Part repairing device based on additive and decreasing manufacturing and application method of part repairing device

A technology of additive manufacturing and parts repair, applied in manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of low degree of automation, low degree of automation, high degree of dependence on manual operation, to improve the degree of automation and high quality repaired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

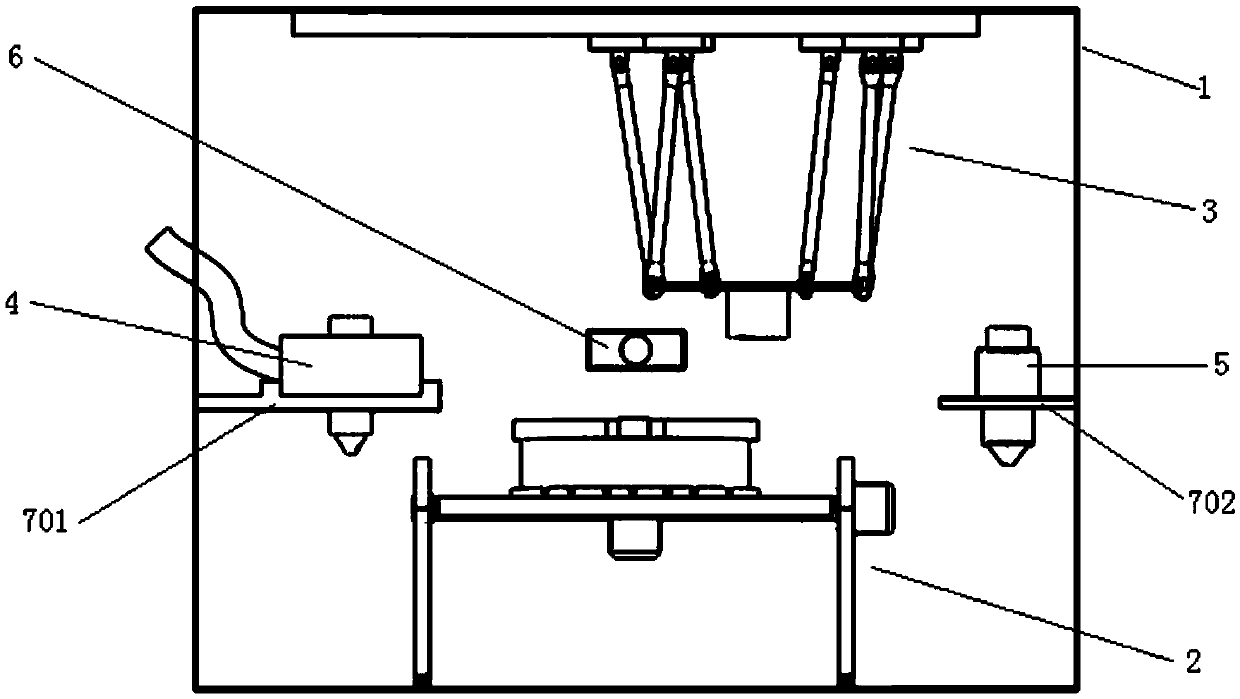

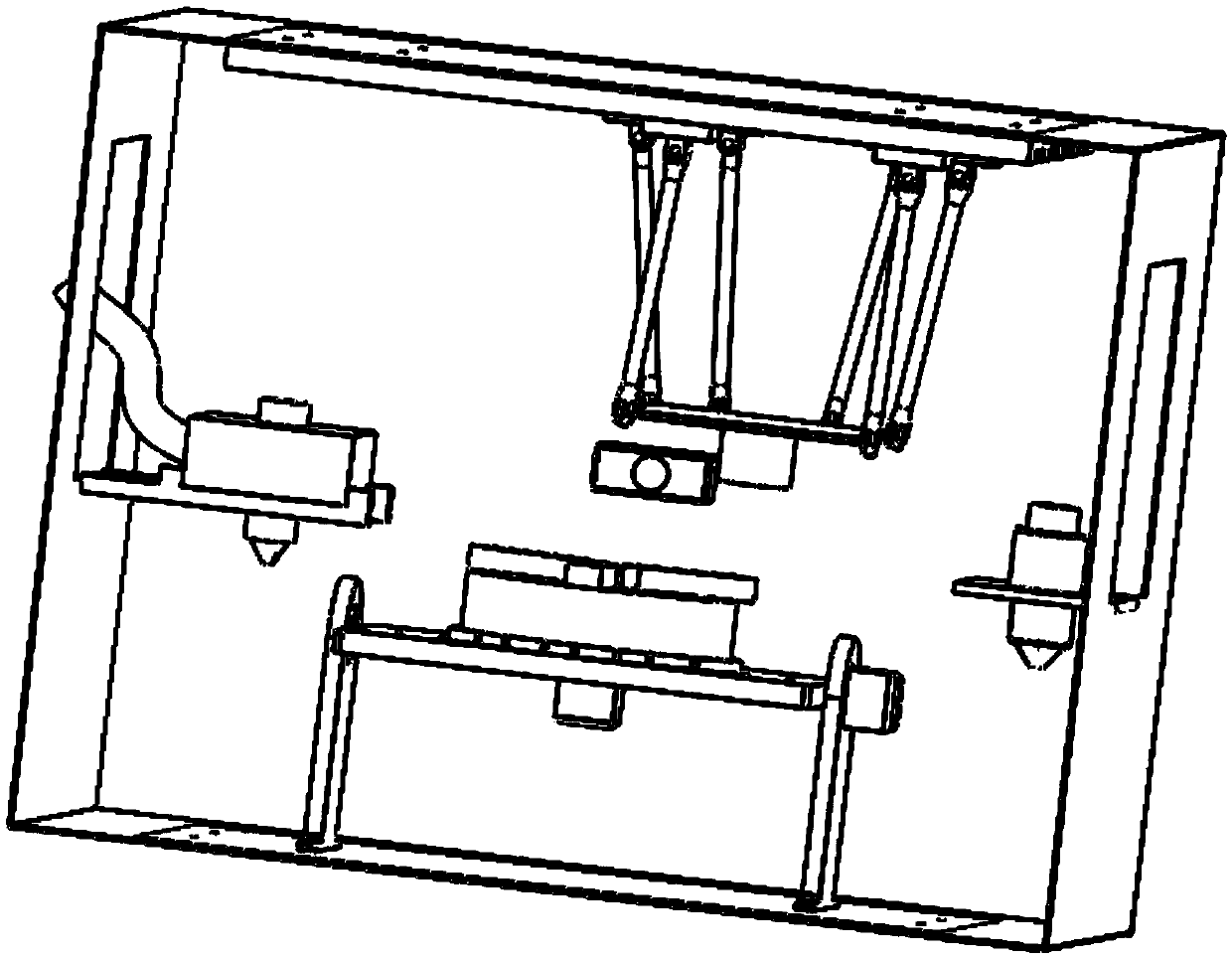

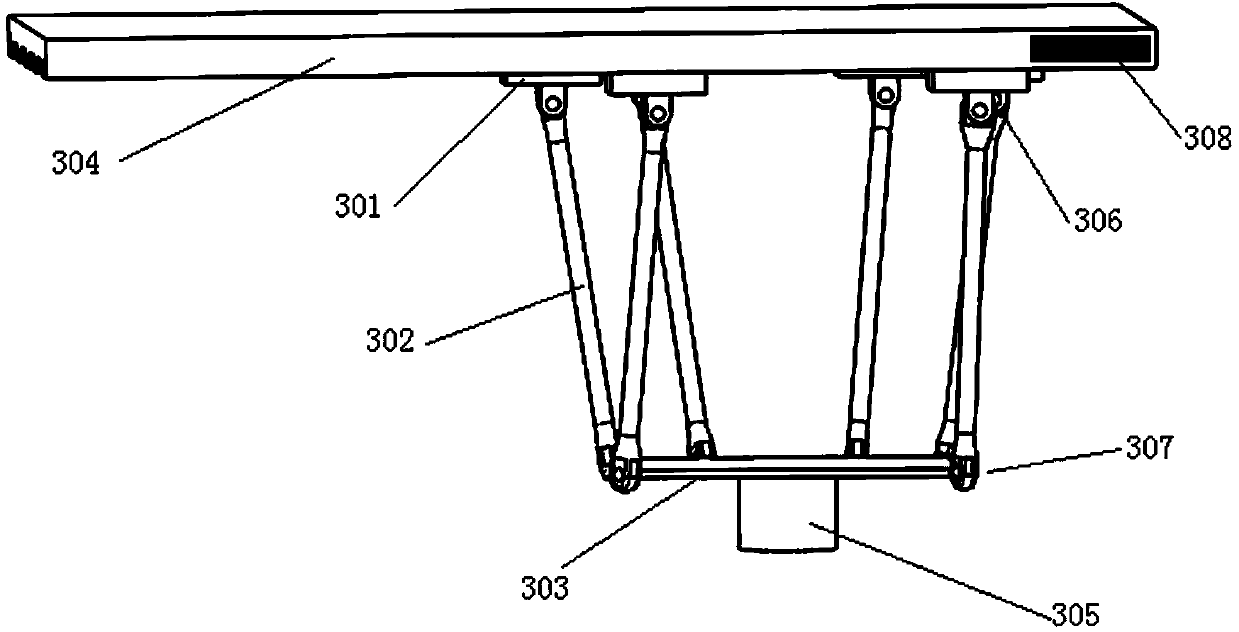

[0086] Such as figure 1 As shown, a parts repair device based on additive and subtractive material manufacturing, including a bed 1 and a workbench 2, is characterized in that: a parallel clamping device 3 is provided on the upper part of the bed 1, and a three-dimensional scanner is provided on the side of the bed 1 6. Additive manufacturing module fixing mechanism 701 and subtractive processing module fixing mechanism 702 . The additive manufacturing module 4 is placed on the additive manufacturing module fixing mechanism 701 . The subtractive processing module 5 is placed on the fixing mechanism 702 of the subtractive processing module. The workbench 2 is located below the parallel clamping device 3 . The three-dimensional scanner 6 is fixed on the rear of the bed 1 . The workbench 2 is located within the scanning range of the three-dimensional scanner 6 . The additive manufacturing module fixing mechanism 701 and the subtractive processing module fixing mechanism 702 a...

Embodiment 2

[0092] Repeat Example 1, except that the distance d between the additive manufacturing module and the central axis of the subtractive manufacturing module is 100 cm.

Embodiment 3

[0094] Repeat embodiment 1, except that the parallel clamping device 3 includes 10 slide tables 301.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com