Tool for preventing carbon brush from direction error in installation

A technology of installation direction and carbon brush, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of poor contact between carbon brushes and slip rings, ineffective and timely detection, unreliability, etc., to save manual inspection and direction testing process, avoid rework and material cost, control the effect of outflow of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

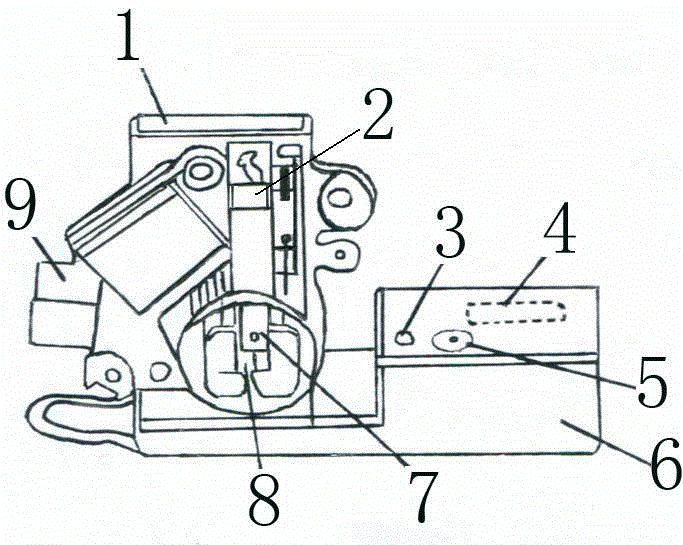

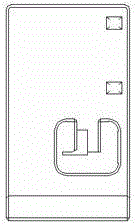

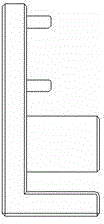

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: the present invention comprises regulator 9, carbon brush length control block 1, PCB trigger plate 8, alarm device 6, carbon brush 2 is housed on regulator 9, and carbon brush length control block 1 is also housed on regulator 9 , the PCB trigger board is installed on the carbon brush length control block 1, and the right end of the regulator 9 is provided with an alarm device 6, and the alarm device 6 has a built-in light-emitting diode 3, a piezoelectric active buzzer 5, a battery 4.

[0026] The battery is 9V. The light-emitting diode is 5V, and the piezoelectric active buzzer is 3-15V.

[0027] The PCB trigger board 8 is connected to the light-emitting diode 3 and the piezoelectric active buzzer 5 through wires. When the direction of the regulator carbon brush 2 is reversed, the high head of the carbon brush is pressed on the PCB trigger board 8, so that the positive trigger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com