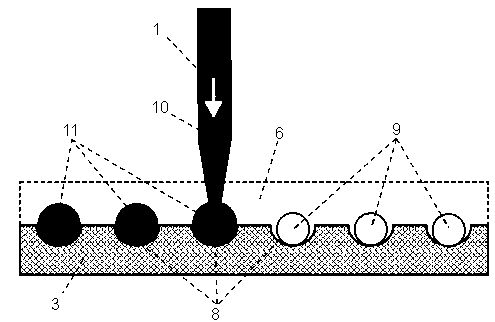

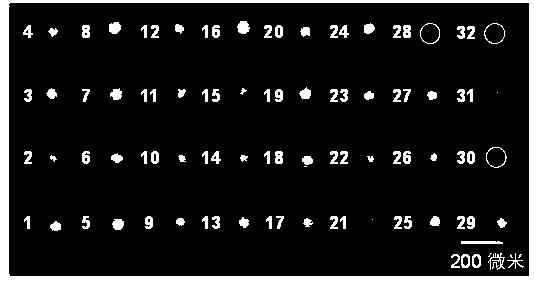

[0058] image 3 is based on figure 1 and figure 2 The liquid droplet array screening system and its use method use 32 small molecule chemicals as the samples to be screened, and Caspase-1 enzyme as the screening target to carry out the fluorescence pictures obtained by screening enzyme inhibitors. Start by loading 100 µM of small molecule compounds into sample / reagent storage tubes. use figure 1 The droplet array generation method generates 32 droplets of small molecule chemicals on the microwell array chip, and the volume of each droplet is 180 picoliters. then follow figure 2 In the target reagent injection method, 180 picoliters of Caspase-1 enzyme solution (6 mU / μL) and 180 picoliters of substrate (Z-YVAD-R110) solution (20 μM) were injected into each droplet to trigger a reaction. The microwell array chip was incubated at 35 degrees Celsius for 1 hour, and the experimental results were obtained by fluorescence imaging. Analyzing the experimental results, the stro...

Embodiment 2

[0061] Figure 4 is true image 3 The result recording chart of Caspase-1 enzyme half-inhibition concentration determination of No. 28 compound obtained in the screening experiment. First, fill the sample / reagent storage tubes with compound No. 28 solutions at concentrations of 0.1 nM, 1 nM, 10 nM, 100 nM, 1 μM, 10 μM, and 100 μM, respectively. according to figure 1 and figure 2In the droplet array screening system and method of use, droplets (180 picoliters) containing different concentrations of compound No. 28 solutions are generated on the microwell array chip, and then 180 picoliters of Caspase-1 is injected into each droplet Enzyme solution (6 mU / μL) and 180 pL of substrate (Z-YVAD-R110) solution (20 μM) were used to trigger the reaction. According to the method of Example 1, the resultant fluorescence pictures were obtained, and the fluorescence brightness values were extracted and normalized. The concentration of compound 28 was logarithmically processed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com