A system and method for zero-discharge treatment of coal chemical wastewater with electrolytic oxidation and salt separation and crystallization

A technology of electrolytic oxidation and coal chemical industry, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult to obtain industrial-grade crystallization and salt separation, and save Manual inspection link, the effect of close connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

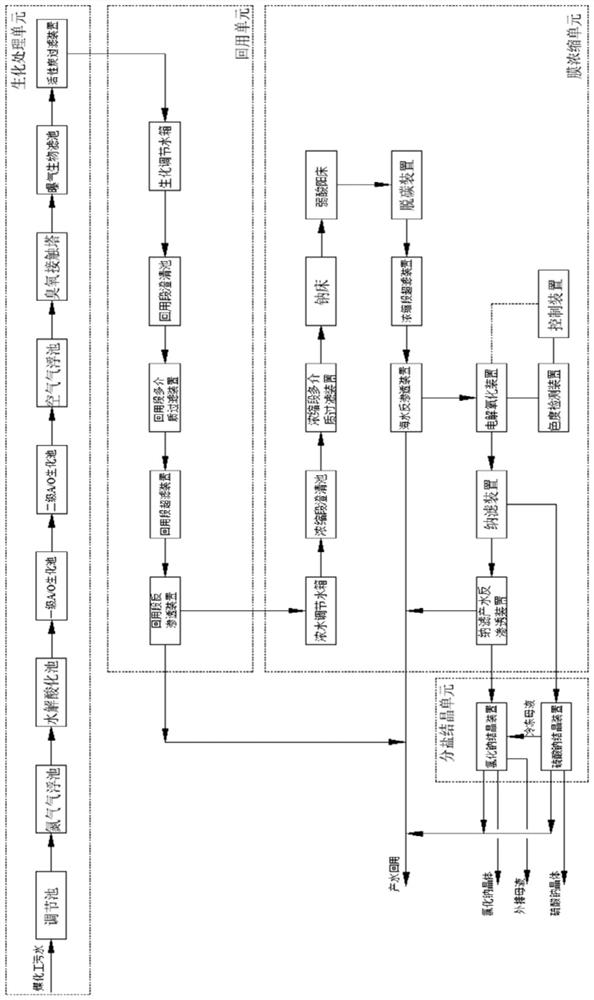

[0070] The treatment system provided by the specific embodiment is used to carry out zero-discharge treatment of coal chemical sewage, and the method includes:

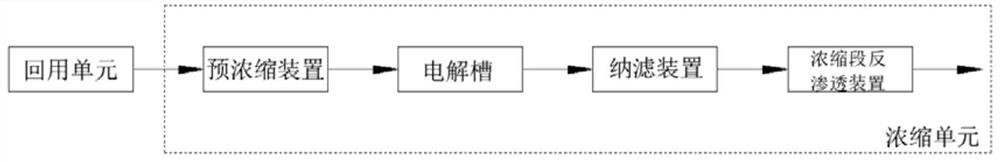

[0071] (I) Coal chemical wastewater passes through the reuse unit and the pre-concentration device in turn to obtain reverse osmosis concentrate;

[0072] (II) The reverse osmosis concentrated water is oxidized by an electrolytic oxidation device to obtain electrolytic oxidation product water;

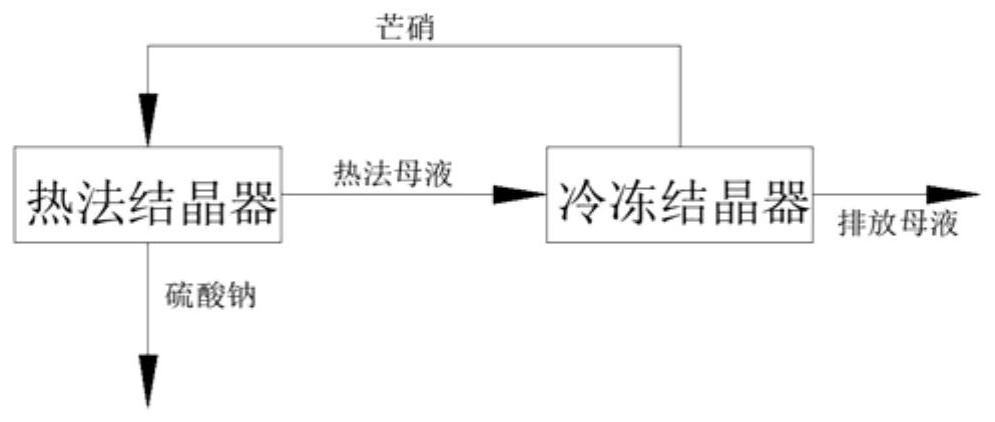

[0073] (III) After the electrolytic oxidation product water is discharged, it passes through the nanofiltration device and the nanofiltration product water reverse osmosis device in turn to obtain concentrated water that can be used for salt separation and crystallization. Among them, the electrolytic oxidation product water is subjected to nanofiltration to obtain nanofiltration concentrated water and nanofiltration product water, the nanofiltration concentrated water is subjected to thermal freezing and crystallization to pr...

Embodiment 2

[0077] The difference between this example and Example 1 is that the electrolysis time of the electrolytic oxidation device in step (II) is 2h, the electrolysis current is 703A, and the remaining steps are the same as those of Example 1.

[0078] Measured COD in electrolytic oxidation product water Cr Content and NH 3 -N content is shown in Table 1.

Embodiment 3

[0080] The difference between this example and Example 1 is that the electrolysis time of the electrolytic oxidation device in step (II) is 4h, the electrolysis current is 600A, and the remaining steps are the same as those in Example 1.

[0081] Measured COD in electrolytic oxidation product water Cr Content and NH 3 -N content is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com